Injection Compression Molding: Who will be first?

A plastic cup as a food container has several journeys ahead of it - and it's always about efficiency. The efficiency with which it is produced, stacked and transported to the bottler. The efficiency with which it runs through the filling line there and is transported to the supermarket shelves together with its contents. And the efficiency with which it finally passes through a sorting and recycling plant on its way back into the cycle.

In the PDF article in the trade journal “Plastics Insight”, you can read why an ICM thin-wall cup is more efficient and sustainable than a thermoformed cup with a cardboard sleeve.

ICM thin-walled cup (Fakuma 2023)

The article describes an application that we presented at Fakuma 2023. Watch the video to find out the key highlights of this exciting packaging solution.

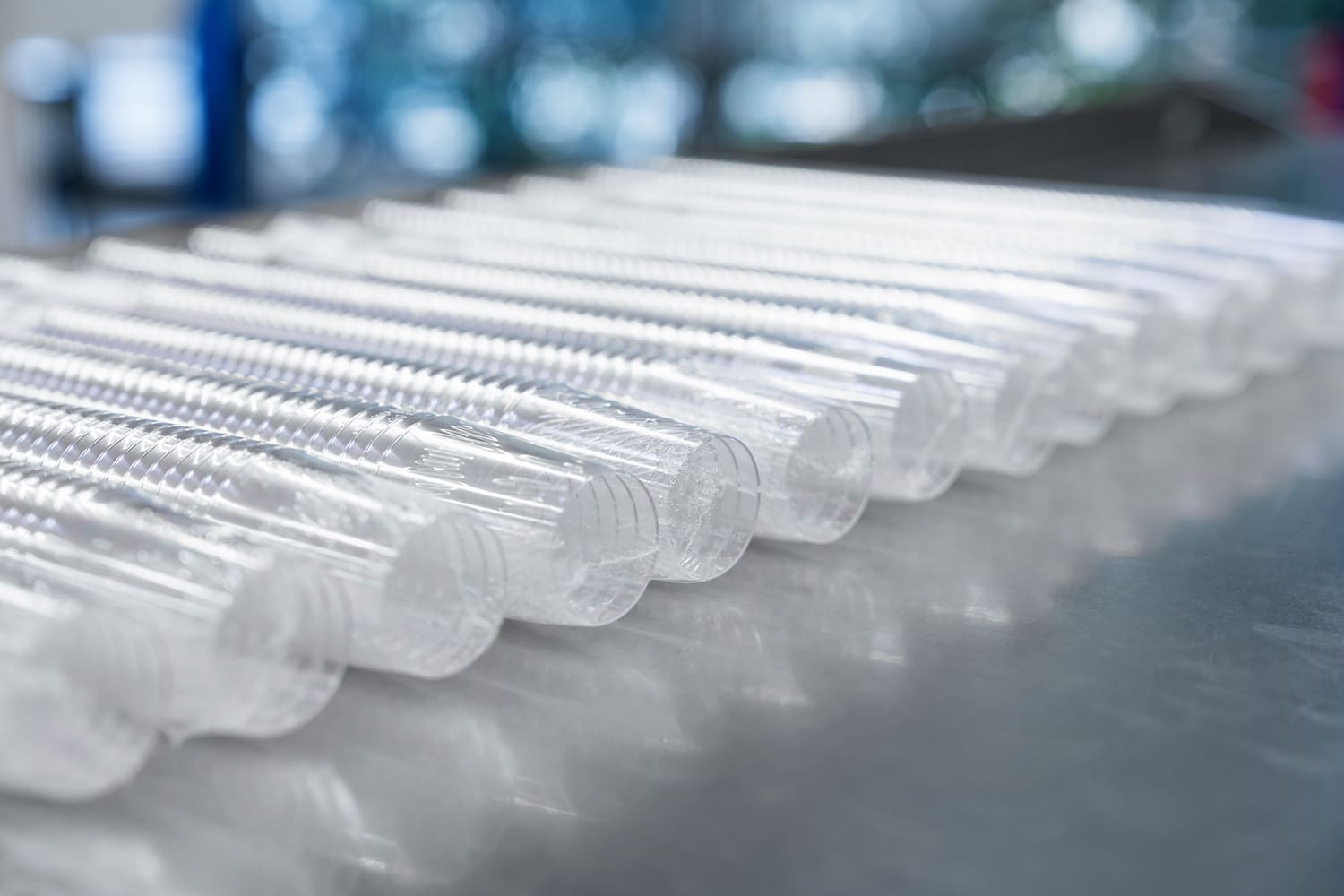

Transparent, thin-walled and highly recyclable: Packaging made from PET

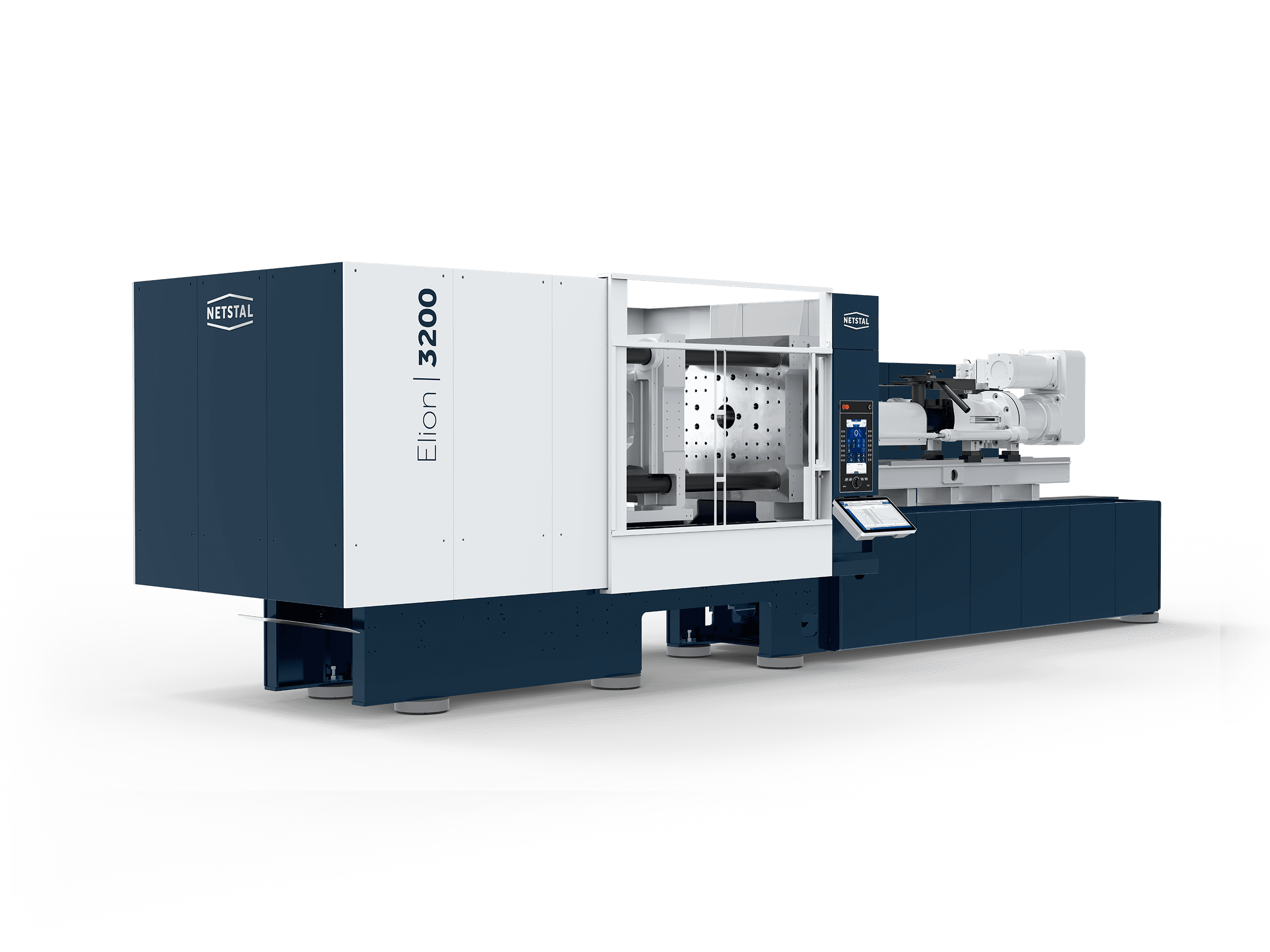

As a manufacturer of plastic packaging, do you want to make products from PET in the future or are you generally interested in possible alternatives to PP? Then you should plan a visit to Netstal at the NPE. In Orlando, we and our system partners will be demonstrating what sustainable and recyclable thin-wall packaging can look like. At our stand W223, we will be producing a thin-wall cup made of 100% PET on a hybrid Elion 3200. The transparent cup can be processed together with empty PET bottles into high-quality recyclates.

The recycling rate for thin-walled plastic packaging, such as cups for dairy products or spreads, is still low worldwide. This contrasts with PET bottles, which play a pioneering role in recycling. Across Europe, half of all PET bottles placed on the market were already recycled in 2020. The trend is also rising worldwide. However, if all types of PET packaging are considered, the rate is still 35% (source: Statista). Due to its good recyclability and the established recycling systems in several countries, the idea of using PET for thin-walled packaging and making it specifically recyclable is an obvious one. PET packaging must meet certain criteria so that it can be easily collected via the established collection systems and processed into rPET regranulate in the recycling plants together with PET bottles. This is an important prerequisite so that new bottles and packaging can be created from all PET containers.

"Clear packaging or the absence of color additives is preferred for PET packaging in order to achieve the purest possible quality of rPET. At the NPE, we will be showing such a PET cup that is optimized for recycling."

Reto Gmür, Produktmanager Packaging

The thin-walled PET cup weighs around 15 g

Sustainable PET thin-wall cup produced in a climate-friendly way

We have developed such a recycling-optimized solution for the NPE and in collaboration with our system partners. The clear cup weighs around 15 g and has a filling volume of 450 ml. We process virgin PET from the Eastman Chemical Company. We put the cups into the NPE recycling program so that the material remains in the PET cycle without loss. The labels are also made of PET and are provided by the Belgian IML specialist Verstraete. Our Canadian partner StackTeck provides the test mold with two cavities as well as the IML robot that inserts the labels into the cavities and removes and stacks the finished cups.

The PET cup is injection molded in a cycle time of around 4 seconds on our Elion 3200. With its electric toggle clamping unit and hybrid injection unit, the injection molding machine delivers the necessary speed, performance and dynamics. By recuperating kinetic energy from the clamping unit, the Elion is one of the most energy-efficient injection molding machines on the market. In high-speed applications, the Elion is in efficiency class 8 and higher of the latest Euromap 60.1 standard. The unit with RFC injection control shines with its leading shot-to-shot consistency. This is only available from Netstal in this form: The force-dependent pressure changeover is independent of the material properties and enables our customers to keep the part weight within tight tolerances at all times. You do not pay any extra for the leading Netstal precision, because the highest precision has been standard at Netstal for decades.

High-performance and energy-efficient injection molding machine: the Elion 3200

The Elion 3200 is equipped with the optional adaptive pressure reduction. This optional function helps you to save energy. If the pressure reduction is activated, the hydraulic system pressure is permanently adjusted to the optimum point. This option offers you enormous advantages. With a lower pressure, the axles of the machine are less heavily loaded. This has a positive effect on availability. However, the main benefit is the further reduction in power consumption. You produce particularly efficiently and at the lowest unit costs.

World record: Alltrista manufactures 128 beverage caps every 1.9 seconds

At the NPE you will experience high-performance injection molding in its purest form at Netstal. Together with our system partners and customer Alltrista®, we will be presenting the world's most powerful production system for lightweight beverage closures. The key data are impressive: 26mm water closures, 128 cavities, 1.9 second cycle time, 25 % material savings. Read the story to find out how this project came about.

At Alltrista, the production of 26mm water closures is running at full speed on two production lines. Anyone familiar with the subject quickly realizes that a very special application is in use here. You rub your eyes in amazement: is this a mold with 128 cavities that is moved here with a cycle time of 1.9 seconds? Can that be true? Yes, it is: Alltrista is the first company in the world to produce over 3 billion closures with a program like this. To be precise: 3.1 billion caps. We can announce this with a broad chest: We are proud to be part of this success story with our leading injection molding technology.

But let’s hear from our customer first.

“We wanted to be the first manufacturer to operate a system with 128 cavities in less than 2 seconds. With Netstal, z-moulds and Intravis, we have found the best system partners for this project. Each company is a leader in its field and the combination is unbeatable from our point of view. We simply thought: if this is to work, we need exactly these three partners. With the first two 128-cavity systems, we are now producing more efficiently than ever before, can deliver at any time and delight our customers. This has given us an enormous competitive advantage.”

Christopher Navratil, CTO at Alltrista’s parent company

Innovative mold-machine combination pushes physical boundaries

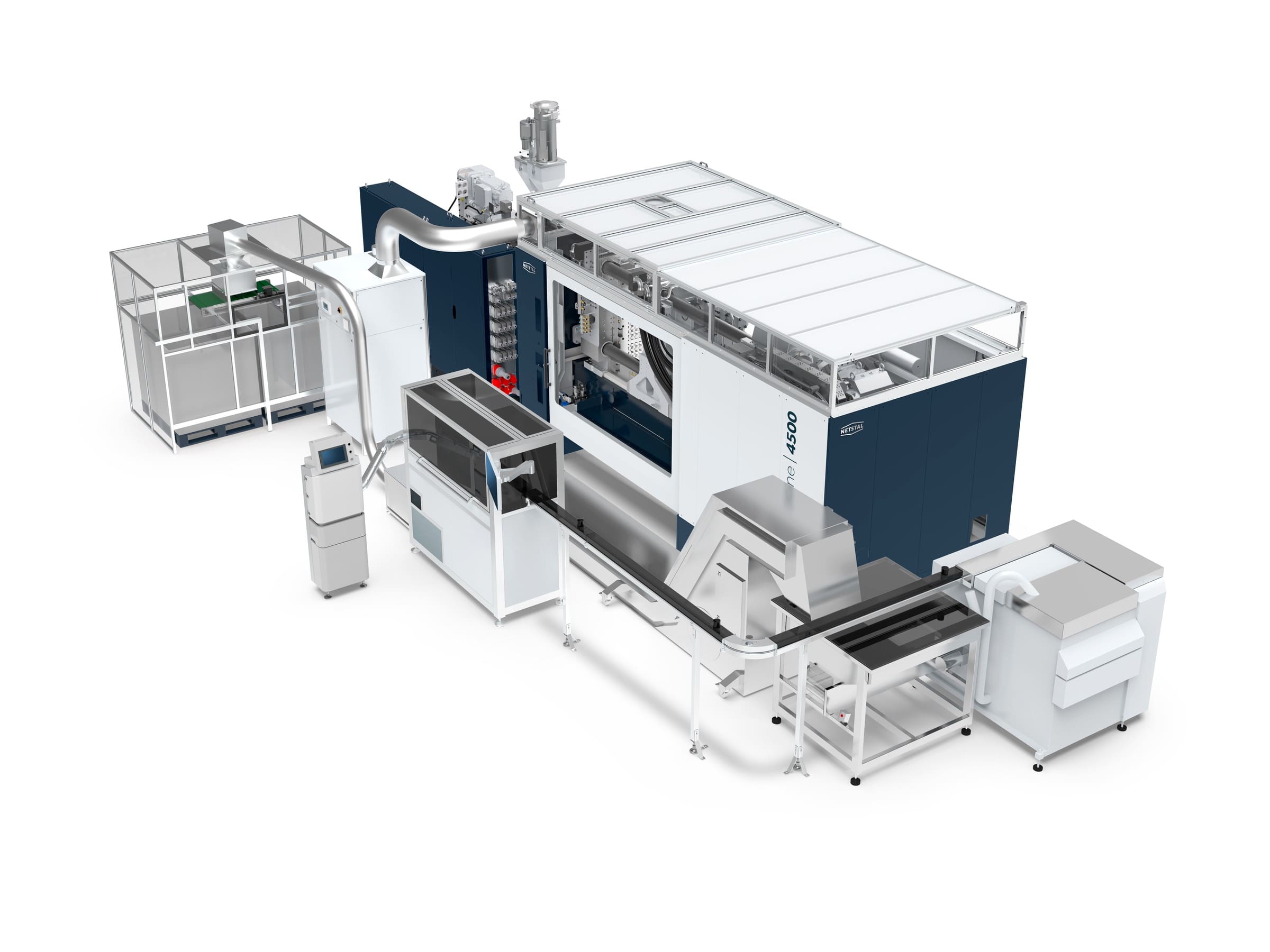

Let’s go into a little more detail. Water closures of the 26 mm type are produced for still water that is filled into PET bottles. Thanks to an innovative design, z-moulds was able to make its mold as small and light as a 96-cavity mold. This results in decisive advantages for the user. Compared to previous 128-cavity molds, the mold fits into a machine with a smaller tie bar distance. The compact design of the mold also means that less mass needs to be moved. An important prerequisite for the fastest possible cycle times. Consequently, running 128 cavities with a cycle time of less than 2 seconds is a world first. At Alltrista, the lines run at around 1.9 seconds. Occasionally it is also 1.85 seconds. The complete production system also requires very little floor space. Each line produces 1.55 billion closures per year on around 50 square meters. More output per square meter of production area is currently not possible.

Maximum productivity in a small space: At around 50 square meters, the Alltrista production system only requires a small footprint

Significant energy savings and 25% less plastic

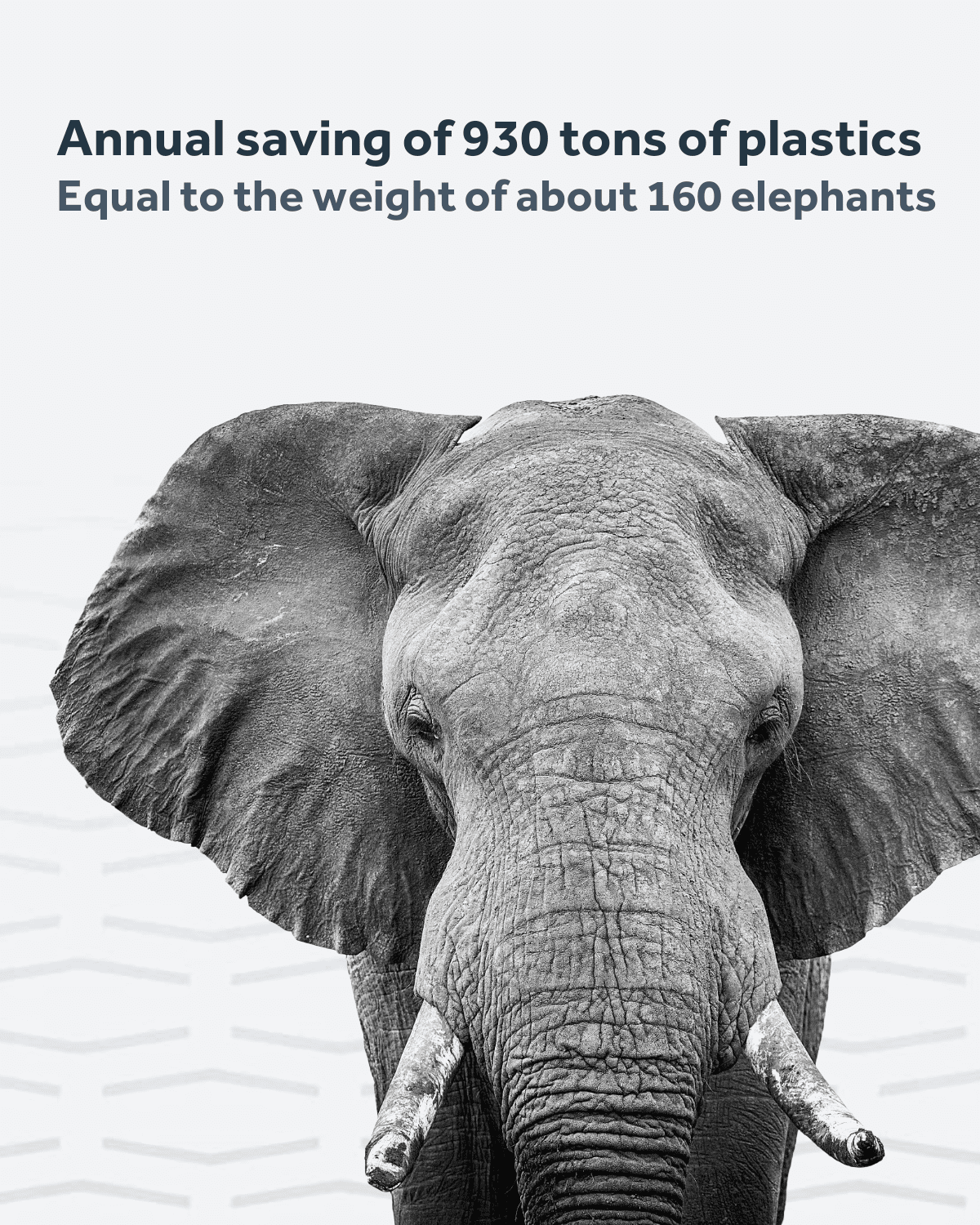

More output is a great thing. Add to that savings on materials and electricity and you have efficiency at its peak. Comparative measurements have shown that the Elios 4500 with 128 cavities consumes around 12% less electricity than comparable machines from the competition. However, these were equipped with only 96 cavities. In addition, the application engineers at Alltrista were able to make the closures 25% lighter and therefore much more sustainable without compromising their function. Based on the full programm productivity of 3.1 billion closures per year, Alltrista saves over 930,000 kg of material. This corresponds to the weight of approximately 160 adult African elephants.

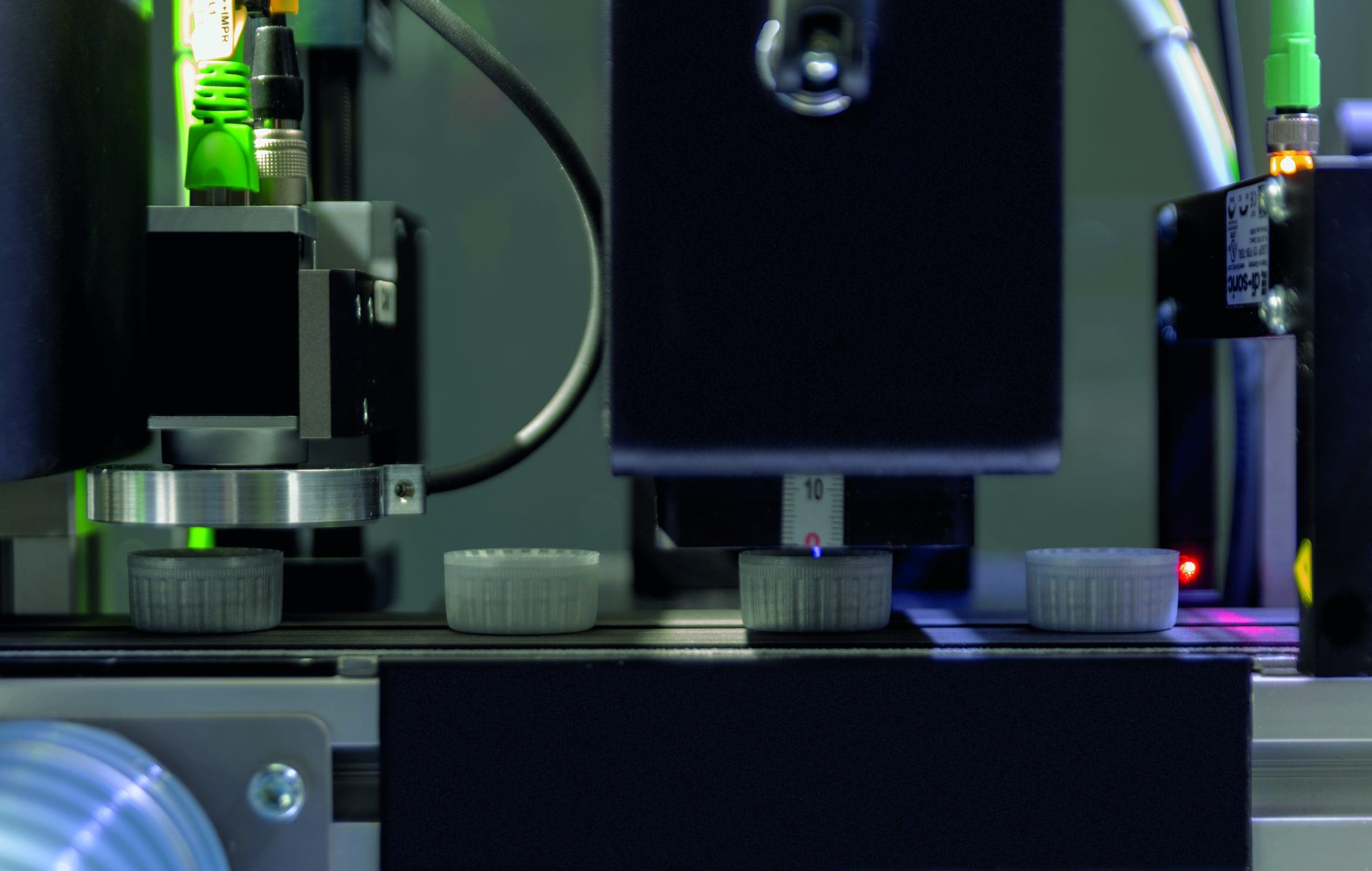

Intravis high-speed downstream quality control

However, the enormous number of caps is not yet ready for dispatch immediately after demolding. Before they can be filled into octabins, the closures pass through the downstream equipment of our system partner Intravis. The CapWatcher Q-Line carries out a comprehensive 360° full inspection of the closures. Today’s computing power makes it possible: up to 80 closures per second are checked for more than 40 quality criteria with an accuracy in the hundredth of a millimeter range. The cavity-related inspection is carried out with up to nine high-resolution cameras. An enormous amount of data that is processed in real time. The high performance gives Alltrista the certainty at all times that the closures are flawless immediately after production and that customers are only supplied with good parts.

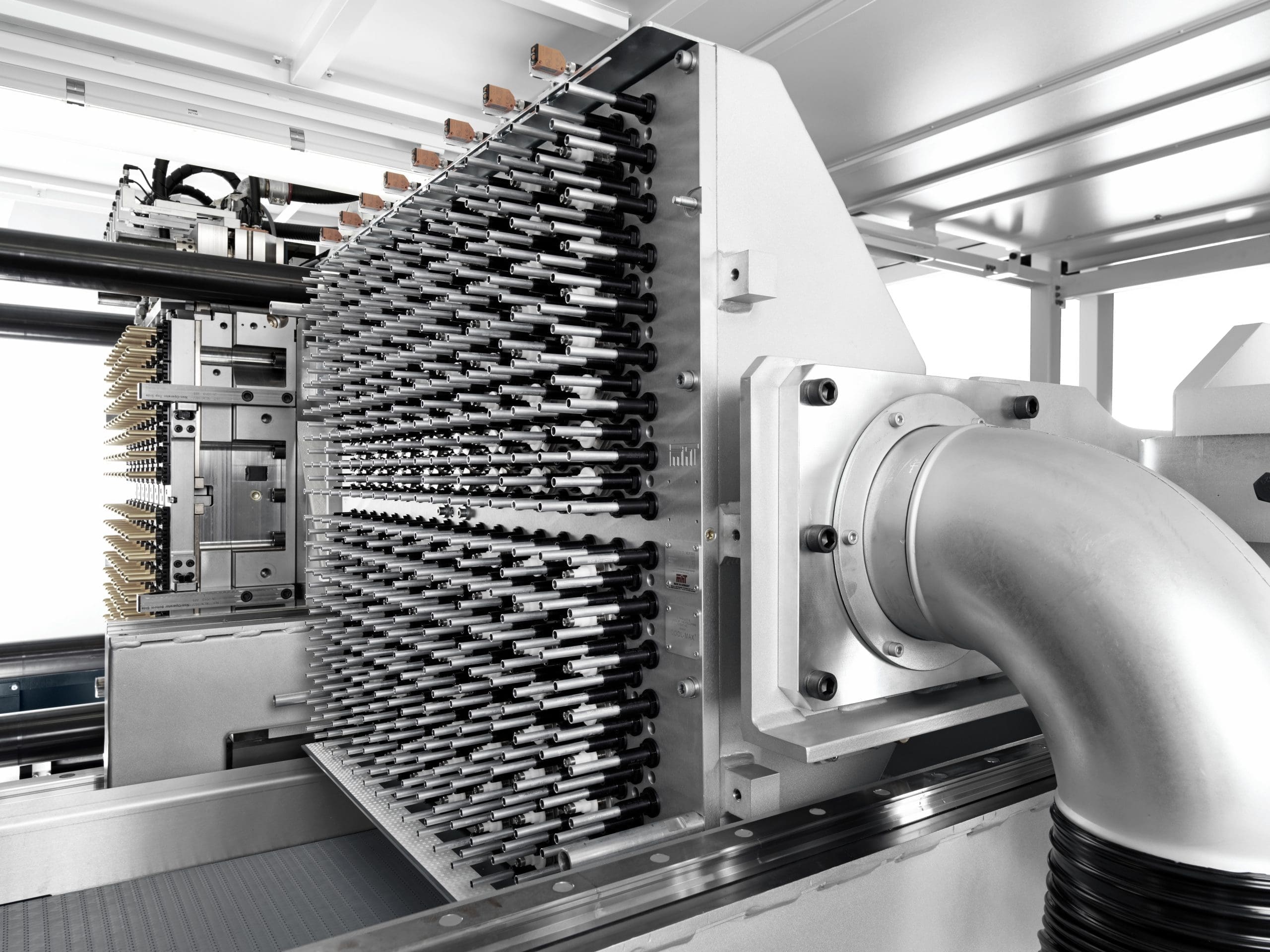

A look inside the CapWatcher Q-Line. The system uses 9 high-resolution cameras to check up to 80 caps per second for more than 40 quality features

Alltrista: Innovative contract manufacturer from South Carolina

All in all, the Alltrista production system for 26 mm closures is the new benchmark in terms of speed, productivity, efficiency and sustainability. Two identical system solutions for closure production are currently in production at Alltrista. Alltrista Plastics LLC specializes in innovative, high-volume precision manufacturing. From rigid packaging and custom molded solutions to assembly, filling and kitting, Alltrista supports customers in the medical, healthcare and consumer goods industries with a wide range of products and services. The company’s ability to assemble strong teams on a project-by-project basis allows it to be flexible on even the most challenging orders.

Christopher Navratil confirms: “This closure application is proof of our innovative strength and our unbridled desire to keep pushing the technological boundaries. We are proud that, together with the experts from Netstal, z-moulds and Intravis, we were able to increase productivity by at least 30 percent in this project. For us, this is a prime example of how companies from the USA can work successfully with partners from Germany, Austria and Switzerland.”

Alltrista attaches great importance to the continuous improvement of its own sustainability. The company was audited by Ecovadis in 2023 and received the silver medal for its sustainability performance to date. Alltrista ranks in the 88th percentile of all companies assessed by Ecovadis and among the top 7% of peer companies.

Witness the Alltrista production system live at the NPE in Orlando

As mentioned at the beginning, we will be presenting an identical production system for 26 mm closures at our NPE stand. Alltrista will have its own staff on our booth to provide information from the customer’s perspective. For detailed information on all the company’s services, we also recommend a visit to booth S22065 in the South Hall, where Alltrista will be showcasing its full range of contract manufacturing and injection molding products and services.

Visit our NPE exhibitor profile and plan your visit:

CAP-Line

At the NPE you will see a Netstal machine labeled CAP-Line for the first time.

With the CAP-Line, we offer specifically pre-configured injection molding machines for closure applications. The CAP-Line 4500 on our stand is based on the high-performance Elios platform and is equipped with various features for the efficient production of beverage closures.

The CAP-Line 4500’s all-electric toggle-type closing unit with a drying time of 1.4 seconds enables cycle times of less than 2 seconds. Thanks to the optimized barrier screw, we can use a smaller injection unit. The new screw design ensures a higher plasticizing performance and a better degree of homogenization. Further options are available for individual optimizations, such as our four-button Smart Operation or the adaptive system pressure reduction, with which you can achieve additional energy savings.

With the new concept for the CAP-Line, we are aligning our portfolio even more closely with our customers’ applications. As a closure manufacturer, you benefit from a system that is individually tailored to your application. However, pre-configuration speeds up the consultation and quotation process so that delivery times for the machine are as short as possible.

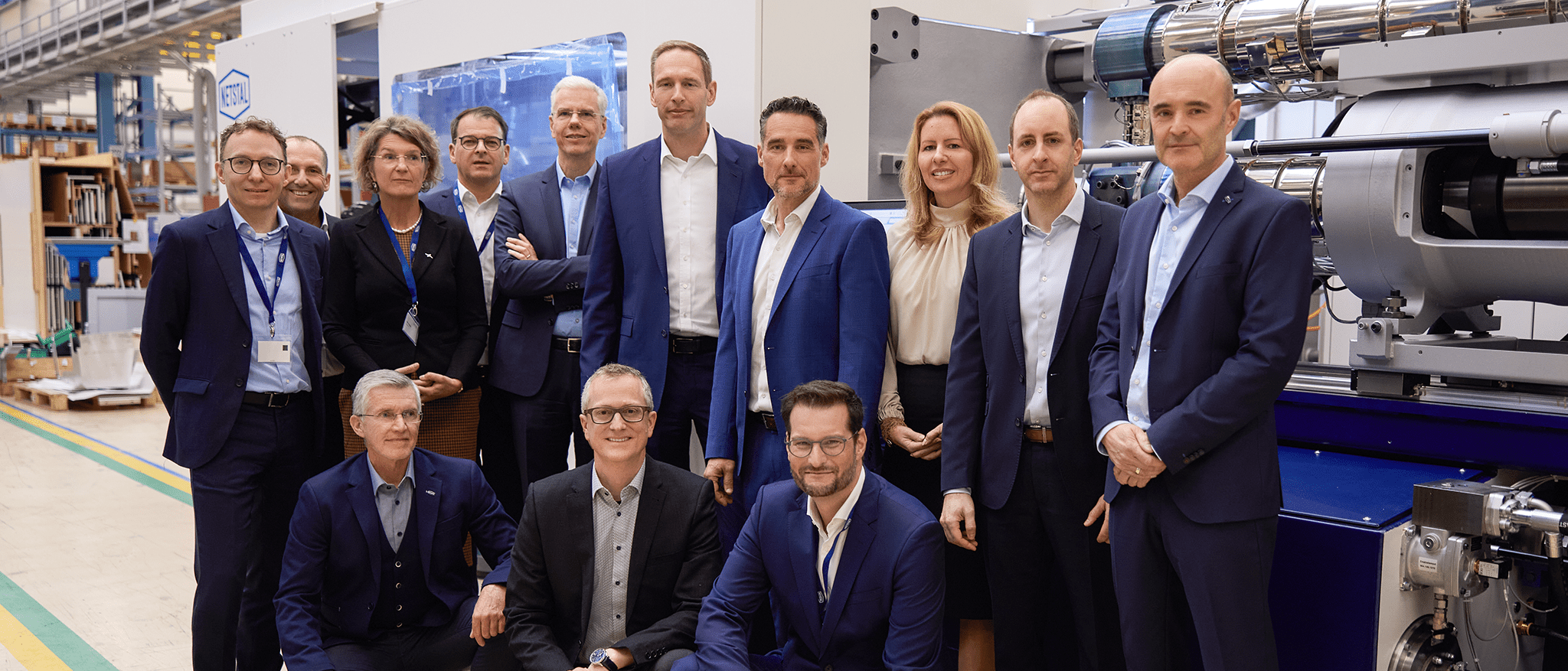

Netstal becomes a member of the Krones Group

Netstal will have a new owner: Krones acquires 100 percent of the Netstal Group from KraussMaffei. The takeover agreement was officially signed on February 6. The transaction is expected to be completed in the first half of the year. Our customers in all application areas will benefit from the opportunities arising from this change.

We will not have to introduce Krones to our customers in the beverage industry. This may be different for Netstal users and our partners from the thin-wall packaging and medical technology sectors. That is why we are pleased to offer a brief overview of the Krones Group: Krones is the market leader in lines and machines for the production, filling and packaging of beverages and liquid foodstuffs in PET and glass bottles as well as beverage cans. With its products, the German company covers the entire production, filling and packaging process as well as the material flow in the manufacturing plant and integrates the corresponding IT systems. It also carries out complete factory planning projects for the beverage industry. Headquartered in Neutraubling, Bavaria, the company employs around 18,000 people worldwide. Consolidated revenue in 2022 amounted to 4.209 billion euros. Krones AG is listed on the Frankfurt Stock Exchange and is currently included in the MDAX share index.

Looking forward to a successful collaboration (from left): Danijela Karelse (CFO Netstal), Renzo Davatz (CEO Netstal), Christoph Klenk (CEO Krones) and Uta Anders (CFO Krones)

The Krones Group stands on an extremely solid economic and technological foundation and can look back on a very successful development over the past decades. We are convinced that Netstal can only benefit from this new foundation in order to achieve the targeted growth in all areas.

“This transaction is a milestone in the long history of Netstal. Krones opens up strategic perspectives that were previously not possible. The potential for more customer benefits and growth in the beverage sector is obvious. The opportunities in the medical and thin-wall packaging applications are equally exciting. It is a pleasure for me to continue the strategic direction we have taken together with Krones to an even greater extent.”

Renzo Davatz, CEO Netstal

Leading solutions for the beverage and packaging industry as well as medical technology

However, major changes can also lead to questions. We would therefore like to emphasize at this point: With Netstal, we will continue to focus on you and your needs. Your personal contacts in sales and service will continue to be available at the headquarters in Näfels and in the subsidiaries. The processing of orders and projects will also not be affected. You will always receive leading technology from us in proven Netstal quality.

Our market orientation will not change. Krones would like to work with us to further develop the Netstal strategy and lead it to success. This applies to all strategic application areas. Netstal will continue to offer leading solutions for the efficient production of PET preforms, beverage closures and thin-wall packaging. In medical technology, Netstal is excellently positioned in high-speed mass applications for laboratory and consumable materials. This market position is to be further strengthened in the future. With its leading injection molding technology for medical applications and thin-wall packaging, Netstal supports Krones’ strategy of diversifying into the medical/pharmaceutical market as well as the food and personal care sectors. Netstal will continue to manage its business independently, benefiting from Krones’ international footprint and economies of scale.

Injection Molding Competence Center Näfels

Despite a challenging environment, we believe we are well equipped for the future. With Netstal, we have a competitive product portfolio and are constantly working on further innovations. Always with the aim of further increasing your added value. Under the umbrella of Krones, we will continue to expand our leading position in the top performance segment. Our headquarters in Näfels will be further developed into an injection molding competence center. This will ensure your supply of innovative injection molding technology and associated services as well as digital enhancements for applications in the top performance segment.

We will be happy to answer any questions you may have on this and other topics.

You can find more information on our leading solutions on the industry pages for preforms, closures, packaging and medical technology.

All information about Krones can be found at www.krones.com.

A story about quality: pipette tips from Hamilton

Hamilton has been producing liquid handling consumables for the global market at its new site in Domat/Ems since 2018. Hamilton relies on Netstal for the efficient production of its precise CO-RE II pipette tips. Satisfaction is not only ensured by the high-precision injection molding machines, but also by the reliable service and partnership-based cooperation.

The new Hamilton building in Domat/Ems makes an impressive impression with its glass facade. Even from the highway, you can see that this is not just an office complex like many others – it is also a production facility. And it is high-tech. Directly behind the glass facade, the Netstal machines are lined up lengthwise on the first floor. A beautiful and high-quality presentation.

Hamilton in Domat/Ems, Canton Graubünden, Switzerland

Hamilton manufactures pipette tips from its CO-RE II range using the all-electric machines in the Elion series. The innovative technology offers maximum precision when picking up and positioning tips. With an extremely robust and airtight lock-and-key mechanism, Hamilton tips are attached to the independent pipetting channels with virtually no effort. The optimum seal enables highly precise and uniform liquid transfer steps. Hamilton’s CO-RE II tips have a fine, thin tip that facilitates the dispensing of micro volumes.

An employee checks the cavities in the injection mold

However, it is not just the tips themselves that have been continuously developed. Hamilton also considers the entire underlying process technology, which is fully automated from the provision of the granulate through to packaging and storage, to be innovative.

"We are absolutely convinced of the high performance and precision of the Netstal injection molding machines. At the same time, we are very satisfied with the partnership-based cooperation and the services provided. If we have a problem, we can always rely on Netstal to work on a quick and optimal solution for us."

Simon Freitag, Plastics Specialist Hamilton Bonaduz AG

Hamilton CO-RE Tip Production in Switzerland, Domat/Ems

Safety and quality go hand in hand

Hamilton manufactures its consumables in an ISO Class 8 clean room that complies with ISO 14644, ISO 9001 and ISO 13485 standards. Hamilton does not rely solely on statistical quality analysis to ensure the highest product quality. Each pipette tip is monitored in the manufacturing process for the concentricity of its opening and the absence of burrs from the casting process. The medically equipped injection molding machines are adjacent to the centrally located clean room. The pipette tips enter the clean room via the removal systems. There, the tips are further processed separately by cavity and their quality is checked in-line. The next step is the packaging process. 96-well tip trays are loaded, packed in blister frame racks and sealed with a paper lid.

96-Well-Tip-Tray mit 300 μL CO-RE® II tips

The sealed blister frame racks are then transported to the fully automated packaging system above the clean room. Blisters and outer cartons are “married” by means of unique coding, so that complete traceability is always guaranteed. The packaging units are then transported on a conveyor belt to the high-bay warehouse, which is 40 meters high and has a capacity of 12,000 pallets.

300 % increase in capacity within 2 years

With the outbreak of the coronavirus pandemic in 2020, the global demand for consumables exploded to cope with the increased volume of PCR tests performed. At this time, the Hamilton team in Domat/Ems was also under great pressure. Within 2 years, the production capacity for pipette tips was tripled. This was achieved by doubling the number of injection molding lines and production personnel. Netstal was able to contribute to this success. Even in normal times, specially equipped injection molding machines are almost impossible to procure at short notice. At that time, the situation was becoming increasingly difficult due to interrupted supply chains. This is where Netstal’s used machine program came into play. To bridge the delivery time for the new machine ordered, a used rental machine was put into operation in Domat/Ems at short notice. Subsequently, further new machines were sent to Domat/Ems and the USA to produce pipette tips.

At its peak, production in Domat/Ems ran day and night in four shifts, 365 days a year. As demand has now fallen again somewhat, there is a break at weekends. An interruption that would not be necessary from the injection molding machines’ point of view.

About Hamilton

Hamilton Bonaduz AG develops automated pipetting robots for handling a wide variety of liquids. With our sensors, we are also an innovation leader in the field of process analytics. Hamilton Storage GmbH, which belongs to Hamilton Bonaduz AG, is a leading provider of automated sample storage systems for research laboratories, pharmaceutical and clinical diagnostic companies and government institutions.

Hamilton’s products are known for advancing the life science, clinical diagnostics, forensics, biotechnology and biopharma industries, offering reliability, performance and flexibility.

Hamilton utilizes state-of-the-art manufacturing facilities in Reno, Nevada, and Bonaduz, Switzerland, as part of its ongoing commitment to quality and has achieved global ISO 9001 certification. Hamilton is privately held with headquarters in Reno, Nevada, Franklin, Massachusetts, and Bonaduz, Switzerland, and offices around the world.

Images: Hamilton Company

PET preform production: into the future with side removal

In September 2020, we presented the new PET line with side removal. Over the past three years, we have been able to convince existing and new customers of the benefits of the state-of-the-art preform system and successfully placed many systems on the market. We are now expanding the series with the PET-Line 5000.

“If you walk through our PET assembly hall, you mainly see our new side-entry PET Line. The predecessor model, which is based on the top-entry principle, can only be seen occasionally, reports PET Product Manager Stefan Kleinfeld. The market is opting for the most advanced technology. “With the higher productivity, lower power consumption, optimum processing of PET recyclates and excellent compatibility with existing molds and post-mold cooling stations, we offer our customers convincing arguments. We are very satisfied with the development of sales figures to date,” emphasizes Stefan Kleinfeld.

Our new video gives you an overview of the many advantages of the PET-Line:

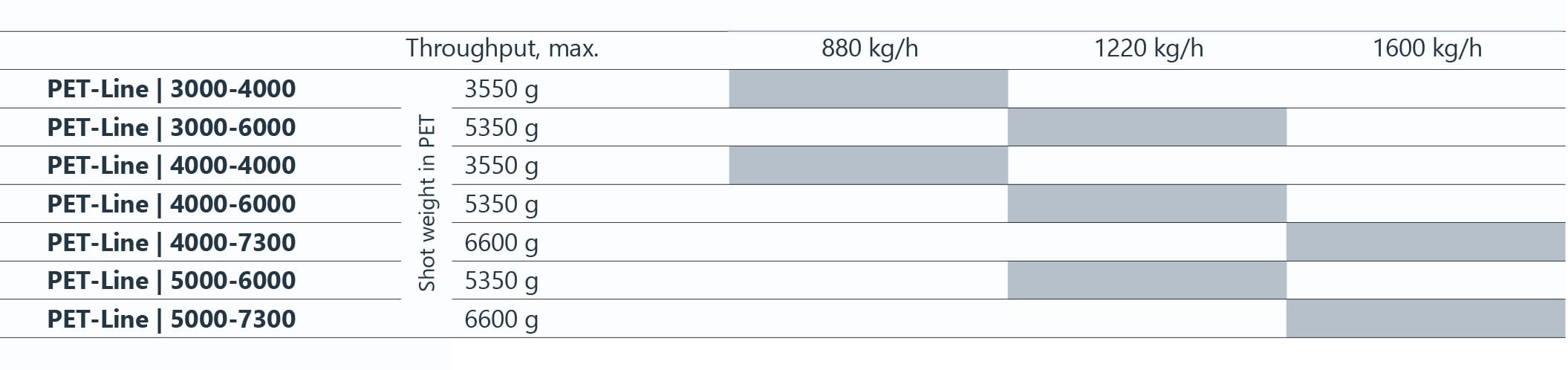

PET-Line with 5000 kN clamping force extends the series

The future clearly belongs to the PET-Line with side discharge. In order to meet market requirements even better, we are expanding the series. In addition to the existing models with 3000 kN and 4000 kN clamping force, production of the 5000 kN clamping force variant will start at the end of 2023. Thanks to the greater plasticizing unit, preform manufacturers can fill large molds safely and precisely. To optimally meet different market requirements, our customers can combine the three clamping force sizes with different units. There are currently seven combinations to choose from.

Variants:

We provide you with expert support in configuring a PET-Line that optimally fulfills your tasks. Find the right contact person in your region:

Production of the predecessor model (PET-Line top-entry) will be discontinued as planned at the end of 2024.

A trusting and lasting cooperation

Manfred Schägner GmbH has relied on Netstal injection molding machines to produce food packaging and medical products for many years. In addition to the technological advantages of Swiss technology, the company values the trusting cooperation and good customer service.

“We have always felt that we are in good hands with Netstal. The machines are powerful and reliable. And if there is ever a problem, Netstal is always there for us and organizes a solution as quickly as possible,” say Christian and Manfred Schägner in unison. In Steinmauern, Baden-Württemberg, the family business with 70 employees produces food packaging, drinking vessels and various plastic articles for the pharmaceutical and medical industries. The company’s own mold construction facility to produce injection molds completes the portfolio. The company serves customers in Germany and abroad. Almost half of production is exported.

"We have been working with Netstal machines for many years. With Netstal, we consistently produce with maximum efficiency. In addition to the quality of the machines, we appreciate the excellent customer service."

Manfred and Christian Schägner

Sustainable food packaging produced efficiently

The machine park currently includes 28 Netstal injection molding machines with clamping forces between 600 kN and 4200 kN. “Our Netstal machines are linked to fully automatic removal systems and packaging systems. This is how we ensure a high standard of quality and hygiene in the production of food packaging and beverage containers,” explains Christian Schägner. The products should become ever more sustainable. That’s why, in addition to production, Schägner also places a strong focus on new developments, trials and research into recycling and the use of alternative materials and reusable items. All raw materials used are already fully recyclable.

Schägner products can be recognized by the familiar MS logo on the bottom. Items for multiple use are becoming increasingly important. Depending on the product, the beverage containers, plates and cutlery are designed for up to 125 wash cycles. Afterwards, the products made from mono-materials can be recycled.

Drinking cups from Schägner

Hygienic injection molding production with direct transport to the clean room

Schägner has been assembling some of its pharmaceutical products in a cleanroom since 1991. In 2021, a state-of-the-art class 8 cleanroom in accordance with DIN 14644 with approx. 500 square meters was put into operation to expand capacity. Due to the location of the cleanroom, it is now possible to transport the products manufactured in production to the cleanroom via encapsulated conveyor belts.

All-electric Elion 2200 in medical configuration

The product enter the clean room via encapsulated conveyor belts

“Modern and precise injection molding machines are a basic requirement for reliable production with stable production parameters. We recently invested in two new Elion 2200 machines in a medical version,” reports Manfred Schägner. The two all-electric machines are positioned directly next to the clean room. The finished products are transported directly to the clean room for further processing via an encapsulated conveyor belt. In order to meet the high standards, both machines are equipped with a laminar flow hood above the closing unit.

The assembly and packaging systems used meet the highest pharmaceutical standards and are a prerequisite for high-quality products. Schägner is certified to ISO 13485:2016 for the design and development, production and distribution of medical application aids for tablets, ointments and liquids.

Further processing in cleanroom class ISO 8

Schägner offers its customers in the pharmaceutical industry everything from a single source. From the initial exchange of ideas, through the planning, development and manufacture of the production tool, to the production and packaging of the product, everything is done in-house. Standard products are supplied to well-known companies in the pharmaceutical industry worldwide. These include applicators for creams, tablets and rectal cannulas. Customized special products have also been part of the range of services for decades. These include special applicators for capsules and tablets, tubes for liquid medicines in the field of veterinary medicine, dosing spoons and infusion bottle holders.

When you talk to Christian and Manfred Schägner, you can tell that Schägner and Netstal are simply a good match. We would like to thank them for their trust in Netstal and look forward to many more years of successful collaboration.

Photos: Manfred Schägner GmbH

Packaging highlight: 200 g ICM thin-wall cup

The Swiss Emmi dairy fills various products such as yogurt or skyr in 200 g pots, which are produced using conventional injection molding. When evaluating more cost-effective and sustainable alternatives, a cup produced using the injection compression molding (ICM) process came into play. Even in direct comparison with a thermoformed cup with a cardboard sleeve, the Netstal solution offers numerous advantages.

Solution from Netstal:

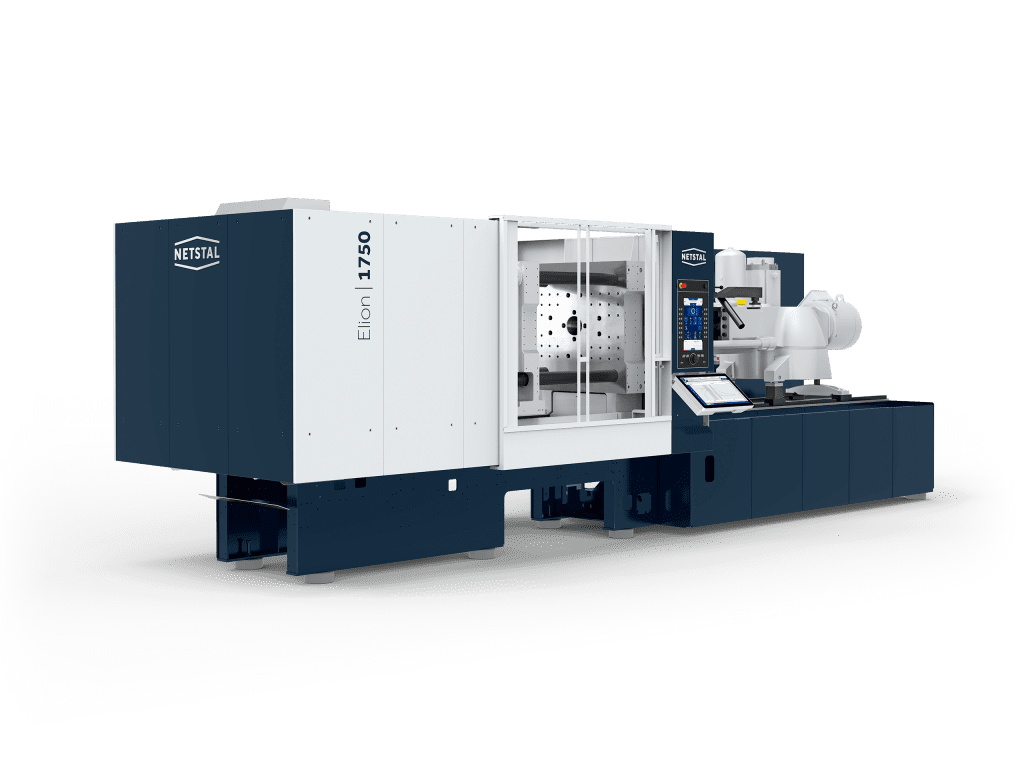

The ICM application was realized in cooperation with several system partners. We presented it as a running application at Fakuma 2023. For this we adapted a hybrid Elion 1750 to the injection compression molding process. The ICM mold with 4 cavities comes from Glaroform. Beck Automation provided the IML handling system with integrated camera inspection. The laminated PP label from iPB detaches itself during the recycling process.

Industry partner Emmi filled pre-produced sample cups on its filling line shortly before Fakuma and delivered them to Friedrichshafen. On our exhibition booth we served our guests finest blueberry skyr filled in show cups. Tasty proof that our solution works perfectly in practice.

Results ICM compared to 200 g cups in standard injection molding:

- The cycle time is reduced by approx. 14 % compared to standard injection molding

- Plastic consumption falls by approx. 34%

- 27 % more parts per packaging unit

- 33 % less CO2 equivalents1

Results ICM vs. 200 g thermoforming cup with cardboard sleeve

- Plastic consumption is reduced by approx. 20 % (both cups without label)

- The labeled ICM cup is around 40 % lighter than the labeled thermoformed cup (5.96 g vs. 9.87 g)

- Around 22 % lower power consumption per kg of material throughput

- 150 % more parts per packaging unit

- 28 % less CO2 equivalents1

- One-step process: the finished labeled cup comes directly from the injection moulding machine

Conclusion:

With this application, we can prove that cost efficiency and sustainability go hand in hand in injection molding. The thin-walled ICM cup has a significantly better carbon footprint, even compared to the thermoformed cup with a cardboard sleeve.

Because it is made of 100% PP, it is completely recyclable. This has been certified with the top grade A+++.

Download: Recycling certficate (German)

Injection compression molding offers manufacturers of plastic packaging unique opportunities. You too can increase your efficiency and optimize the ecological footprint of your production with ICM.

Our experts will be happy to provide you with individual advice.

1 Estimated carbon footprint for polymer, label, production in Germany (8000 h / year), transport distance 628 km

Our highlights at Fakuma 2023

Visit us at Fakuma (Hall B3, Booth 3119), where we will be using the injection compression molding process to produce thin-wall packaging specially designed for the circular economy. This process allows you to produce packaging with minimal wall thickness and save valuable resources. With the new Axos 9 control generation, you can take efficiency and precision in your production to a new level. Visit our booth and get inspired.

Discover lightness: Our innovative 200 g yogurt cup presents itself in a feather-light design. With its part weight of only 5.4 g, it sets new standards. What makes this cup particularly sustainable: both the cup and the label are made of 100% recyclable polypropylene (PP). This allows for easy recycling and strengthens your contribution to the circular economy. Unlike conventional in-mold labels, the label does not stick in the recycling process. It detaches without affecting the PP recycling stream. Thanks to efficient separation of the ink particles from the pure PP, high-quality regranulate can be produced.

The use of injection compression molding (ICM) reduces the weight of the cup by an astonishing 34%. This innovative approach goes hand in hand with our sustainable vision. In addition, by combining the ICM process with product optimizations, we have reduced the packaging volume by an impressive 27% – another step towards sustainability and resource conservation.

Sustainable cups, efficiently manufactured

Experience our environmentally friendly cup, produced with energy-efficient production processes. The thin-wall packaging for dairy products is produced in 4 cavities and requires only 2.7 seconds per cycle – thanks to our Elion 1750 machine with hybrid injection unit. At Netstal, we focus on reliable performance and set standards in terms of energy efficiency. Our machines work precisely and economically to conserve resources and ensure sustainable production. With the optional adaptive system pressure reduction, we have further improved the efficiency of our hybrid machines. The new function is a technological highlight that always determines the optimum point in automatic mode and adjusts the pressure in the hydraulic system accordingly. This results in minimized energy consumption to provide the required system pressure, depending on the application. At Netstal, we are committed to sustainable solutions that are both efficient and environmentally friendly.

The application is the result of a successful cooperation with renowned high-end system partners. These include Glaroform, Beck Automation, SABIC, IPB Printing, motan, Regloplas and Uniform Color. Together we have worked on this future-oriented solution. A key development partner in this collaboration is Switzerland’s Emmi AG, one of the largest dairy product bottlers and a pioneer in the food industry. The specifications for this innovative packaging were developed in close consultation with Emmi to meet the highest demands of the food industry. Particular attention was paid to maintaining the previous appearance of the cup while optimizing recyclability.

Operate the machine intuitively with the new Axos control system

Experience intuitive machine operation with the new Axos 9 control. At Fakuma, we are bringing Axos 9 to the machines of the Elion and Elios series. Call up the full performance potential of your Netstal machine. The integration of Smart Operation makes machine operation in the production environment fast, safe and extremely effective. Smart Operation is still available as a paid option in Axos 9.

Further packaging application with Netstal in Hall A3

Don’t miss a detour to Hall A3 either. A fully electric Elion 2200 awaits you, which we will present at our Turkish mold partner Ceylan. There, 150 g margarine trays with IML decoration are produced in 4 cavities. The cycle time is 3.8 seconds with a precise shot weight of 42 g. The IML system used, which includes side removal, camera control and packaging unit, comes from Eurasia Robotic in Turkey. Stop by and see this turnkey production line live at the Ceylan booth in Hall A3, Booth A3-3105.

Plan your trip to Fakuma and schedule an appointment with us:

Introducing: Our new brand identity

As of today, Netstal has a new brand identity. The values of leading, reliable and value-creating form the core of our tradition-rich brand. In doing so, one mission is our top priority: We want to work with you to increase your production efficiency and maximize your value creation. With Netstal, you get not only leading injection molding technology of the highest Swiss quality, but also a reliable partnership at eye level.

You can find out more here here

With a contemporary corporate design, we are visually communicating this positioning to the outside world. You have probably already noticed: The heart of the new brand identity is the graphically revised company logo. In the modernization process, we have been careful to respect our tradition. The familiar diamond shape, which has been opened up at the sides and forms a harmonious frame for the lettering, remains clearly recognizable. In a figurative sense, this also says that we are opening ourselves up to new opportunities and challenges. These include topics such as digitalization and sustainability, as well as the conscious use of the valuable material plastic. At the same time, we remain true to our core competence, the injection molding machine.

All technical data available online

From now on you can get information about our products and services here on our new website. A highlight is certainly new download center, which you can reach here:

Here we offer you a clear overview of all current series and their technical data. With practical filters you can limit the selection according to application area, drive technology, shot weight and column distance. In the English language version, the data sheets are available for download with either metric or imperial units of measurement. A note for you: The data sheets also contain a download link to the foundation plan.

New series coating for injection molding machines

With the change to the Axos 9 control generation, we are also applying our new design to the current machine portfolio. The dominant colors for non-medical machines are dark blue and white. Three-dimensional logos in chrome steel look emphasize the high quality of Netstal machines. Please feel free to visit our product pages for more views.

Visit us at Fakuma

Trade shows are and remain particularly important events for us. Nowhere else can we share our enthusiasm for injection molding with so many customers in such a short time. For these important personal encounters, we have created the best setting with our new and sustainable trade show concept. The booth, which is divided into two areas, impresses with its simple naturalness and modern spaciousness. In the front area, the focus is on the running machine exhibit for sustainable thin-wall packaging. The catering area has been spatially demarcated to allow for consultation meetings in as quiet an atmosphere as possible. We cordially invite you to visit us in Friedrichshafen. You will find us at our new regular place in hall B3 at booth B3-3119.

For more info on our trade show appearance, click here: Fakuma 2023

We hope that you will be as enthusiastic as we are about our new appearance. If you have any questions about this or any other topic, please do not hesitate to contact us. Please do not hesitate to contact us.

.png)