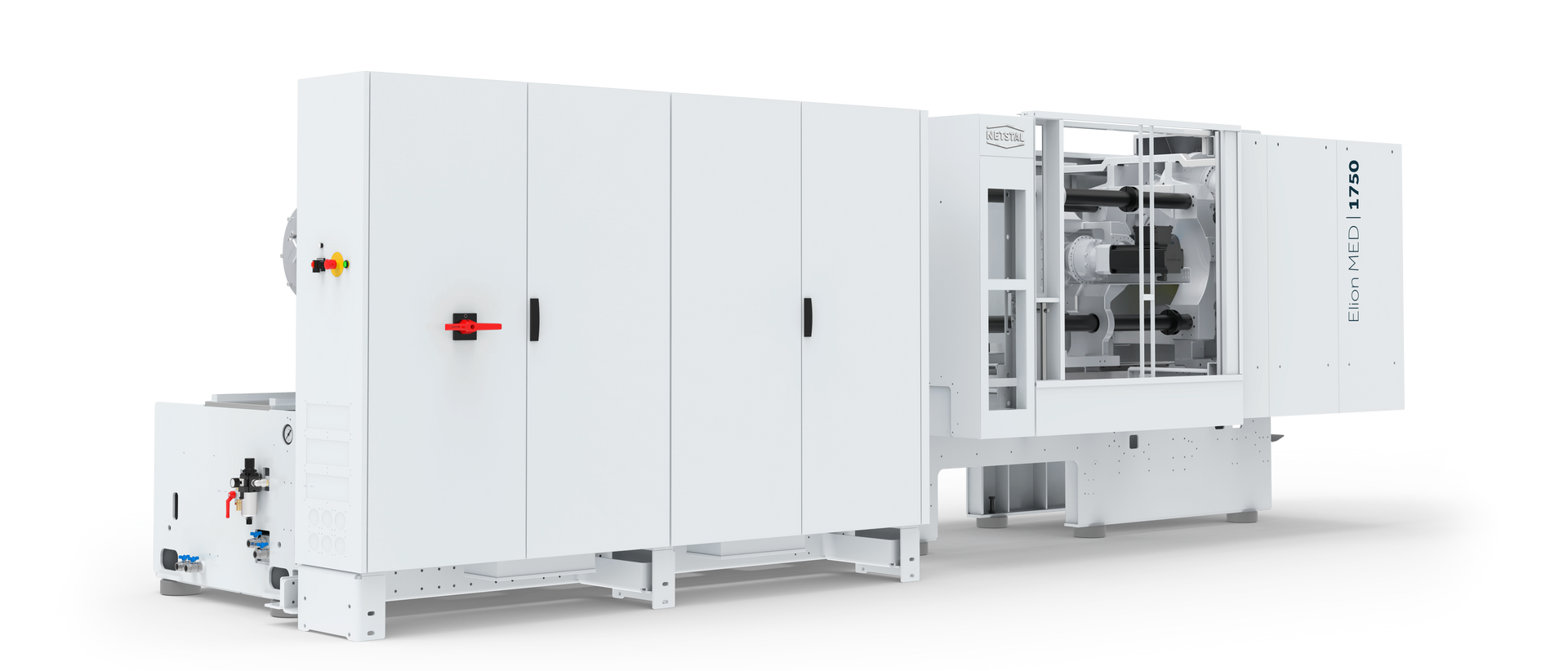

The all-electric injection molding machine

for medical technology applications

of the highest order

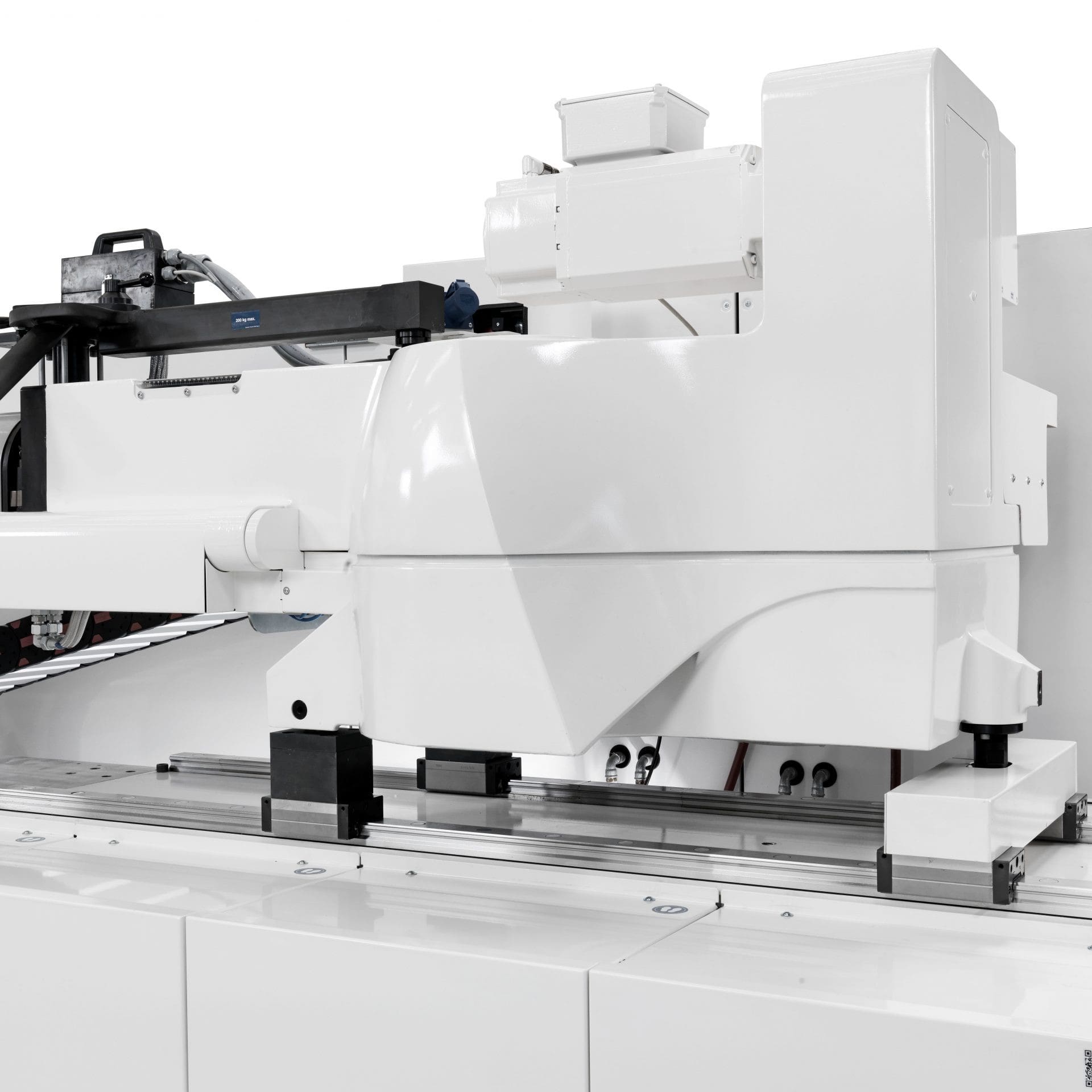

Consistent cleanroom suitability, high process capability and elevated injection dynamics are what make the custom-made Elion series injection molding machines with MED-Kit the most widely used core element of complex production lines for disposable medical items such as pipettes, petri dishes and blood collection tubes as well as other plastic medical technology parts, such as insulin pens and numerous other items.

Highlights

- Clamping force range: 800 – 2800 kN

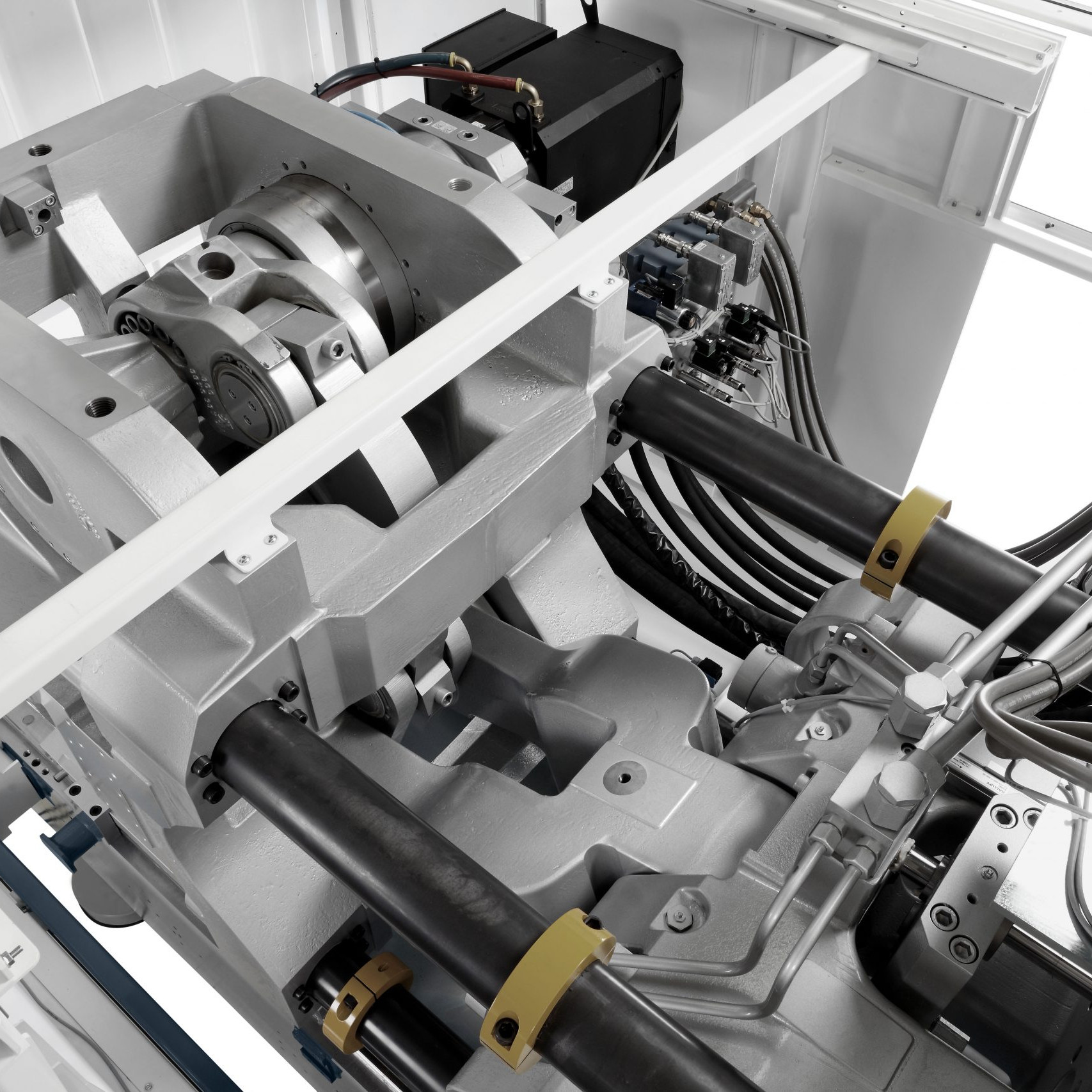

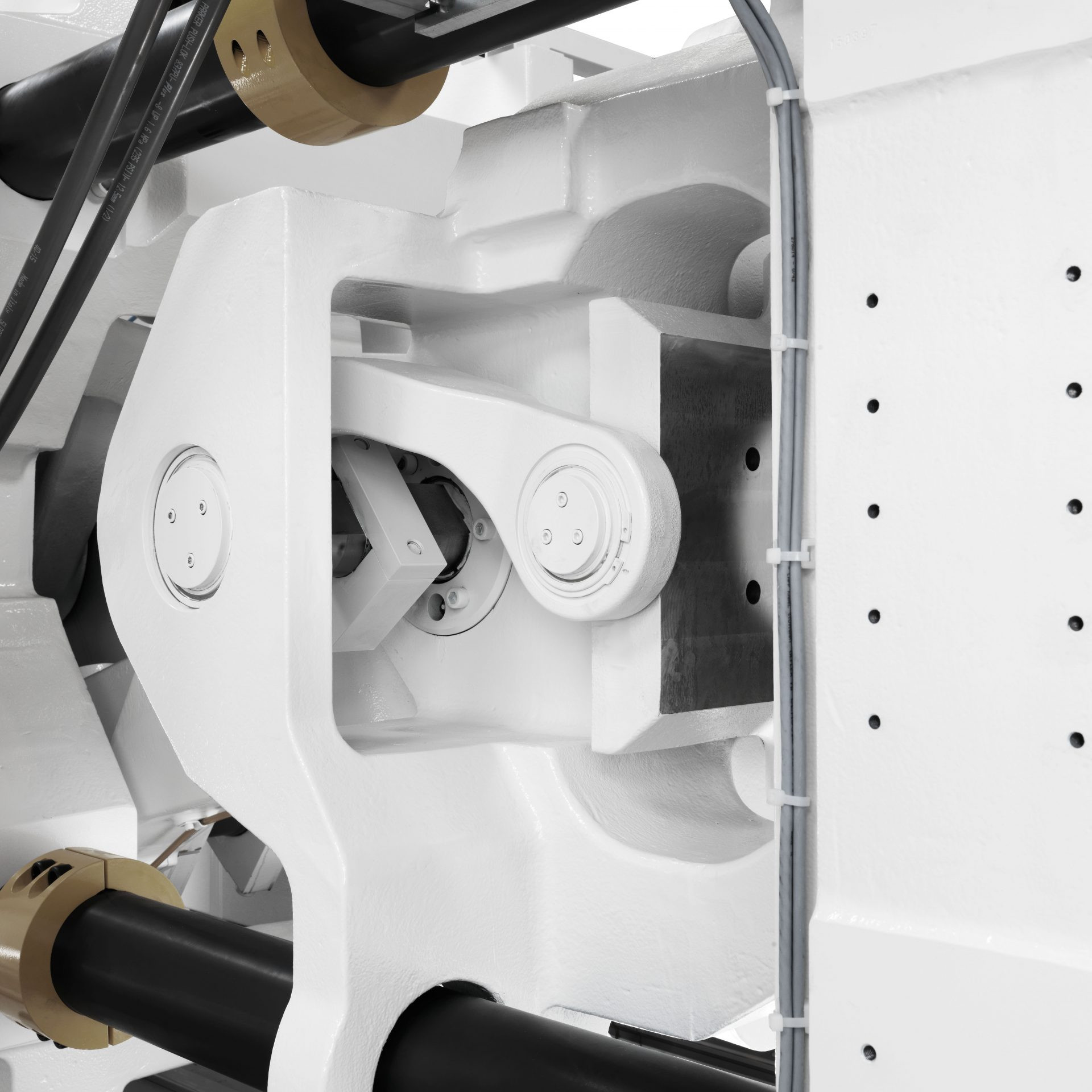

- Electric clamping unit for the fastest cycle times

- All-electric injection unit with integrated force measurement for maximum shot-to-shot consistency and a stable part weight

- Freely programmable Axos controller for optimum flexibility and user-friendliness

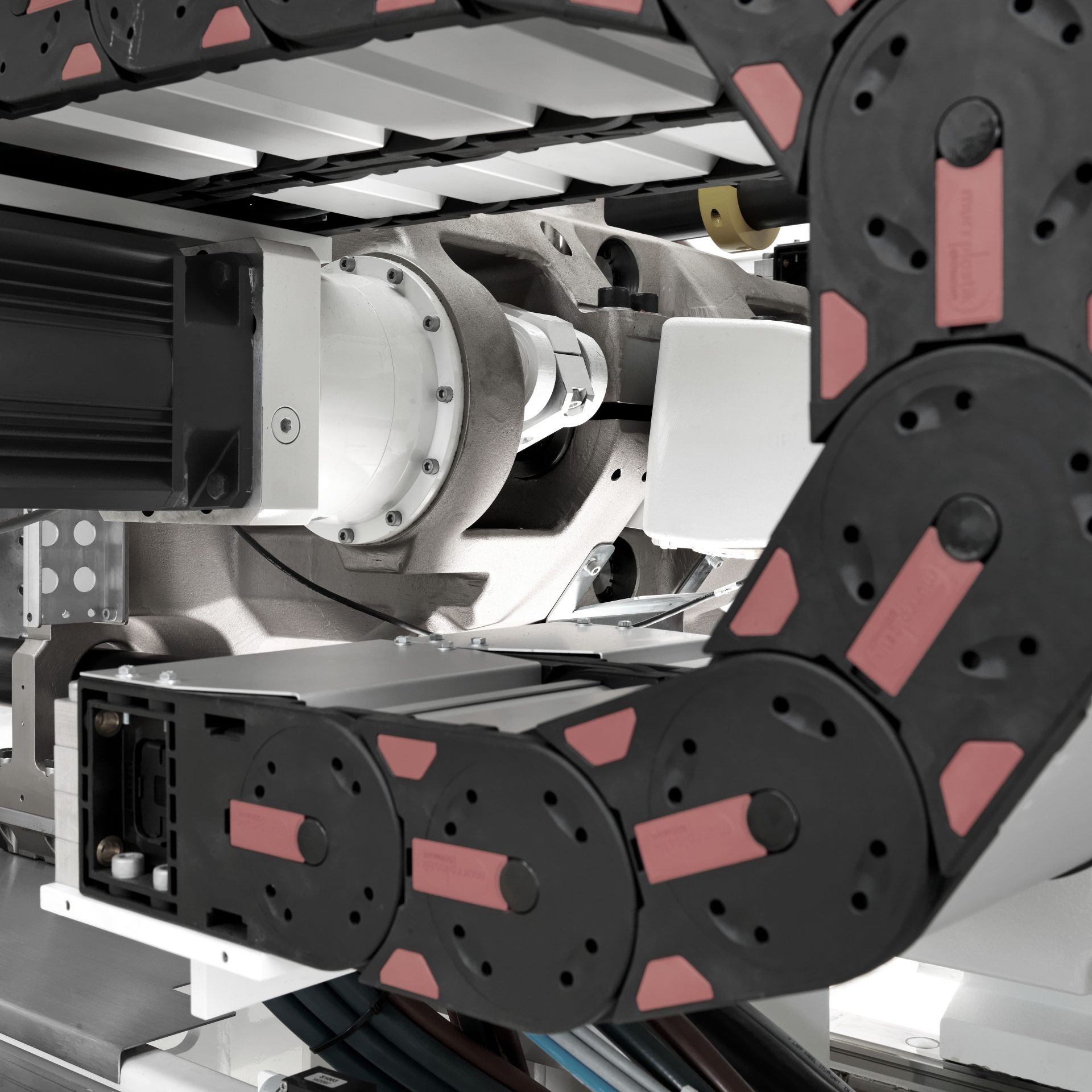

- Optimal energy efficiency due to the recuperation of kinetic energy

- Maximum reliability and system availability

- Smart Operation: Reliable embedding of handling specifications within the machine control system

Your benefits

Precision with system

Netstal has long been synonymous with consistent high-speed applications offering high precision and repeatability within a very narrow tolerance range. Thanks to our outstanding RFC injection control, you benefit from the superlative efficiency of the system as a whole, fewer rejects and a higher level of availability.

Effectively reduce energy consumption

We help you save electricity. Featuring energy recuperation from the clamping unit and adaptive system pressure reduction, the Elion is one of the most energy-efficient machines on the market. You save energy costs and simultaneously reduce your company’s ecological footprint.

Reliably plan productivity

The Elion is designed for continuous operation at maximum capacity. That means reliable manufacturing around the clock in the shortest of cycle times. Our successful medical technology customers regularly confirm that their Netstal machines still deliver the same powerful performance levels even after years of operation.

Sustainably increase availability

Our recipe to successfully increase your system availability: Reliable technology that manufactures at maximum speed with peak precision. In the unlikely event of a problem, you can always fall back on our global service network. Being localized, we can provide support either on-site or online.

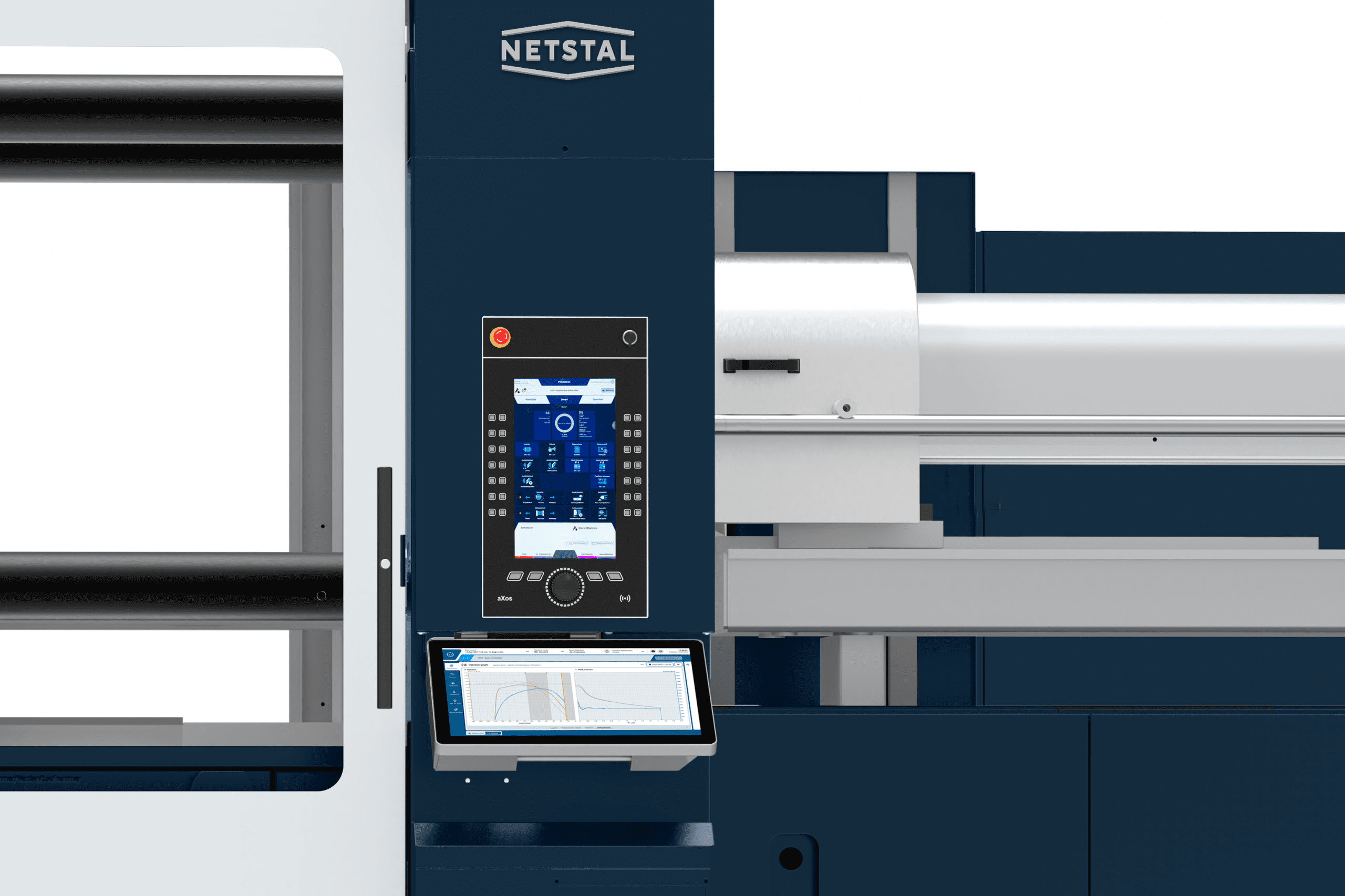

Axos controller

The newly developed Axos 9 controller allows you to get the most out of your Netstal machine.

We developed the controller to meet the increasingly complex requirements of contemporary and future applications. Numerous innovative functions support straightforward, fast and faultfree operation within the production environment.

Need-based operation provides an optimal and settingspecific user experience for operators within the product environment as well as in application programing.

Thanks to the advanced hardware combination and new temperature control, we achieve the highest quality in terms of production parts as well as a concurrent reduction in energy.

The integrated Four-key Smart Operation control panel enables simple and safe machine control within the production environment. Operating errors are reliably avoided. Smart Operation lastingly increases the overall equipment efficiency of your injection molding production.

Applications

Digital solutions

Netstal eService

Maintain peak production efficiency with our free eService. All machine specific documentation is provided here. Quickly identify and order the required spare parts with the 3D spare parts catalog. Use the ticketing system to directly request our support if required.

Netstal Remote Control

Access your machine controls at any time with Netstal Remote Control (NRC). Even complex application process settings can be adjusted remotely. Machine checks at change of shift can be carried out from the office to save the walk through the machine park. Use the collaborative potential to make internal technical assistance available oncall 24/7 and across all locations to support other plants.

Standardized data exchange

The Euromap 77 standard specifies the interface between injection molding machines and the overriding production control system. Systems (MES, ERP, QM, etc.). The basis for Euromap 77 and other Euromap interfaces for integrating periphery systems, such as Euromap 82.1 for temperature control devices and Euromap 82.2 for hot runner control devices, is OPC UA, one of the most widely used Industry 4.0 protocols. OPC UA enables standardized, manufacturerindependent and efficient data exchange between machines, devices and other systems within the industrial environment.