At the NPE you will experience high-performance injection molding in its purest form at Netstal. Together with our system partners and customer Alltrista®, we will be presenting the world's most powerful production system for lightweight beverage closures. The key data are impressive: 26mm water closures, 128 cavities, 1.9 second cycle time, 25 % material savings. Read the story to find out how this project came about.

At Alltrista, the production of 26mm water closures is running at full speed on two production lines. Anyone familiar with the subject quickly realizes that a very special application is in use here. You rub your eyes in amazement: is this a mold with 128 cavities that is moved here with a cycle time of 1.9 seconds? Can that be true? Yes, it is: Alltrista is the first company in the world to produce over 3 billion closures with a program like this. To be precise: 3.1 billion caps. We can announce this with a broad chest: We are proud to be part of this success story with our leading injection molding technology.

But let’s hear from our customer first.

“We wanted to be the first manufacturer to operate a system with 128 cavities in less than 2 seconds. With Netstal, z-moulds and Intravis, we have found the best system partners for this project. Each company is a leader in its field and the combination is unbeatable from our point of view. We simply thought: if this is to work, we need exactly these three partners. With the first two 128-cavity systems, we are now producing more efficiently than ever before, can deliver at any time and delight our customers. This has given us an enormous competitive advantage.”

Christopher Navratil, CTO at Alltrista’s parent company

Innovative mold-machine combination pushes physical boundaries

Let’s go into a little more detail. Water closures of the 26 mm type are produced for still water that is filled into PET bottles. Thanks to an innovative design, z-moulds was able to make its mold as small and light as a 96-cavity mold. This results in decisive advantages for the user. Compared to previous 128-cavity molds, the mold fits into a machine with a smaller tie bar distance. The compact design of the mold also means that less mass needs to be moved. An important prerequisite for the fastest possible cycle times. Consequently, running 128 cavities with a cycle time of less than 2 seconds is a world first. At Alltrista, the lines run at around 1.9 seconds. Occasionally it is also 1.85 seconds. The complete production system also requires very little floor space. Each line produces 1.55 billion closures per year on around 50 square meters. More output per square meter of production area is currently not possible.

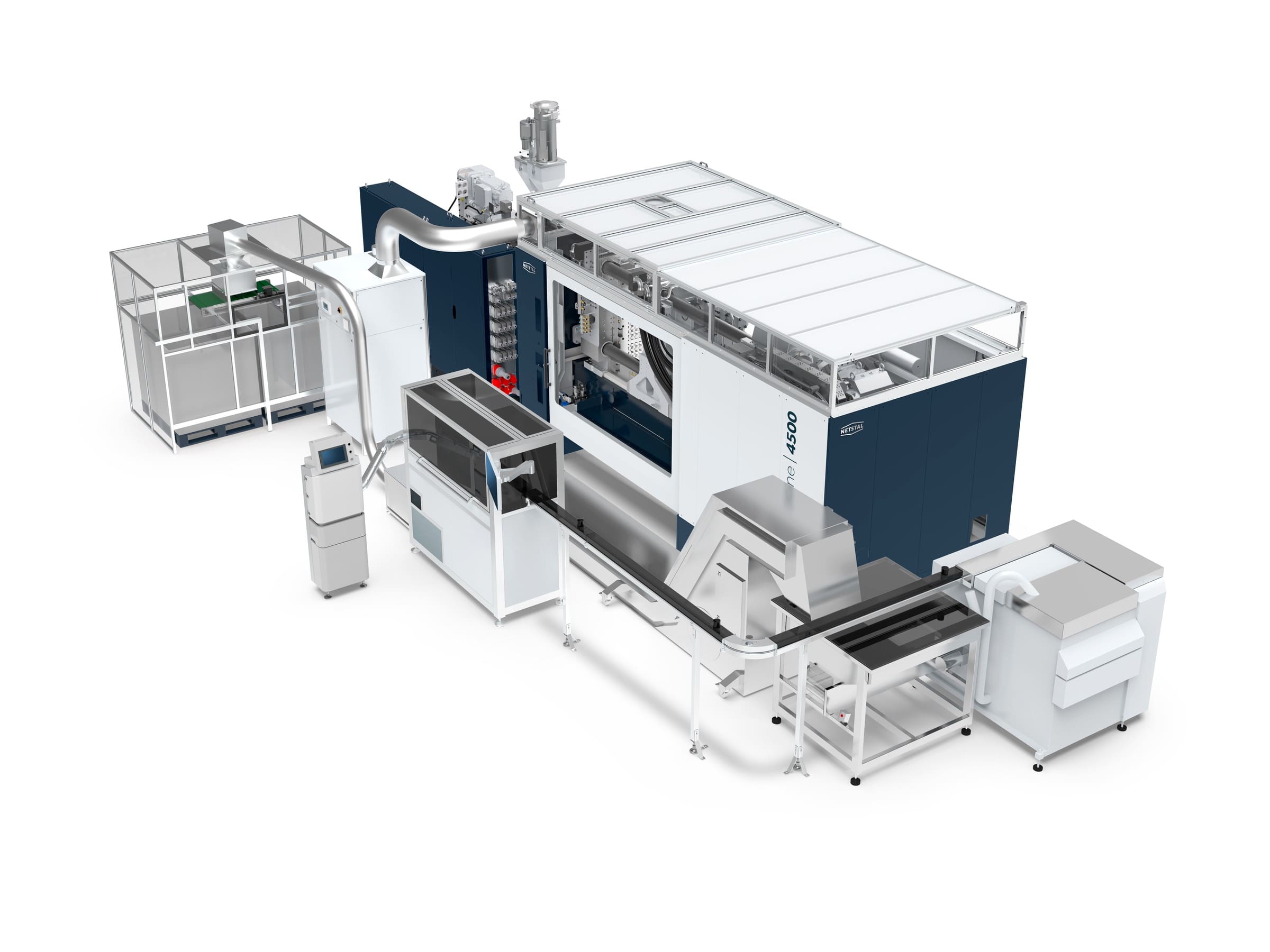

Maximum productivity in a small space: At around 50 square meters, the Alltrista production system only requires a small footprint

Significant energy savings and 25% less plastic

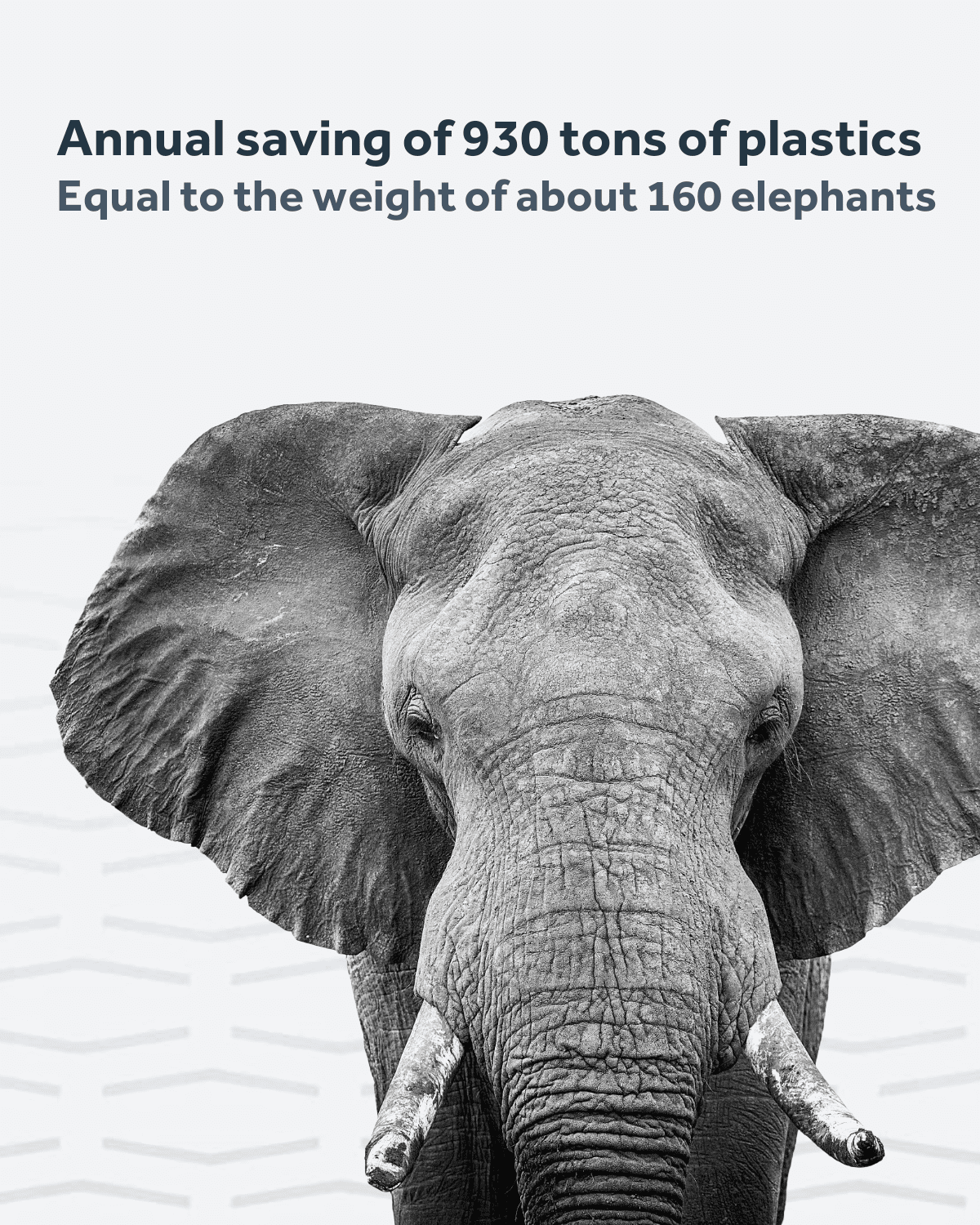

More output is a great thing. Add to that savings on materials and electricity and you have efficiency at its peak. Comparative measurements have shown that the Elios 4500 with 128 cavities consumes around 12% less electricity than comparable machines from the competition. However, these were equipped with only 96 cavities. In addition, the application engineers at Alltrista were able to make the closures 25% lighter and therefore much more sustainable without compromising their function. Based on the full programm productivity of 3.1 billion closures per year, Alltrista saves over 930,000 kg of material. This corresponds to the weight of approximately 160 adult African elephants.

Intravis high-speed downstream quality control

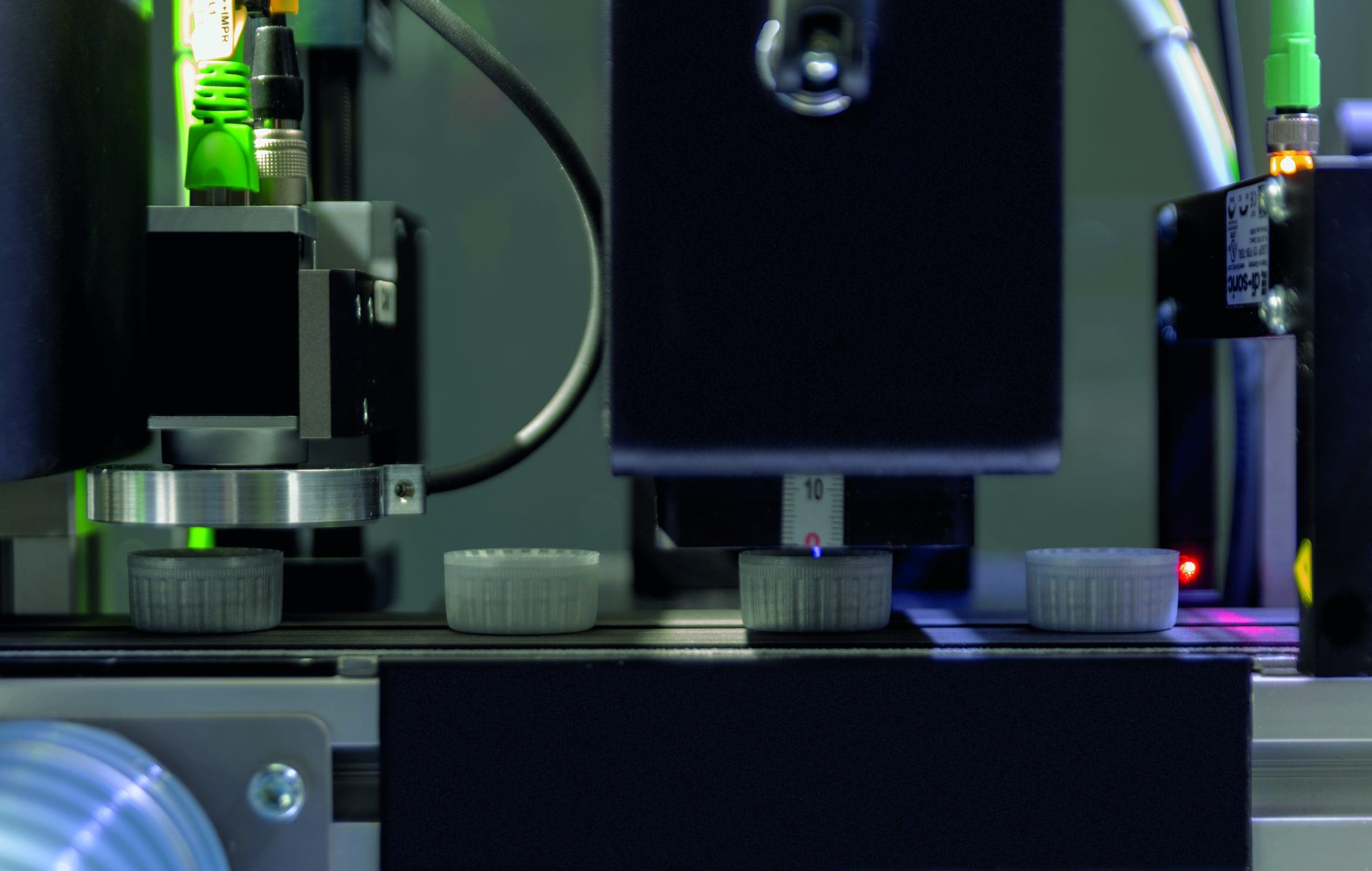

However, the enormous number of caps is not yet ready for dispatch immediately after demolding. Before they can be filled into octabins, the closures pass through the downstream equipment of our system partner Intravis. The CapWatcher Q-Line carries out a comprehensive 360° full inspection of the closures. Today’s computing power makes it possible: up to 80 closures per second are checked for more than 40 quality criteria with an accuracy in the hundredth of a millimeter range. The cavity-related inspection is carried out with up to nine high-resolution cameras. An enormous amount of data that is processed in real time. The high performance gives Alltrista the certainty at all times that the closures are flawless immediately after production and that customers are only supplied with good parts.

A look inside the CapWatcher Q-Line. The system uses 9 high-resolution cameras to check up to 80 caps per second for more than 40 quality features

Alltrista: Innovative contract manufacturer from South Carolina

All in all, the Alltrista production system for 26 mm closures is the new benchmark in terms of speed, productivity, efficiency and sustainability. Two identical system solutions for closure production are currently in production at Alltrista. Alltrista Plastics LLC specializes in innovative, high-volume precision manufacturing. From rigid packaging and custom molded solutions to assembly, filling and kitting, Alltrista supports customers in the medical, healthcare and consumer goods industries with a wide range of products and services. The company’s ability to assemble strong teams on a project-by-project basis allows it to be flexible on even the most challenging orders.

Christopher Navratil confirms: “This closure application is proof of our innovative strength and our unbridled desire to keep pushing the technological boundaries. We are proud that, together with the experts from Netstal, z-moulds and Intravis, we were able to increase productivity by at least 30 percent in this project. For us, this is a prime example of how companies from the USA can work successfully with partners from Germany, Austria and Switzerland.”

Alltrista attaches great importance to the continuous improvement of its own sustainability. The company was audited by Ecovadis in 2023 and received the silver medal for its sustainability performance to date. Alltrista ranks in the 88th percentile of all companies assessed by Ecovadis and among the top 7% of peer companies.

Witness the Alltrista production system live at the NPE in Orlando

As mentioned at the beginning, we will be presenting an identical production system for 26 mm closures at our NPE stand. Alltrista will have its own staff on our booth to provide information from the customer’s perspective. For detailed information on all the company’s services, we also recommend a visit to booth S22065 in the South Hall, where Alltrista will be showcasing its full range of contract manufacturing and injection molding products and services.

Visit our NPE exhibitor profile and plan your visit:

CAP-Line

At the NPE you will see a Netstal machine labeled CAP-Line for the first time.

With the CAP-Line, we offer specifically pre-configured injection molding machines for closure applications. The CAP-Line 4500 on our stand is based on the high-performance Elios platform and is equipped with various features for the efficient production of beverage closures.

The CAP-Line 4500’s all-electric toggle-type closing unit with a drying time of 1.4 seconds enables cycle times of less than 2 seconds. Thanks to the optimized barrier screw, we can use a smaller injection unit. The new screw design ensures a higher plasticizing performance and a better degree of homogenization. Further options are available for individual optimizations, such as our four-button Smart Operation or the adaptive system pressure reduction, with which you can achieve additional energy savings.

With the new concept for the CAP-Line, we are aligning our portfolio even more closely with our customers’ applications. As a closure manufacturer, you benefit from a system that is individually tailored to your application. However, pre-configuration speeds up the consultation and quotation process so that delivery times for the machine are as short as possible.