Exhibit: Thin-wall packaging

Optimized for recycling: Transparent IML thin-wall cup made of PET

- 450 ml cup with in-mold labeling

- PET cup and label

- Cup weight: 15 g

- Mold: 2 cavities

- Cycle time: 4 s

- Injection molding machine: Elion 3200

- Clamping unit: Electric

- Injection unit: Hybrid

Exhibit partners

- Mold: StackTeck

- Automation: StackTeck

- Vision control: IMD Vista

- Label: MCC Verstraete

- Resin: Eastman

- Material handling: Piovan

Exhibit: Beverage closures

26 mm caps for still water in PET bottles

- 26 mm cap with tamper-evident closure

- Mold: 128 cavities

- Cycle time: 1.9 s

- Injection molding machine: CAP-Line 4500

- Clamping unit: Electric

- Injection unit: Hybrid

Exhibit partners

- Mold: z-moulds

- Downstream equipment and vision control system: Intravis

- Material handling: Piovan

- Material: Ineos

- Quality control of the tamper evident band: PackSys Global

- Metal separator: Sesotec

Customer

- We are hosting our valued customer Alltrista, who will be presenting this high-performance closure manufacturing solution from a customer perspective and will be available to answer any further questions about their contract manufacturing offering

Further topics on our stand

Life Cycle Services

- Used machine program

- Machine overhauls

- Services

- Upgrades

- Process optimizations

- Training courses

Digitalization and connectivity

- eService

- Netstal Remote Control

- Experts from our digitalization partner bfa solutions are available to answer your questions and provide solutions for Industry 4.0 and IoT

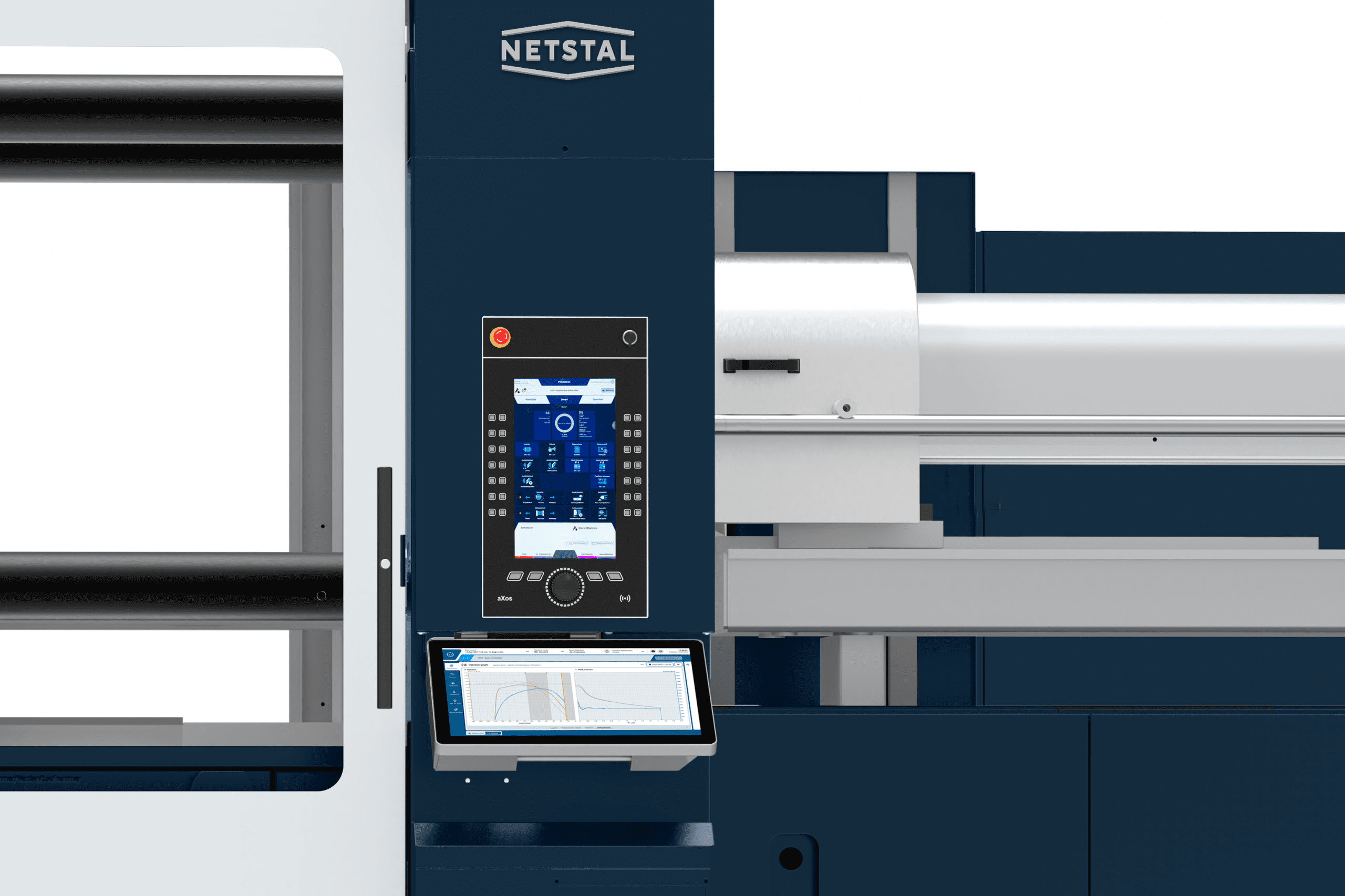

Axos controller

The newly developed Axos 9 controller allows you to get the most out of your Netstal machine.

We developed the controller to meet the increasingly complex requirements of contemporary and future applications. Numerous innovative functions support straightforward, fast and faultfree operation within the production environment.

Need-based operation provides an optimal and settingspecific user experience for operators within the product environment as well as in application programing.

Thanks to the advanced hardware combination and new temperature control, we achieve the highest quality in terms of production parts as well as a concurrent reduction in energy.

The integrated Four-key Smart Operation control panel enables simple and safe machine control within the production environment. Operating errors are reliably avoided. Smart Operation lastingly increases the overall equipment efficiency of your injection molding production.