We think from our customers' perspective

As the world's leading Swiss manufacturer of injection molding machines and system solutions for plastics processing, Netstal Maschinen AG is also intensively engaged with digitalization and sustainability. In this interview, Renzo Davatz explains what this means for the further development of technology and what role leadership plays in volatile times for the future of the company and Switzerland as a manufacturing location.

Mr. Davatz, how has your core business, the manufacture of injection molding machines for plastics, changed in recent years?

The most significant change is probably the pressure from Chinese manufacturers, who have caught up technologically and are pushing into Western markets with highly aggressive pricing. This combination of increasing technical competitiveness and enormous price aggressiveness is also changing the business for Western injection molding machine manufacturers.

Which target markets are particularly important to you?

Europe has historically been an important market for us. We are now well established there. We expect the greatest growth to come from the US, which is a very exciting market. At the same time, we are also active in Asia. For the past two to three years, we have also been very successful in India, which is also developing into an exciting market for us.

The packaging of food and the manufacture of medical consumables are fundamental aspects of our everyday lives. Does that mean we have a special responsibility?

The greatest responsibility that I, or we, feel is to live up to the Netstal brand promise. Netstal is known for maximum performance and optimum production efficiency. We want to live up to this promise not only with performance and quality at delivery or in the first year of operation, but throughout the entire life cycle of a machine. With comprehensive service for spare parts, retrofits, and optimizations, we want to maintain high production efficiency and availability of the systems throughout their entire service life. Of course, there are specific requirements in the food and medical sectors regarding cleanliness, traceability, and documentation, to which we have always been committed.

Are there any new trends in plastics processing that will shape the coming years?

In the areas of application in which we operate, there are not as many new plastic materials as there are in the automotive industry, for example. However, there is a trend towards using PET, the material used to make PET bottles, for other applications as well. For example, caps, which have traditionally been made from HDPE, are now also to be made from PET, even though this poses a major technical challenge. This would further facilitate the recycling of PET bottles, for which a closed loop has already been established in Switzerland and Germany. There are also attempts to produce thin-walled and food packaging from PET. In addition, there are bio-based plastics, which have not yet become widely accepted because they are too expensive in large quantities. Technically, this already works, but it does not yet make economic sense.

"There are product managers, salespeople, and application engineers for each area. And they think strictly within their field of application and work on optimizations for these applications."

To what extent are new developments determined by digitalization and sustainability?

Whereas in the past it was all about the physical product, namely the machine, today it is increasingly about being able to offer customers an integrated, networked, and therefore autonomous production cell. This should be as easy to operate as possible, deliver high output, and offer correspondingly large process windows. When it comes to sustainability, two aspects are now crucial. The machine itself should consume less and less energy. This means that hydraulic axes are increasingly being replaced by electric axes. Secondly, it is important that the machines can process materials such as rPET, which means recycled PET, without any problems.

So you always have to think from the perspective of customers who want to manufacture or package their products even better or more efficiently?

This customer-oriented approach is very important to us. We have four application units: PET preforms, which are preforms for subsequent PET bottles, closures, medical technology applications, and thin-walled packaging, for example, for ice cream, butter, or margarine. There are product managers, sales representatives, and application engineers for each area. They think strictly within their field of application and work on optimizations for these applications.

What sets Netstal apart from its international competitors?

We are very focused on our four areas of application and do nothing else. If you ask me about our USP, I would say that Netstal stands for exceptional production efficiency. Our machines may not be the cheapest to purchase, but they enable you to manufacture your product at the lowest possible cost.

What does leadership mean in the face of global crises, regional sanctions, or regulations?

In my opinion, all the volatility and uncertainty make the job more exciting than ever. I believe the challenge is that a good leader must be able to set a direction even when not all the answers are available. It is important to communicate honestly about what is known and what is not. And to set clear priorities that help the team remain capable of acting despite uncertainties. Good leadership in volatile times means having inner stability while everything around you is in flux.

What makes Netstal stand out as an employer?

I would highlight two points. First, despite, or perhaps even because of, a very challenging environment in the industry, we have a team that has developed a special corporate culture and is enthusiastic about our customers and their products. A genuine Netstal spirit, if I may say so. The second point is our international environment. With a technologically sophisticated product and an export quota of 95 percent, the company can naturally offer exciting and very diverse careers as well as opportunities for further development. It has been exciting from the very beginning. I was able to experience this myself, as I started as an apprentice in this company.

The interview was conducted for the new issue of “20 CEOs. 20 OPINIONS” in Handelszeitung, published on December 24, 2025. We translated it to make it available for our international followers. Click on the following link to view the entire issue (German).

New: Adaptive system pressure reduction in PET applications

With the adaptive system pressure reduction function, users of the Elion and Elios series have already been achieving considerable energy savings since 2023. The option is now also available for PET-Line.

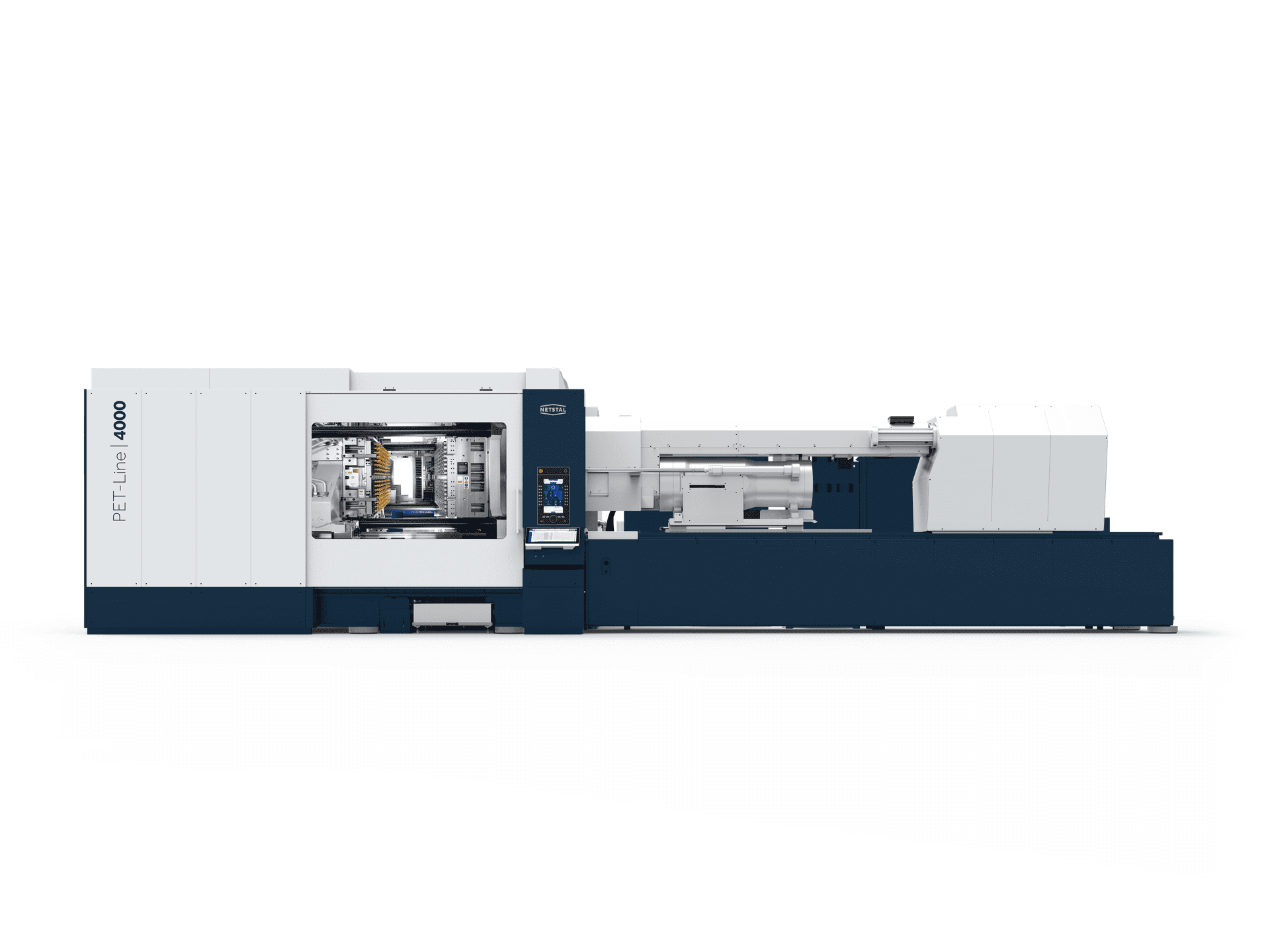

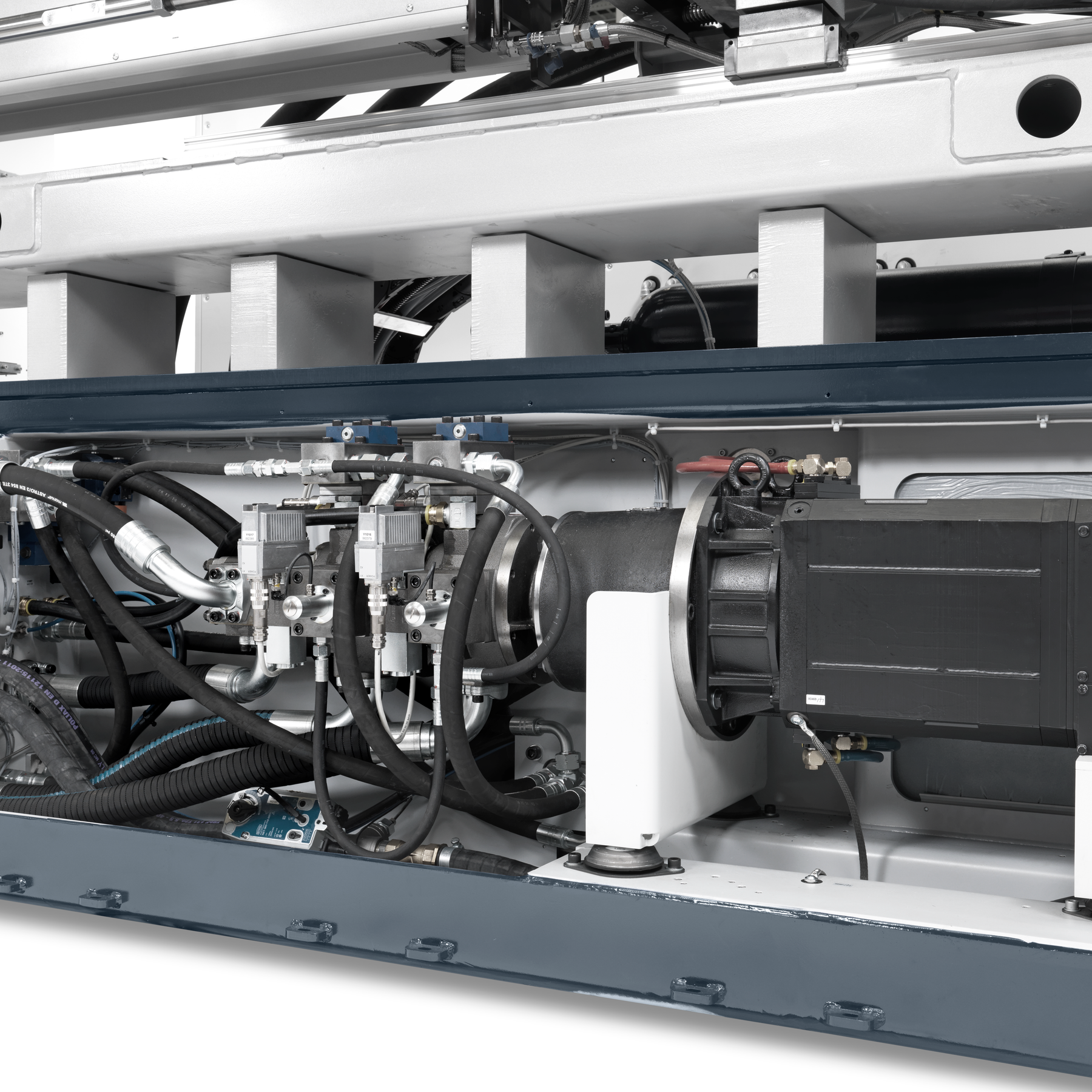

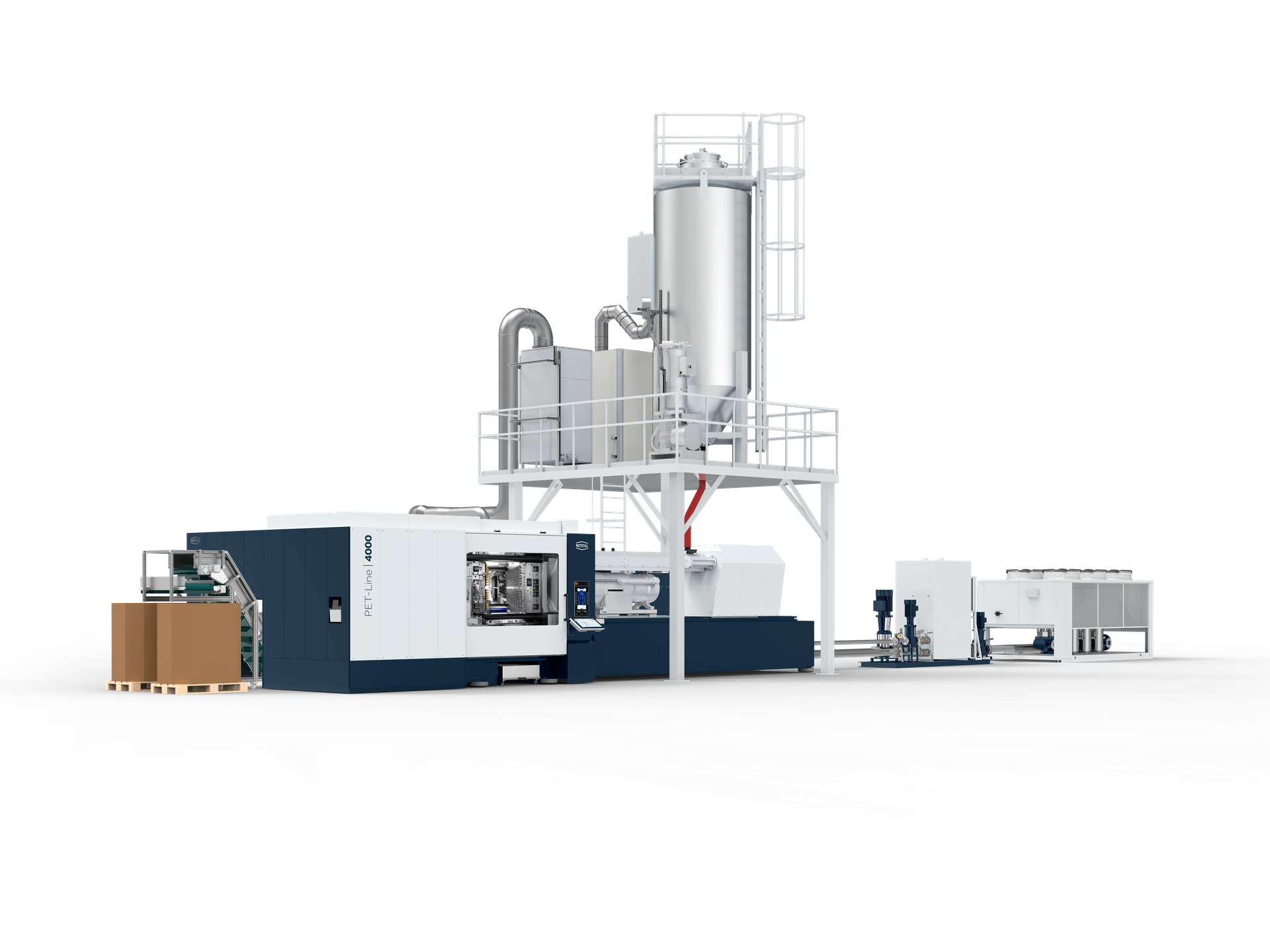

Since its market launch in 2020, the PET Line with side entry has been considered the most modern and energy-efficient preform injection molding system on the market. With the adaptive system pressure reduction, which is now also available for the PET-Line, Netstal is further increasing efficiency. With active system pressure reduction, the hydraulic pressure is lowered to the optimum point. Only as much pressure is generated as is required.

Please accept YouTube cookies to play this video. By accepting you will be accessing content from YouTube, a service provided by an external third party.

If you accept this notice, your choice will be saved and the page will refresh.

The video illustrates how adaptive system pressure reduction works.

Leading energy efficiency at maximum productivity

The potential is enormous: depending on the application profile, you can save five-figure energy costs per year with the system pressure reduction. The significantly reduced consumption also lowers the CO2 footprint of your entire production. Most importantly, the cycle time and injection performance are not affected. The PET-Line produces the same output and consistent quality with lower power consumption.

Find out more at drinktec

At our live exhibit at drinktec, we will be happy to advise you personally on adaptive system pressure reduction and the many other benefits of the PET-Line that will make your day-to-day production easier. At our stand, you can experience a PET-Line 4000 of the latest generation. It produces ultra-light 6.9 g preforms with a 25/22 neck thread. The visit is worthwhile, you will find us from September 15 – 19 at the Munich trade fair, Hall C6, Stand 361.

Fair information and appointments

Visit Netstal at drinktec 2025 and experience the next generation PET-Line

Efficient and resource-saving: Netstal will be presenting a new generation of PET-Line for the first time at drinktec (September 15–19, 2025, in Munich). With smart innovations, the system not only increases production efficiency but also improves user comfort.

At the Netstal booth in Hall C6, a PET Line 4000 is producing ultra-light 6.9 g preforms with 25/22 threads.

Commitment to sustainability: After drinktec, the preforms will not simply be disposed of, but returned to the PET recycling loop.

These highlights await you:

- Maximum performance potential: A 144-cavity mold from MHT with integrated self-cleaning function is used. The fast cycle time of 4.8 seconds produces around 108,000 preforms per hour. A 160-cavity option further increases the potential with a clamping force of 400 tons. The largest PET-Line 5000 is available for maximum output. With a clamping force of 500 tons, molds with up to 192 cavities can be used.

- Leading energy efficiency: The PET line uses kinetic energy recovery in the clamping unit and post-cooling station. With top ratings, the PET line stands out as one of the most energy-efficient PET systems on the market. A new feature is the optional system pressure reduction: It lowers the hydraulic pressure and keeps it at the optimum point. Depending on the application profile, additional annual energy costs in the five-digit range can be saved.

- Focus on the highest quality: The fully integrated Vision Control System checks the preforms in real time, detects possible process errors at an early stage, and documents everything automatically. With the new Quality Shot, random samples of a complete shot can also be taken at the touch of a button.

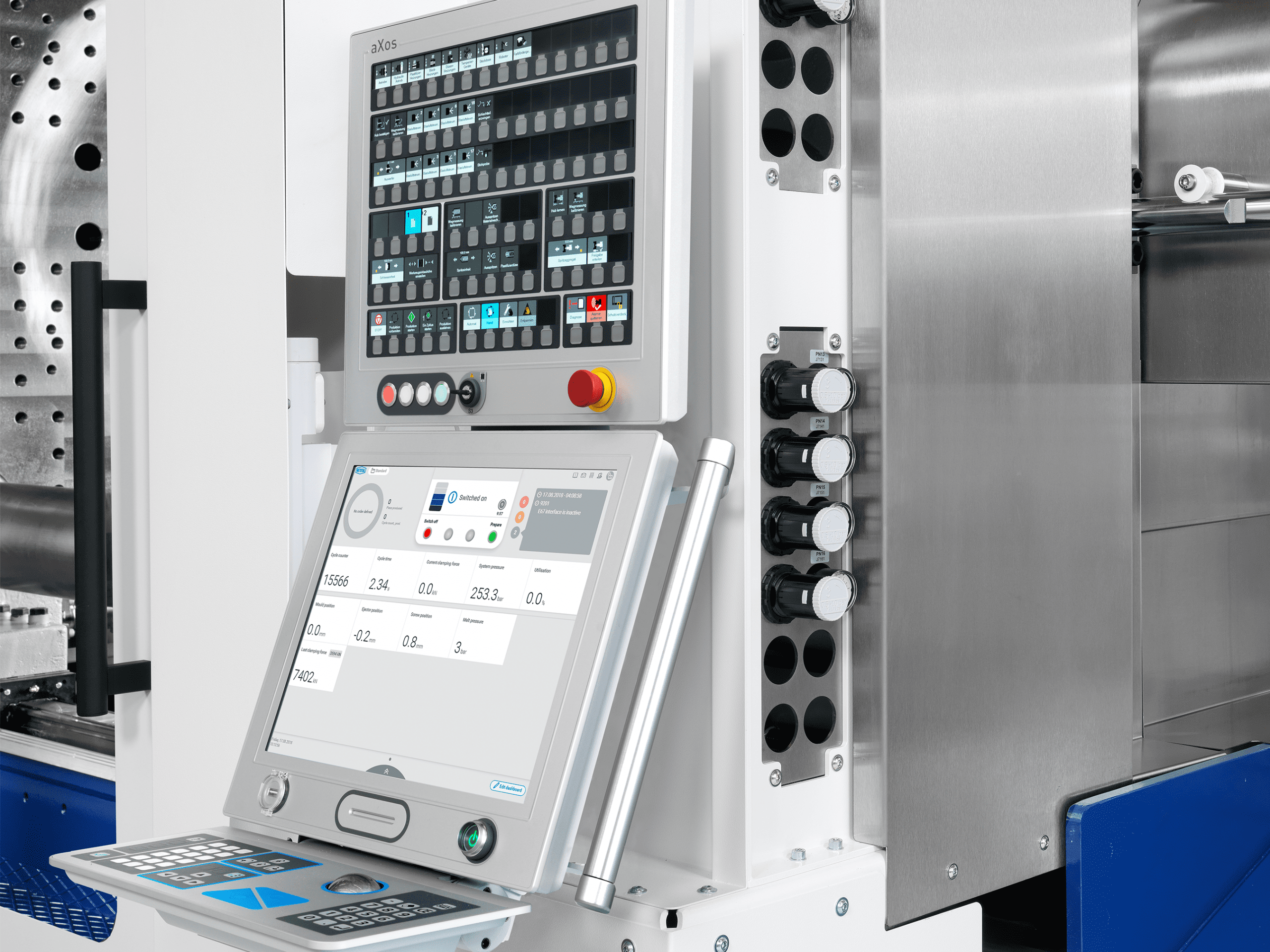

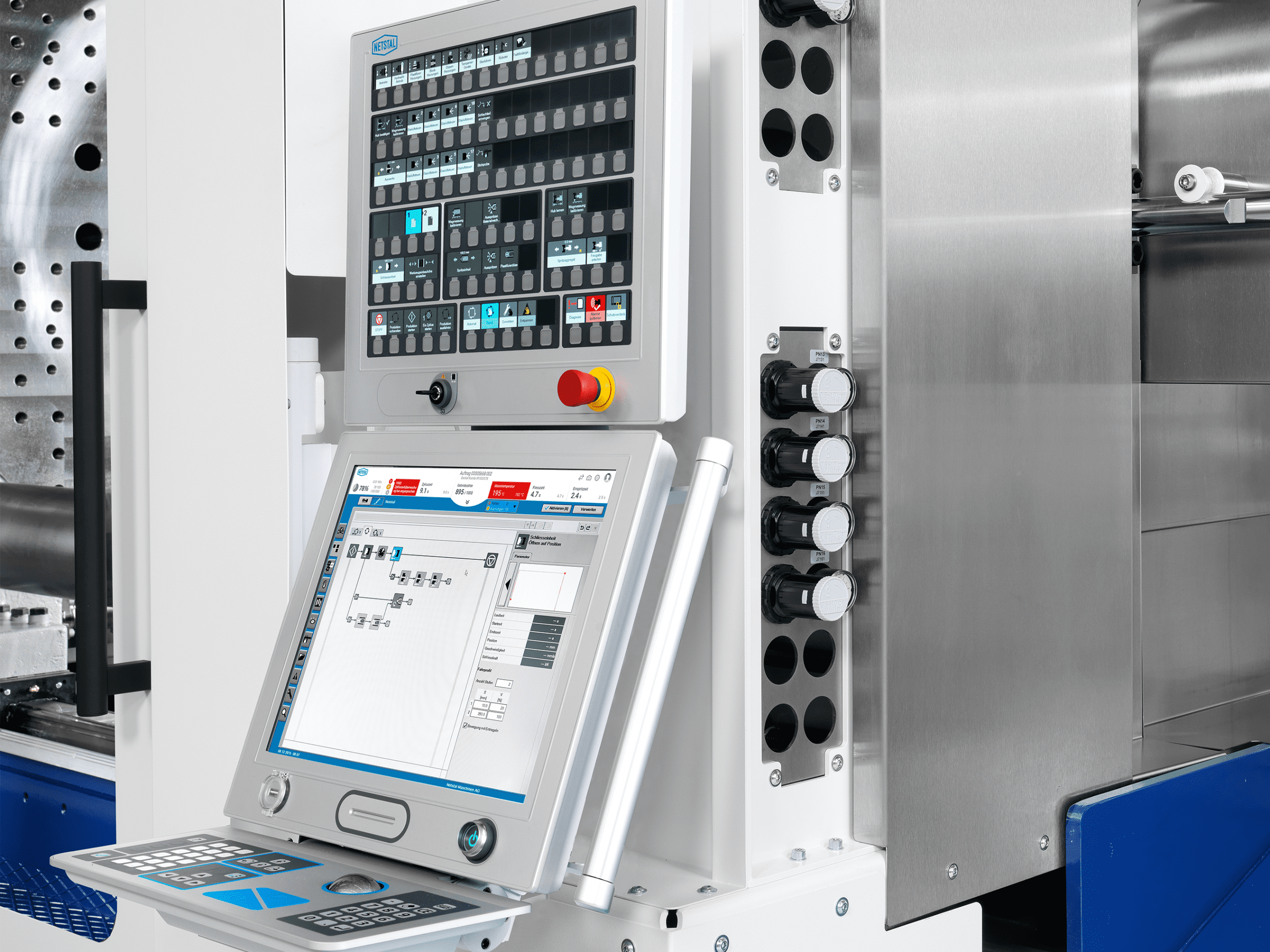

- Redesigned ease of use: The Smart Operation feature integrated into the Axos control system makes operation during shift work particularly safe and intuitive. With the new Task Quick Mold Change, even low-skilled personnel can now change molds quickly and safely. Tasks are graphically designed application aids that guide users step by step through more complex tasks. Additional tasks are already in the planning stage.

- Connectivity for maximum control: The PET-Line offers all modern interfaces based on OPC-UA for networking with central control systems and various peripheral components.

The PET-Line sets new standards in terms of performance, energy efficiency, quality assurance and user-friendliness. So it’s well worth a visit from September 15–19 at drinktec 2025, Hall C6, Stand 361.

Trade fair information and appointments

Next machine generation: Experience the new Elion MED at K 2025

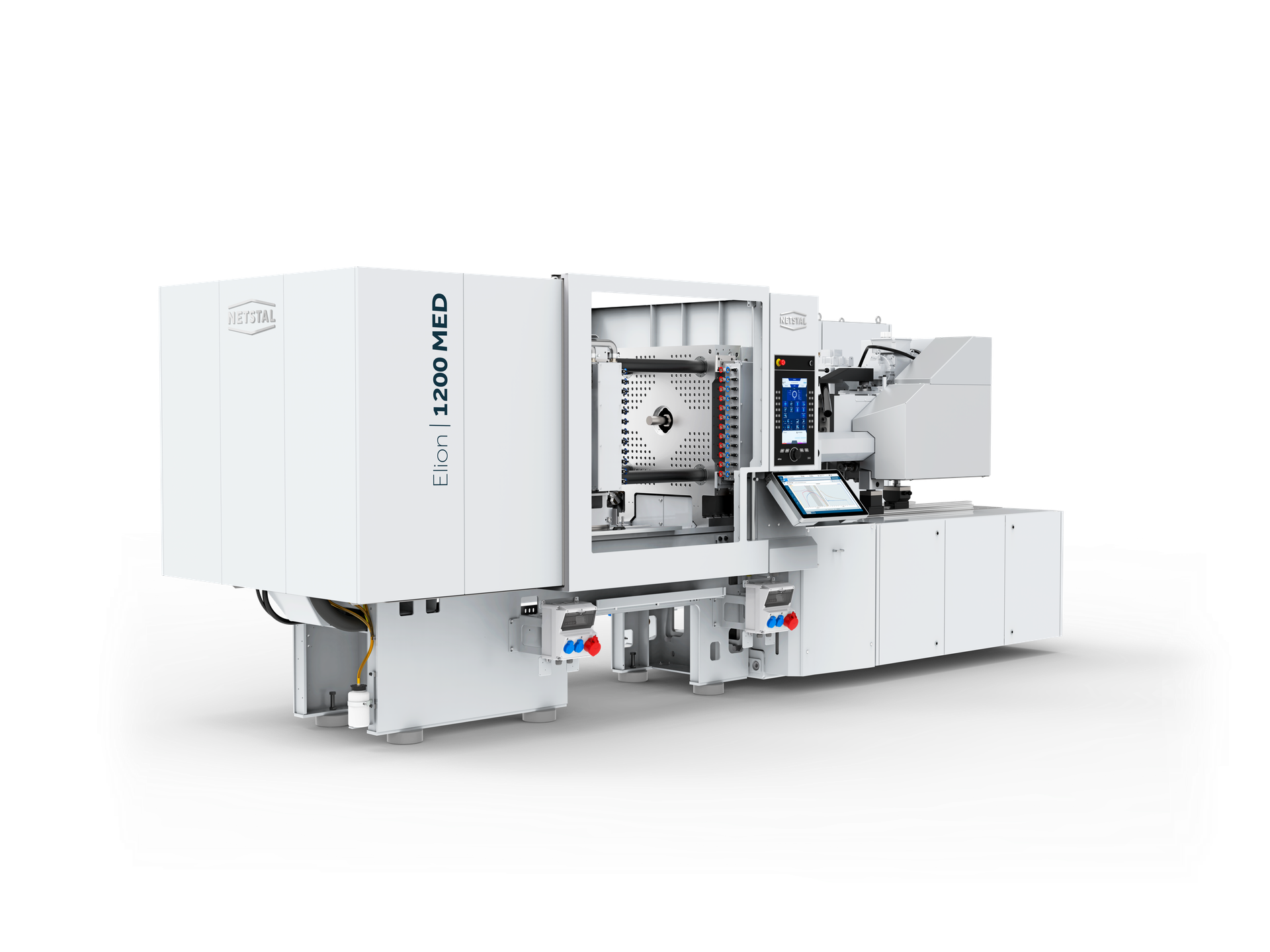

Do you manufacture medical technology parts from plastic and are you enthusiastic about innovative injection molding technology? Then you should plan a visit to Netstal at K 2025. In our booth D24 in hall 15, we will be presenting the latest generation of the Elion MED with a shortened design, optimized toggle lever geometry and a new injection gearbox. With the new Elion MED, you can produce on a smaller footprint with increased efficiency. We call this "the evolution of efficiency".

These highlights await you:

- High performance in a small space: We have consistently optimized all modules for a compact footprint. The result is a significantly shorter machine that offers outstanding performance and great flexibility for a wide range of applications with identical clamping force.

- Leading precision: High-precision sensors with an extremely high 2 kHz sampling rate enable unmatched precision and reproducibility. The newly revised quality monitoring system ensures seamless monitoring and assurance of production quality.

- Unmatched reliability: Netstal machines are particularly durable. With the new Elion, we have further developed proven concepts. The machine is extremely solidly engineered. This enables us to meet your high requirements so that you can produce continuously for many years without any loss of performance.

- Maximum efficiency: The servo drives we use offer you the best energy efficiency. With the newly designed servo-hydraulic direct drive for the aggregate movement and the application of the contact force, we have once again significantly increased the energy efficiency of the Elion.

- Clean room compatible: Thanks to fully encapsulated and water-cooled drive motors and hermetically sealed control cabinets, the new Elion operates with virtually no emissions. We have designed the entire machine with its new protective housing for optimal cleaning. The Elion MED can be used in clean rooms up to class 7 as standard. Higher clean room classes are also possible with additional equipment options.

- Open connectivity: The new Elion offers all modern interfaces based on OPC-UA for networking with central control systems and various peripheral components. Thanks to HTML 5 integration, even more complex system components can be easily integrated into the machine control system.

Live production at the Netstal booth:

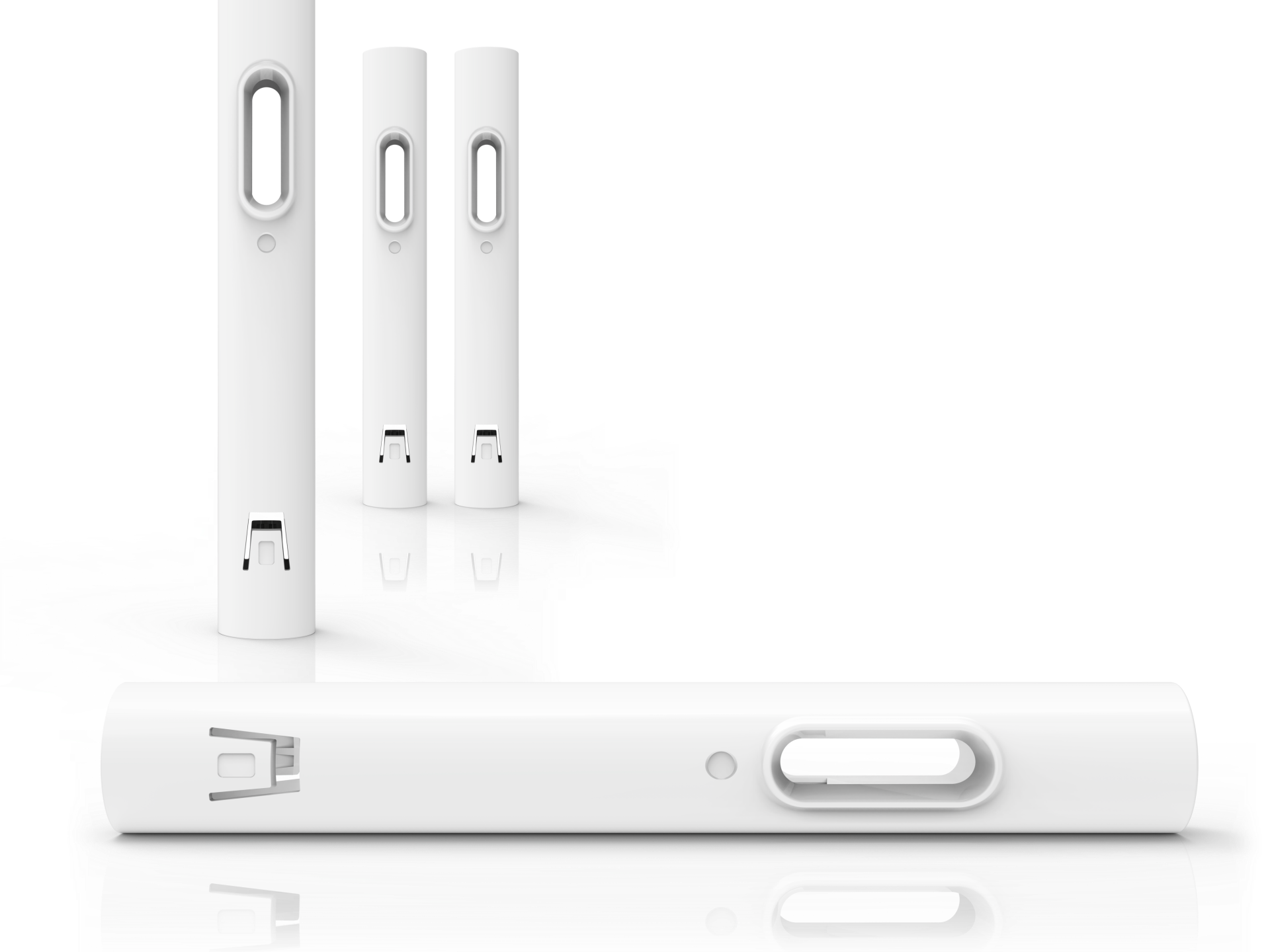

For the market launch, we will be demonstrating the new Elion MED in action at K 2025 in Hall 15: On the 1200 kN machine, which is optimized for clean rooms, an autoinjector housing is produced in a cycle time of approx. 12 seconds, using an innovative 4-cavity mold from Zahoransky.

What makes it special is that, thanks to indexing technology with an integrated rotary unit and individually controlled, servo-electric needle shut-off nozzles, the cycle time is significantly reduced compared to conventional tools. Automation is handled by a 6-axis robot that removes the components when the tool is closed. Saxe’s compact solution includes optical quality control and automatic container changeover – fully integrated into the machine’s Axos control system. Tool cooling is also cleverly solved: Mouldflo water distributors integrated into the clamping plate record and monitor temperature differences and flow rates in real time.

Other partners involved in the exhibit are Ewikon (Hot runner technology), Petek (cleanroom technology), HB Therm (temperature control units), Piovan (material feed), Sabic (material), SAX Polymers (masterbatch) and bfa solutions (MES).

Exhibition information and appointment scheduling

Netstal is the official wreath partner of the ESAF 2025 Glarnerland+

From August 29 to 31, Glarnerland+ will be swinging and celebrating: A stone's throw from our headquarters, the Swiss Wrestling and Alpine Festival (ESAF) will take place on the grounds of Mollis Airport. As a company firmly anchored in the region, Netstal supports the organizing committee and is a proud wreath partner of the ESAF 2025 Glarnerland+.

This is Swiss tradition at its best: the Swiss Wrestling and Alpine Festival, or ESAF for short, takes place every three years at different locations and regularly attracts over 400,000 spectators, making it the largest recurring sporting event in Switzerland. At the ESAF, the country’s best wrestlers compete in traditional Swiss wrestling, accompanied by competitions in stone put and a great festival culture with yodelers, flag-wavers and alphorn players. The winner receives the prestigious title of “Schwingerkönig” (wrestling king) as well as a live prize of a full-grown bull, the so-called “Muni”.

Pictures: ESAF 2025 Glarnerland+ / Maya Rhyner

Netstal’s support for the ESAF 2025 Glarnerland+

Holding such a large event is an organizational tour de force for which a good spatial infrastructure is indispensable. The ESAF organizing committee has been using meeting rooms at the Netstal headquarters for meetings and other presentation events since 2021.

A temporary shuttle service will be set up in the region to transport visitors between the more distant train stations, camping and parking areas and the festival grounds. The necessary bus terminal will be set up in the Netstal parking lot. In addition, our area will be used as a disposition point for the large festival parade, which traditionally takes place at the start of the ESAF.

Great sport against a magnificent mountain backdrop. The ESAF 2025 Glarnerland+ will take place on the Mollis airport site. A little further north are the Netstal factory halls (Photo: ESAF 2025 Glarnerland+ / Maya Rhyner)

As official wreath partner, we are looking forward to a fantastic ESAF 2025 Glarnerland+.

The + stands for the Zürichsee-Linth, March Höfe and Sarganserland regions bordering the canton of Glarus, which are also supporting ESAF 2025.

10.5 % energy saving with a thin-walled cup

With adaptive system pressure reduction, we presented a retrofittable option in 2023 that allows manufacturers to effectively save energy costs. The potential varies depending on the application.

Initial situation:

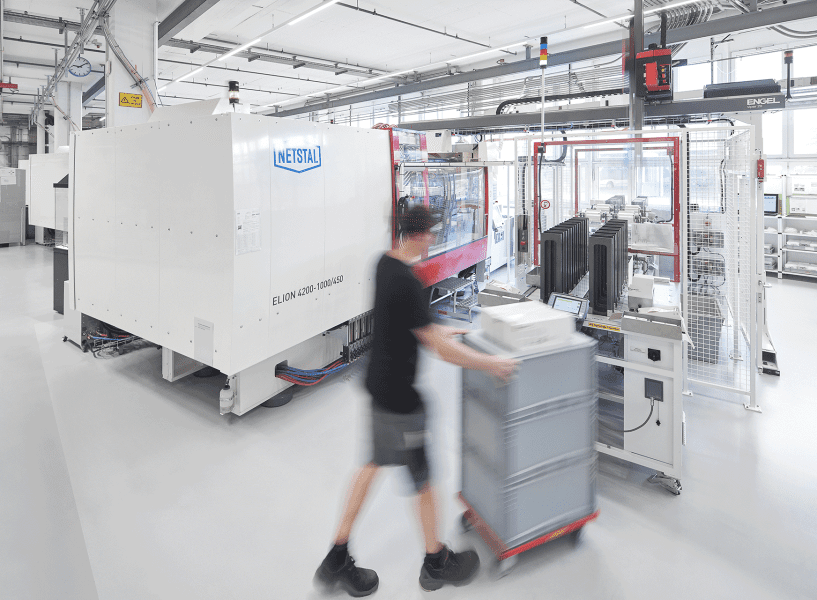

Using a coffee cup, we wanted to find out whether the calculated savings can be confirmed in practice. The thin-walled cup is produced in a 6-cavity mold on an Elion 2800 with a cycle time of 3.9 seconds. The shot weight is 95 g.

Solution from Netstal:

The application described was tested extensively with activated system pressure reduction. With the option activated, the injection molding machine requires around 10.5% less energy. A considerable reduction in costs and a relevant reduction in the CO2 footprint.

Please accept YouTube cookies to play this video. By accepting you will be accessing content from YouTube, a service provided by an external third party.

If you accept this notice, your choice will be saved and the page will refresh.

Adaptive system pressure reduction

The hydraulic system of Netstal injection molding machines is designed for a maximum operating pressure of 250 bar in order to be able to cope with peak loads without any problems. Depending on the application, a lower value would also be sufficient. This is where Netstal comes in with the new system pressure reduction and optimizes energy efficiency. In automatic mode, the adaptive control system determines the optimum point at all times and adjusts the system pressure accordingly. With the same or even increased productivity, the energy consumption for providing the system pressure is reduced to a minimum. A lower load on the components also has a positive effect on machine availability and overall service life.

Retrofit maximum efficiency: Optimize your operating processes sustainably with Smart Operation

Greater efficiency and productivity can also be achieved with existing machines. With Smart Operation, we offer you an innovative solution for optimizing operating processes in injection moulding production. Retrofitting is possible for all Netstal machines from control system generation Axos 7.

In high-performance applications, the aim is often to keep reducing cycle times in order to be able to produce even more. However, sometimes these gains are eaten up by small efficiency losses. This means that non-technical downtimes are either not taken into account or are regarded as unavoidable. With Smart Operation, you can reliably eliminate such downtimes and increase productivity.

More efficiency can be retrofitted: After the conversion, the Axos control unit has 4 additional Smart Buttons and a software update

(Move the slider to the left to see the controller after the conversion)

Sales increase in the six-figure range

A customer example: In the production of dental components, the injection molding machines have to be stopped at regular intervals in order to lubricate the tools. As the plant maintenance staff are unable to operate the injection molding machine, specialist personnel have to be called in each time. As the specialist has to look after several systems at the same time, there are always waiting times of several minutes. However, this adds up over the year and the negative impact on productivity is significant.

With Smart Operation, we were able to offer this customer an optimal solution. By anchoring specific production processes in the machine control system, a guided operation was created that can also be carried out error-free by maintenance personnel after a short briefing. Today, this customer has equipped several machines with Smart Operation and reports a six-figure increase in turnover. This is solely due to the elimination of the many short waiting times. Today, the plant maintenance staff independently access the machine, stop production, lubricate the tool and then restore the entire production cell, including the removal robot and packaging system, to production status.

Intuitive and safe operating concept eliminates non-technical downtime

The Smart Operation concept is based on anchoring operation-relevant scenarios and processes in the control system and changing the operating status at the touch of a button. A total of 4 of the so-called “Smart Buttons” are available. A color code on the main screen clearly indicates which buttons can be used to continue. The relevant buttons light up in the corresponding colors. For example, red for “Stop cycle mode” or green for “Start cycle mode”. If certain work steps are also required, such as ejecting the injection unit, this is displayed as an instruction. The execution must be confirmed before the next step can be continued. The principle is as intuitive as operating a coffee machine that indicates when the coffee grounds container needs to be emptied or a descaling program needs to be carried out.

Another application scenario is the rapid rectification of faults during the night shift. With Smart Operation, most faults can be rectified immediately by shift personnel. There is no need to wait until an application engineer arrives.

Users of Smart Operation benefit in several ways: the implementation of clearly defined processes protects capital goods from improper operation and reduces the risk of operating errors. Repair costs are reduced and system availability increases. Situational user interactions drastically reduce the amount of training required. Instructions printed on paper are no longer necessary. Smart Operation significantly increases overall production efficiency.

We always recommend adding Smart Operation for new machines. Smart Operation can be retrofitted to existing machines with Axos 7 and Axos 8 at any time. We will be happy to provide you with an efficiency consultation for optimum operating processes with Smart Operation and prepare a retrofit offer tailored to your needs.

Go to LinkedIn to read the Success Story with SFS from the year 2022:

Transparent, thin-walled and highly recyclable: Packaging made from PET

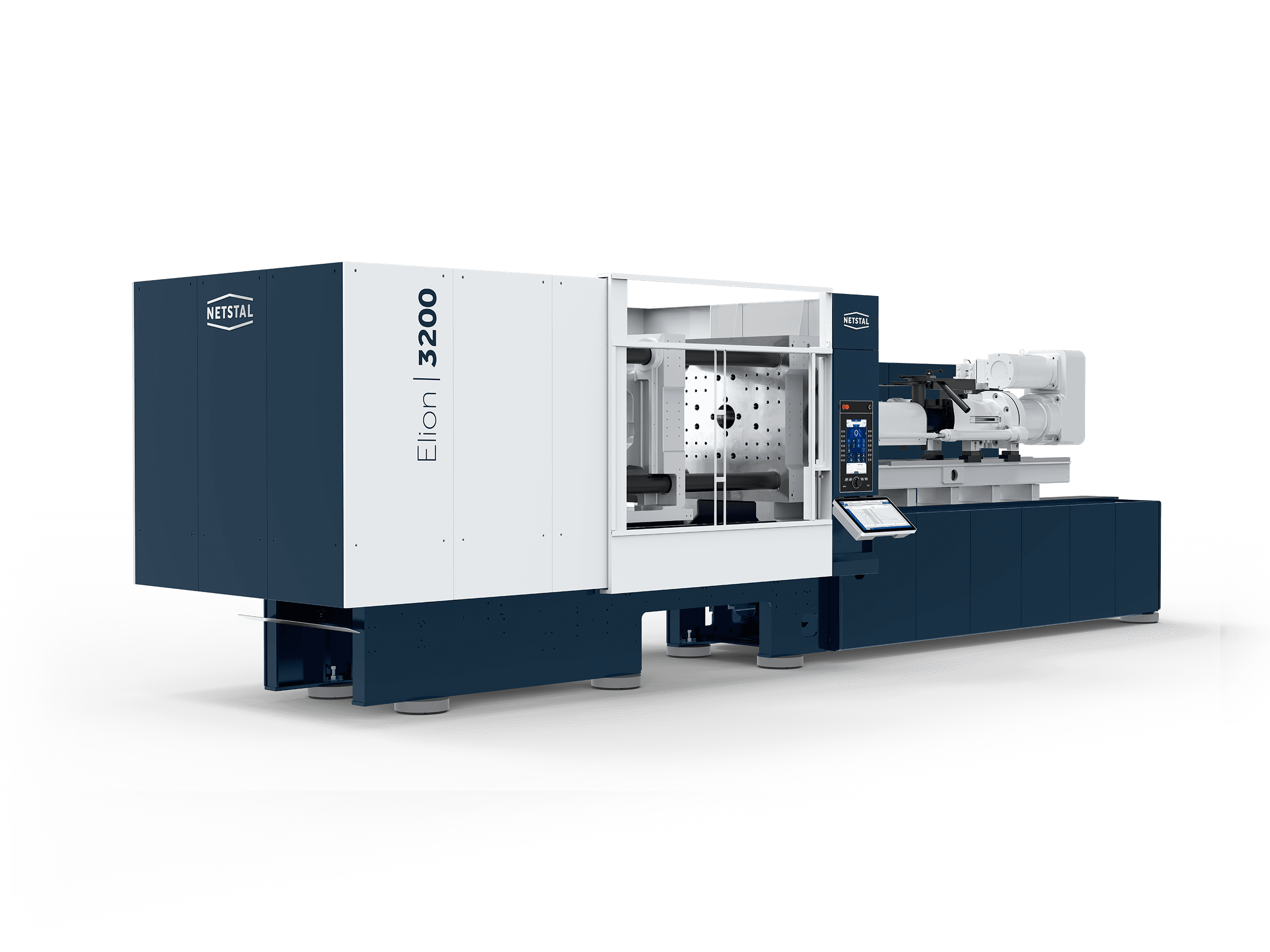

As a manufacturer of plastic packaging, do you want to make products from PET in the future or are you generally interested in possible alternatives to PP? Then you should plan a visit to Netstal at the NPE. In Orlando, we and our system partners will be demonstrating what sustainable and recyclable thin-wall packaging can look like. At our stand W223, we will be producing a thin-wall cup made of 100% PET on a hybrid Elion 3200. The transparent cup can be processed together with empty PET bottles into high-quality recyclates.

The recycling rate for thin-walled plastic packaging, such as cups for dairy products or spreads, is still low worldwide. This contrasts with PET bottles, which play a pioneering role in recycling. Across Europe, half of all PET bottles placed on the market were already recycled in 2020. The trend is also rising worldwide. However, if all types of PET packaging are considered, the rate is still 35% (source: Statista). Due to its good recyclability and the established recycling systems in several countries, the idea of using PET for thin-walled packaging and making it specifically recyclable is an obvious one. PET packaging must meet certain criteria so that it can be easily collected via the established collection systems and processed into rPET regranulate in the recycling plants together with PET bottles. This is an important prerequisite so that new bottles and packaging can be created from all PET containers.

"Clear packaging or the absence of color additives is preferred for PET packaging in order to achieve the purest possible quality of rPET. At the NPE, we will be showing such a PET cup that is optimized for recycling."

Reto Gmür, Produktmanager Packaging

The thin-walled PET cup weighs around 15 g

Sustainable PET thin-wall cup produced in a climate-friendly way

We have developed such a recycling-optimized solution for the NPE and in collaboration with our system partners. The clear cup weighs around 15 g and has a filling volume of 450 ml. We process virgin PET from the Eastman Chemical Company. We put the cups into the NPE recycling program so that the material remains in the PET cycle without loss. The labels are also made of PET and are provided by the Belgian IML specialist Verstraete. Our Canadian partner StackTeck provides the test mold with two cavities as well as the IML robot that inserts the labels into the cavities and removes and stacks the finished cups.

The PET cup is injection molded in a cycle time of around 4 seconds on our Elion 3200. With its electric toggle clamping unit and hybrid injection unit, the injection molding machine delivers the necessary speed, performance and dynamics. By recuperating kinetic energy from the clamping unit, the Elion is one of the most energy-efficient injection molding machines on the market. In high-speed applications, the Elion is in efficiency class 8 and higher of the latest Euromap 60.1 standard. The unit with RFC injection control shines with its leading shot-to-shot consistency. This is only available from Netstal in this form: The force-dependent pressure changeover is independent of the material properties and enables our customers to keep the part weight within tight tolerances at all times. You do not pay any extra for the leading Netstal precision, because the highest precision has been standard at Netstal for decades.

High-performance and energy-efficient injection molding machine: the Elion 3200

The Elion 3200 is equipped with the optional adaptive pressure reduction. This optional function helps you to save energy. If the pressure reduction is activated, the hydraulic system pressure is permanently adjusted to the optimum point. This option offers you enormous advantages. With a lower pressure, the axles of the machine are less heavily loaded. This has a positive effect on availability. However, the main benefit is the further reduction in power consumption. You produce particularly efficiently and at the lowest unit costs.

World record: Alltrista manufactures 128 beverage caps every 1.9 seconds

At the NPE you will experience high-performance injection molding in its purest form at Netstal. Together with our system partners and customer Alltrista®, we will be presenting the world's most powerful production system for lightweight beverage closures. The key data are impressive: 26mm water closures, 128 cavities, 1.9 second cycle time, 25 % material savings. Read the story to find out how this project came about.

At Alltrista, the production of 26mm water closures is running at full speed on two production lines. Anyone familiar with the subject quickly realizes that a very special application is in use here. You rub your eyes in amazement: is this a mold with 128 cavities that is moved here with a cycle time of 1.9 seconds? Can that be true? Yes, it is: Alltrista is the first company in the world to produce over 3 billion closures with a program like this. To be precise: 3.1 billion caps. We can announce this with a broad chest: We are proud to be part of this success story with our leading injection molding technology.

But let’s hear from our customer first.

“We wanted to be the first manufacturer to operate a system with 128 cavities in less than 2 seconds. With Netstal, z-moulds and Intravis, we have found the best system partners for this project. Each company is a leader in its field and the combination is unbeatable from our point of view. We simply thought: if this is to work, we need exactly these three partners. With the first two 128-cavity systems, we are now producing more efficiently than ever before, can deliver at any time and delight our customers. This has given us an enormous competitive advantage.”

Christopher Navratil, CTO at Alltrista’s parent company

Innovative mold-machine combination pushes physical boundaries

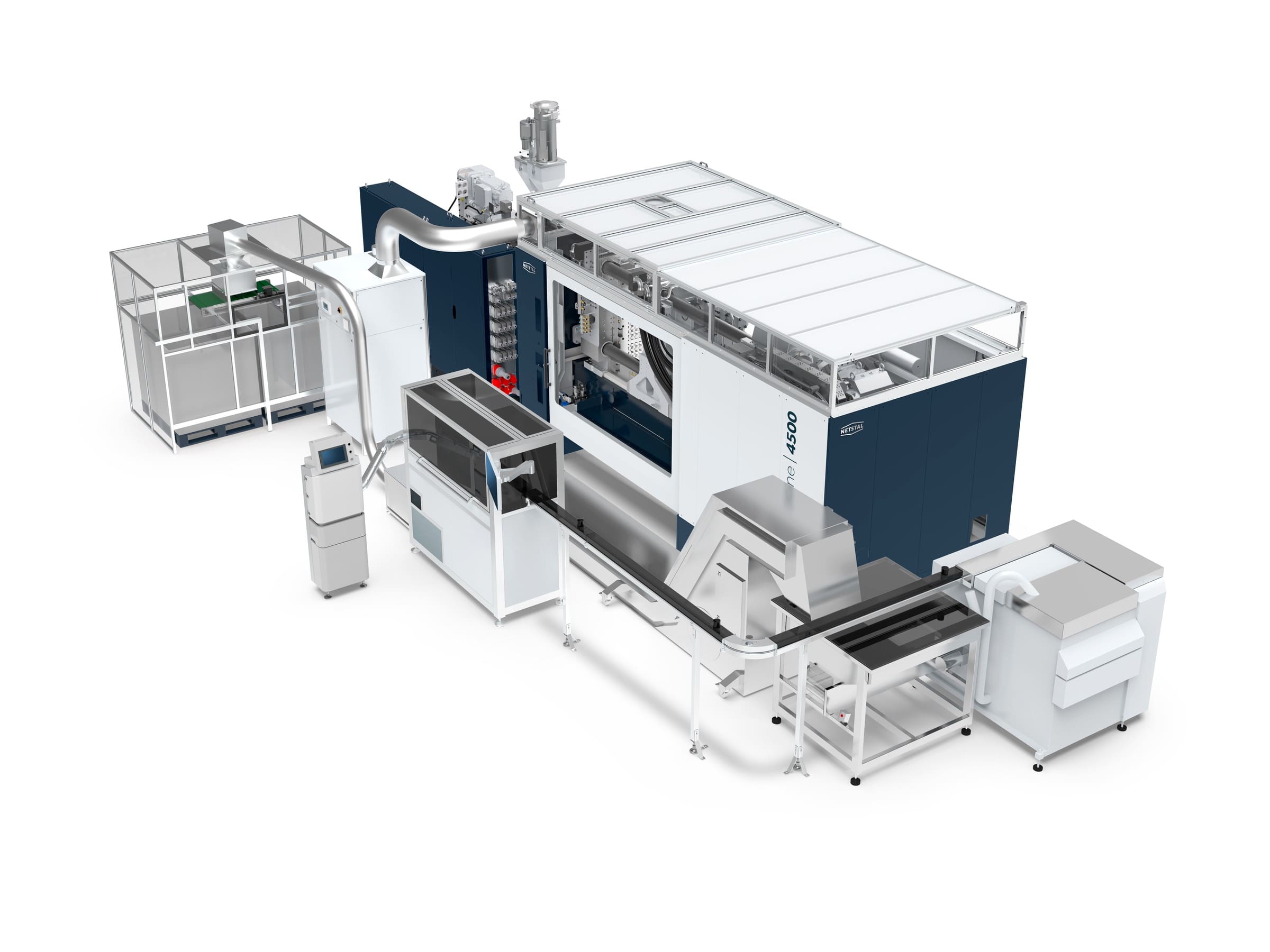

Let’s go into a little more detail. Water closures of the 26 mm type are produced for still water that is filled into PET bottles. Thanks to an innovative design, z-moulds was able to make its mold as small and light as a 96-cavity mold. This results in decisive advantages for the user. Compared to previous 128-cavity molds, the mold fits into a machine with a smaller tie bar distance. The compact design of the mold also means that less mass needs to be moved. An important prerequisite for the fastest possible cycle times. Consequently, running 128 cavities with a cycle time of less than 2 seconds is a world first. At Alltrista, the lines run at around 1.9 seconds. Occasionally it is also 1.85 seconds. The complete production system also requires very little floor space. Each line produces 1.55 billion closures per year on around 50 square meters. More output per square meter of production area is currently not possible.

Maximum productivity in a small space: At around 50 square meters, the Alltrista production system only requires a small footprint

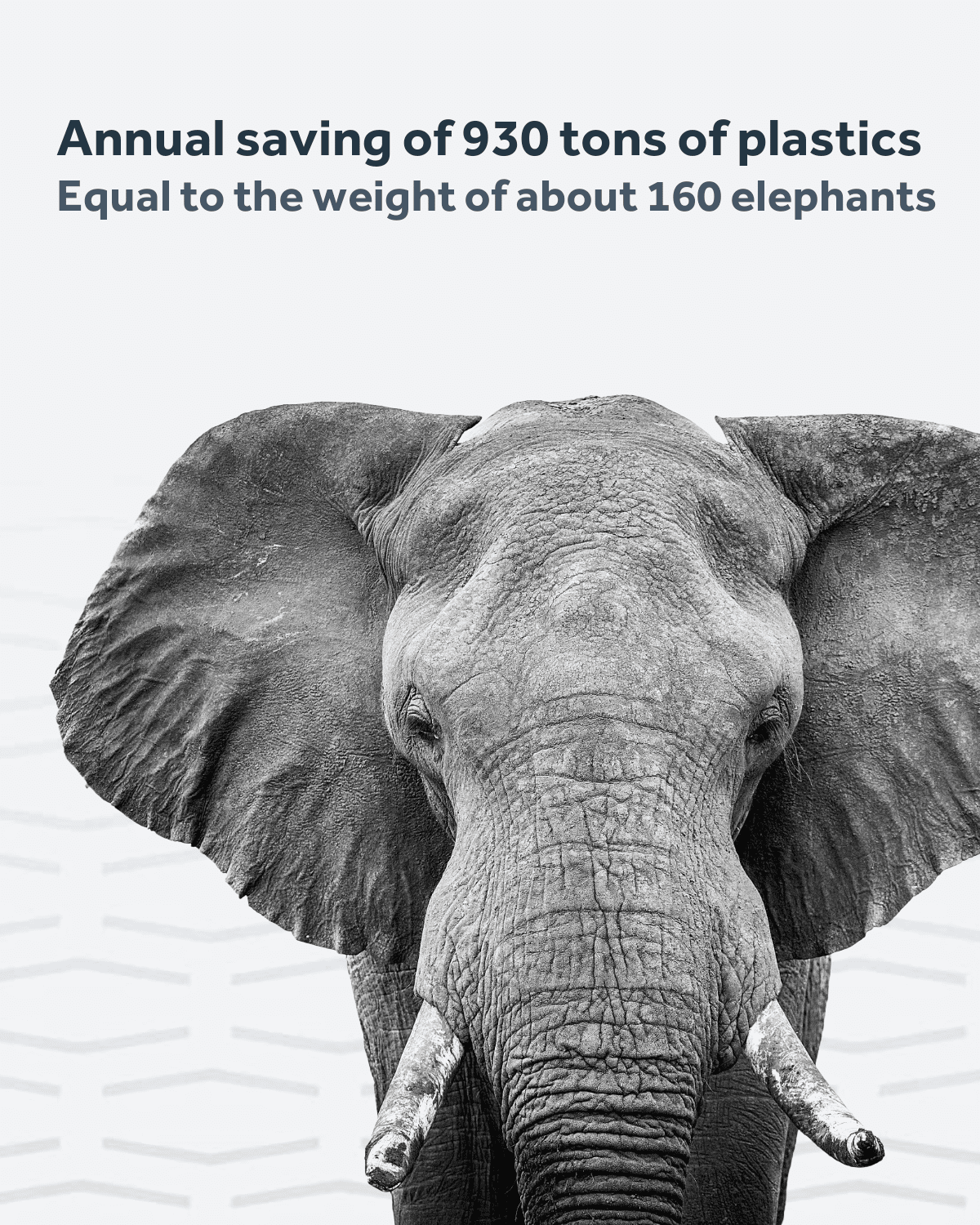

Significant energy savings and 25% less plastic

More output is a great thing. Add to that savings on materials and electricity and you have efficiency at its peak. Comparative measurements have shown that the Elios 4500 with 128 cavities consumes around 12% less electricity than comparable machines from the competition. However, these were equipped with only 96 cavities. In addition, the application engineers at Alltrista were able to make the closures 25% lighter and therefore much more sustainable without compromising their function. Based on the full programm productivity of 3.1 billion closures per year, Alltrista saves over 930,000 kg of material. This corresponds to the weight of approximately 160 adult African elephants.

Intravis high-speed downstream quality control

However, the enormous number of caps is not yet ready for dispatch immediately after demolding. Before they can be filled into octabins, the closures pass through the downstream equipment of our system partner Intravis. The CapWatcher Q-Line carries out a comprehensive 360° full inspection of the closures. Today’s computing power makes it possible: up to 80 closures per second are checked for more than 40 quality criteria with an accuracy in the hundredth of a millimeter range. The cavity-related inspection is carried out with up to nine high-resolution cameras. An enormous amount of data that is processed in real time. The high performance gives Alltrista the certainty at all times that the closures are flawless immediately after production and that customers are only supplied with good parts.

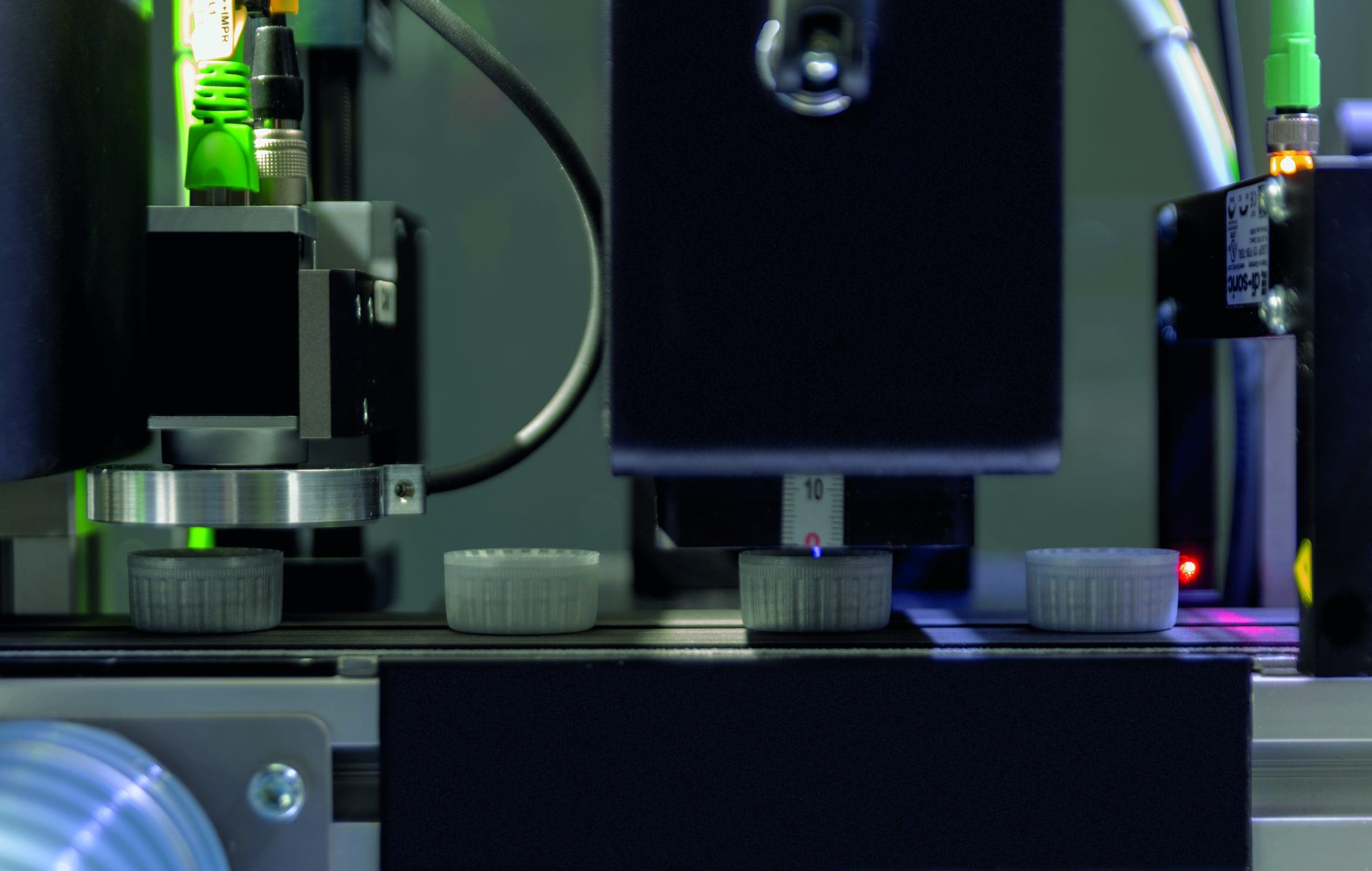

A look inside the CapWatcher Q-Line. The system uses 9 high-resolution cameras to check up to 80 caps per second for more than 40 quality features

Alltrista: Innovative contract manufacturer from South Carolina

All in all, the Alltrista production system for 26 mm closures is the new benchmark in terms of speed, productivity, efficiency and sustainability. Two identical system solutions for closure production are currently in production at Alltrista. Alltrista Plastics LLC specializes in innovative, high-volume precision manufacturing. From rigid packaging and custom molded solutions to assembly, filling and kitting, Alltrista supports customers in the medical, healthcare and consumer goods industries with a wide range of products and services. The company’s ability to assemble strong teams on a project-by-project basis allows it to be flexible on even the most challenging orders.

Christopher Navratil confirms: “This closure application is proof of our innovative strength and our unbridled desire to keep pushing the technological boundaries. We are proud that, together with the experts from Netstal, z-moulds and Intravis, we were able to increase productivity by at least 30 percent in this project. For us, this is a prime example of how companies from the USA can work successfully with partners from Germany, Austria and Switzerland.”

Alltrista attaches great importance to the continuous improvement of its own sustainability. The company was audited by Ecovadis in 2023 and received the silver medal for its sustainability performance to date. Alltrista ranks in the 88th percentile of all companies assessed by Ecovadis and among the top 7% of peer companies.

Witness the Alltrista production system live at the NPE in Orlando

As mentioned at the beginning, we will be presenting an identical production system for 26 mm closures at our NPE stand. Alltrista will have its own staff on our booth to provide information from the customer’s perspective. For detailed information on all the company’s services, we also recommend a visit to booth S22065 in the South Hall, where Alltrista will be showcasing its full range of contract manufacturing and injection molding products and services.

Visit our NPE exhibitor profile and plan your visit:

CAP-Line

At the NPE you will see a Netstal machine labeled CAP-Line for the first time.

With the CAP-Line, we offer specifically pre-configured injection molding machines for closure applications. The CAP-Line 4500 on our stand is based on the high-performance Elios platform and is equipped with various features for the efficient production of beverage closures.

The CAP-Line 4500’s all-electric toggle-type closing unit with a drying time of 1.4 seconds enables cycle times of less than 2 seconds. Thanks to the optimized barrier screw, we can use a smaller injection unit. The new screw design ensures a higher plasticizing performance and a better degree of homogenization. Further options are available for individual optimizations, such as our four-button Smart Operation or the adaptive system pressure reduction, with which you can achieve additional energy savings.

With the new concept for the CAP-Line, we are aligning our portfolio even more closely with our customers’ applications. As a closure manufacturer, you benefit from a system that is individually tailored to your application. However, pre-configuration speeds up the consultation and quotation process so that delivery times for the machine are as short as possible.

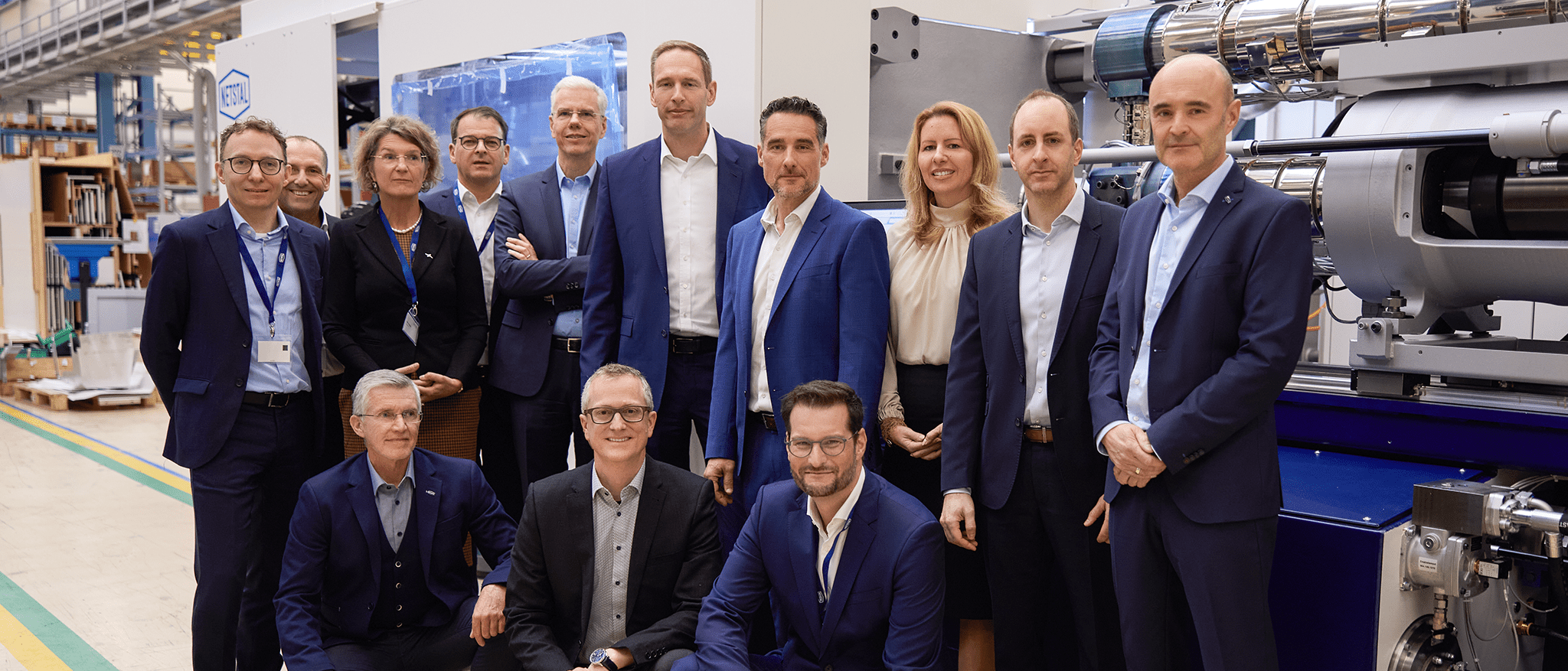

Netstal becomes a member of the Krones Group

Netstal will have a new owner: Krones acquires 100 percent of the Netstal Group from KraussMaffei. The takeover agreement was officially signed on February 6. The transaction is expected to be completed in the first half of the year. Our customers in all application areas will benefit from the opportunities arising from this change.

We will not have to introduce Krones to our customers in the beverage industry. This may be different for Netstal users and our partners from the thin-wall packaging and medical technology sectors. That is why we are pleased to offer a brief overview of the Krones Group: Krones is the market leader in lines and machines for the production, filling and packaging of beverages and liquid foodstuffs in PET and glass bottles as well as beverage cans. With its products, the German company covers the entire production, filling and packaging process as well as the material flow in the manufacturing plant and integrates the corresponding IT systems. It also carries out complete factory planning projects for the beverage industry. Headquartered in Neutraubling, Bavaria, the company employs around 18,000 people worldwide. Consolidated revenue in 2022 amounted to 4.209 billion euros. Krones AG is listed on the Frankfurt Stock Exchange and is currently included in the MDAX share index.

Looking forward to a successful collaboration (from left): Danijela Karelse (CFO Netstal), Renzo Davatz (CEO Netstal), Christoph Klenk (CEO Krones) and Uta Anders (CFO Krones)

The Krones Group stands on an extremely solid economic and technological foundation and can look back on a very successful development over the past decades. We are convinced that Netstal can only benefit from this new foundation in order to achieve the targeted growth in all areas.

“This transaction is a milestone in the long history of Netstal. Krones opens up strategic perspectives that were previously not possible. The potential for more customer benefits and growth in the beverage sector is obvious. The opportunities in the medical and thin-wall packaging applications are equally exciting. It is a pleasure for me to continue the strategic direction we have taken together with Krones to an even greater extent.”

Renzo Davatz, CEO Netstal

Leading solutions for the beverage and packaging industry as well as medical technology

However, major changes can also lead to questions. We would therefore like to emphasize at this point: With Netstal, we will continue to focus on you and your needs. Your personal contacts in sales and service will continue to be available at the headquarters in Näfels and in the subsidiaries. The processing of orders and projects will also not be affected. You will always receive leading technology from us in proven Netstal quality.

Our market orientation will not change. Krones would like to work with us to further develop the Netstal strategy and lead it to success. This applies to all strategic application areas. Netstal will continue to offer leading solutions for the efficient production of PET preforms, beverage closures and thin-wall packaging. In medical technology, Netstal is excellently positioned in high-speed mass applications for laboratory and consumable materials. This market position is to be further strengthened in the future. With its leading injection molding technology for medical applications and thin-wall packaging, Netstal supports Krones’ strategy of diversifying into the medical/pharmaceutical market as well as the food and personal care sectors. Netstal will continue to manage its business independently, benefiting from Krones’ international footprint and economies of scale.

Injection Molding Competence Center Näfels

Despite a challenging environment, we believe we are well equipped for the future. With Netstal, we have a competitive product portfolio and are constantly working on further innovations. Always with the aim of further increasing your added value. Under the umbrella of Krones, we will continue to expand our leading position in the top performance segment. Our headquarters in Näfels will be further developed into an injection molding competence center. This will ensure your supply of innovative injection molding technology and associated services as well as digital enhancements for applications in the top performance segment.

We will be happy to answer any questions you may have on this and other topics.

You can find more information on our leading solutions on the industry pages for preforms, closures, packaging and medical technology.

All information about Krones can be found at www.krones.com.