Our highlights at Fakuma 2023

Visit us at Fakuma (Hall B3, Booth 3119), where we will be using the injection compression molding process to produce thin-wall packaging specially designed for the circular economy. This process allows you to produce packaging with minimal wall thickness and save valuable resources. With the new Axos 9 control generation, you can take efficiency and precision in your production to a new level. Visit our booth and get inspired.

Discover lightness: Our innovative 200 g yogurt cup presents itself in a feather-light design. With its part weight of only 5.4 g, it sets new standards. What makes this cup particularly sustainable: both the cup and the label are made of 100% recyclable polypropylene (PP). This allows for easy recycling and strengthens your contribution to the circular economy. Unlike conventional in-mold labels, the label does not stick in the recycling process. It detaches without affecting the PP recycling stream. Thanks to efficient separation of the ink particles from the pure PP, high-quality regranulate can be produced.

The use of injection compression molding (ICM) reduces the weight of the cup by an astonishing 34%. This innovative approach goes hand in hand with our sustainable vision. In addition, by combining the ICM process with product optimizations, we have reduced the packaging volume by an impressive 27% – another step towards sustainability and resource conservation.

Sustainable cups, efficiently manufactured

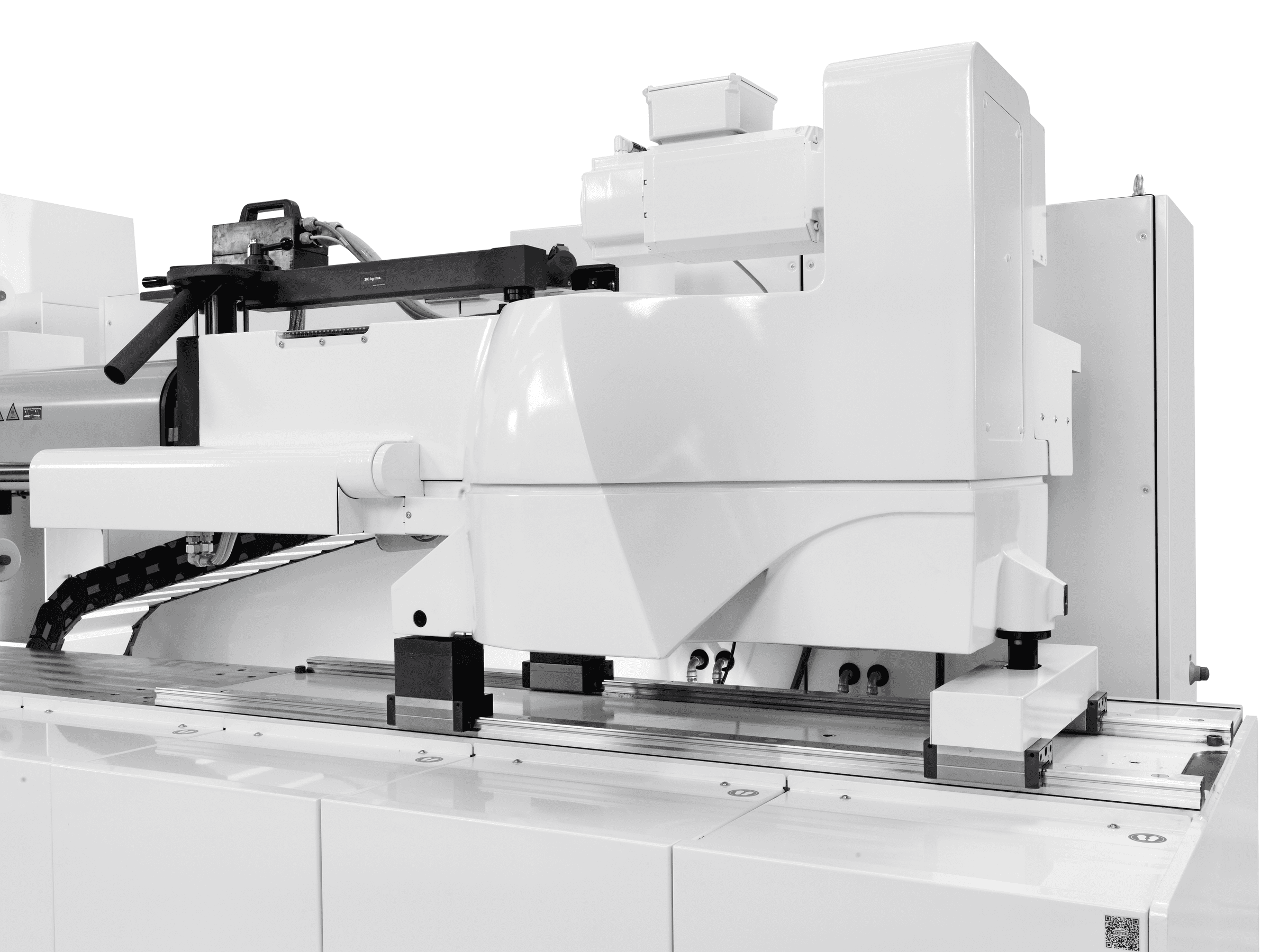

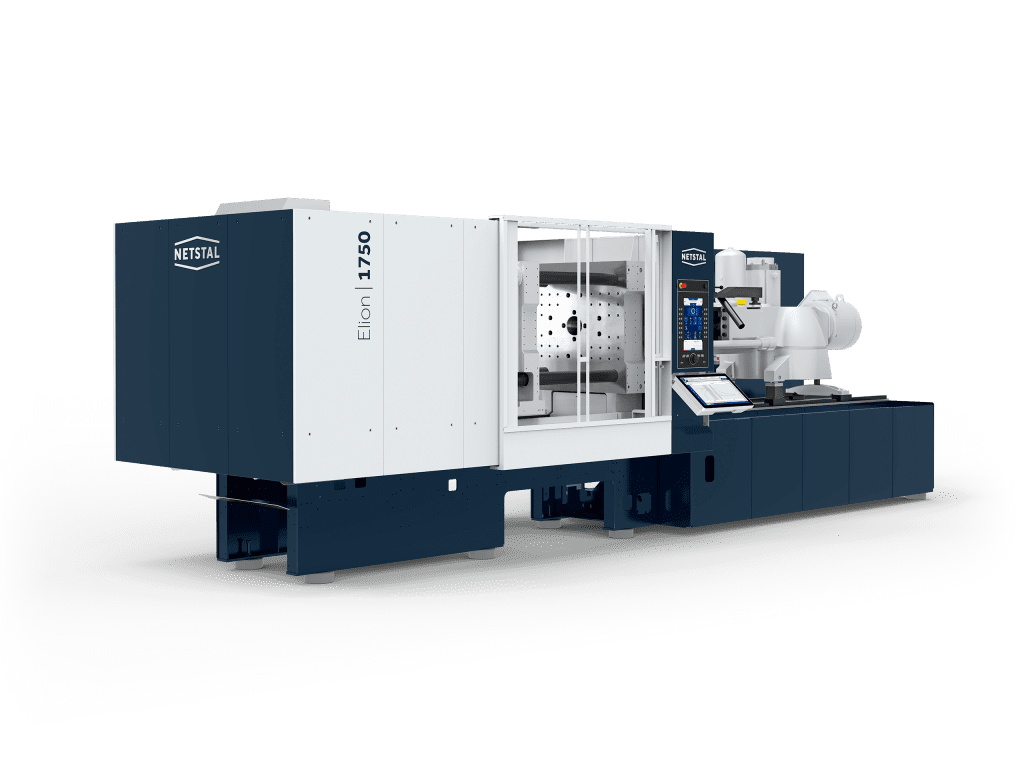

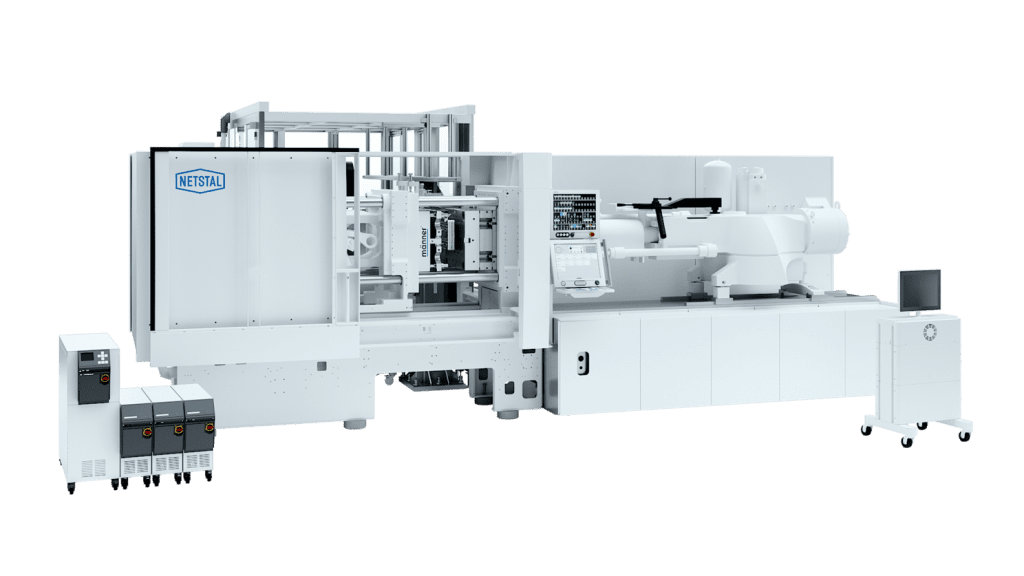

Experience our environmentally friendly cup, produced with energy-efficient production processes. The thin-wall packaging for dairy products is produced in 4 cavities and requires only 2.7 seconds per cycle – thanks to our Elion 1750 machine with hybrid injection unit. At Netstal, we focus on reliable performance and set standards in terms of energy efficiency. Our machines work precisely and economically to conserve resources and ensure sustainable production. With the optional adaptive system pressure reduction, we have further improved the efficiency of our hybrid machines. The new function is a technological highlight that always determines the optimum point in automatic mode and adjusts the pressure in the hydraulic system accordingly. This results in minimized energy consumption to provide the required system pressure, depending on the application. At Netstal, we are committed to sustainable solutions that are both efficient and environmentally friendly.

The application is the result of a successful cooperation with renowned high-end system partners. These include Glaroform, Beck Automation, SABIC, IPB Printing, motan, Regloplas and Uniform Color. Together we have worked on this future-oriented solution. A key development partner in this collaboration is Switzerland’s Emmi AG, one of the largest dairy product bottlers and a pioneer in the food industry. The specifications for this innovative packaging were developed in close consultation with Emmi to meet the highest demands of the food industry. Particular attention was paid to maintaining the previous appearance of the cup while optimizing recyclability.

Operate the machine intuitively with the new Axos control system

Experience intuitive machine operation with the new Axos 9 control. At Fakuma, we are bringing Axos 9 to the machines of the Elion and Elios series. Call up the full performance potential of your Netstal machine. The integration of Smart Operation makes machine operation in the production environment fast, safe and extremely effective. Smart Operation is still available as a paid option in Axos 9.

Further packaging application with Netstal in Hall A3

Don’t miss a detour to Hall A3 either. A fully electric Elion 2200 awaits you, which we will present at our Turkish mold partner Ceylan. There, 150 g margarine trays with IML decoration are produced in 4 cavities. The cycle time is 3.8 seconds with a precise shot weight of 42 g. The IML system used, which includes side removal, camera control and packaging unit, comes from Eurasia Robotic in Turkey. Stop by and see this turnkey production line live at the Ceylan booth in Hall A3, Booth A3-3105.

Plan your trip to Fakuma and schedule an appointment with us:

Introducing: Our new brand identity

As of today, Netstal has a new brand identity. The values of leading, reliable and value-creating form the core of our tradition-rich brand. In doing so, one mission is our top priority: We want to work with you to increase your production efficiency and maximize your value creation. With Netstal, you get not only leading injection molding technology of the highest Swiss quality, but also a reliable partnership at eye level.

You can find out more here here

With a contemporary corporate design, we are visually communicating this positioning to the outside world. You have probably already noticed: The heart of the new brand identity is the graphically revised company logo. In the modernization process, we have been careful to respect our tradition. The familiar diamond shape, which has been opened up at the sides and forms a harmonious frame for the lettering, remains clearly recognizable. In a figurative sense, this also says that we are opening ourselves up to new opportunities and challenges. These include topics such as digitalization and sustainability, as well as the conscious use of the valuable material plastic. At the same time, we remain true to our core competence, the injection molding machine.

All technical data available online

From now on you can get information about our products and services here on our new website. A highlight is certainly new download center, which you can reach here:

Here we offer you a clear overview of all current series and their technical data. With practical filters you can limit the selection according to application area, drive technology, shot weight and column distance. In the English language version, the data sheets are available for download with either metric or imperial units of measurement. A note for you: The data sheets also contain a download link to the foundation plan.

New series coating for injection molding machines

With the change to the Axos 9 control generation, we are also applying our new design to the current machine portfolio. The dominant colors for non-medical machines are dark blue and white. Three-dimensional logos in chrome steel look emphasize the high quality of Netstal machines. Please feel free to visit our product pages for more views.

Visit us at Fakuma

Trade shows are and remain particularly important events for us. Nowhere else can we share our enthusiasm for injection molding with so many customers in such a short time. For these important personal encounters, we have created the best setting with our new and sustainable trade show concept. The booth, which is divided into two areas, impresses with its simple naturalness and modern spaciousness. In the front area, the focus is on the running machine exhibit for sustainable thin-wall packaging. The catering area has been spatially demarcated to allow for consultation meetings in as quiet an atmosphere as possible. We cordially invite you to visit us in Friedrichshafen. You will find us at our new regular place in hall B3 at booth B3-3119.

For more info on our trade show appearance, click here: Fakuma 2023

We hope that you will be as enthusiastic as we are about our new appearance. If you have any questions about this or any other topic, please do not hesitate to contact us. Please do not hesitate to contact us.

Netstal awarded EcoVadis Bronze

We waited with great excitement for the result of our first evaluation by EcoVadis. Accordingly, we were delighted to receive the bronze medal. Our sustainability performance is thus considered "good".

We reduced our CO2 footprint by 80%

EcoVadis is the world’s largest provider of sustainability assessments for companies. The assessments are not only about the important topic of environmental protection. In total, EcoVadis considers 21 sustainability criteria from the areas of environment, labor and human rights, ethics and sustainable procurement. In the area of environmental protection, we have achieved quite a bit in recent years. Compared to 2019, we have reduced our CO2 emissions by 80%! Of central importance was the switch to climate-neutral district heating from the Bilten waste incineration plant. As a result, we were also able to switch the process heat required in production from gas to district heating. Michael Rocholl, Head of Quality and Process Management, explains: “This has enabled us to completely decouple ourselves from gas. The remaining CO2 emissions are attributable to electricity consumption and the currently operated vehicle fleet. With additional measures, we will further reduce our energy consumption.”

In view of global warming with longer dry periods, we are also paying attention to our own water consumption. Whereas a decade ago this was still 200,000 m3, last year we were able to reduce the flow to around 75,000 m3. “In 2023, we want to reduce our consumption to around 60,000 m3. We have launched a preliminary study to derive suitable measures,” says Michael Rocholl.

In terms of sustainable procurement, we already rank among the top 7% of all companies assessed in the special machinery sector. By further concretizing our guidelines, optimized risk assessments, internal training, and intensified monitoring, we want to further increase our overall EcoVadis score in the coming years.

Highest-performance injection molding technology, sustainably manufactured in Switzerland

By scoring well in our first attempt, we are not only demonstrating a strong commitment to environmental protection and society, but also strengthening our own future viability. This is because more and more companies expect an EcoVadis rating from their suppliers and take it into account in their purchasing decisions. Renzo Davatz confirms: “We will continue to work on our sustainability. They can be confident that they are always making the best choice with our technologically leading injection molding machines. Not only do they offer them the highest performance capability and outstanding energy efficiency, but they are manufactured in Switzerland to ever higher sustainability standards.”

As a customer, you therefore benefit several times over with Netstal: You produce with maximum efficiency on our particularly sustainably manufactured machines. This in turn will have a positive impact on your own EcoVadis ranking.

An investment that pays off: Adaptive system pressure reduction makes injection molding machines from Netstal even more energy efficient

A new option is now available for hybrid Netstal machines: Adaptive system pressure reduction permanently determines the optimum operating pressure in the hydraulic system. The retrofittable feature lowers power consumption while maintaining at least the same productivity, reduces the CO2 footprint and pays for itself in a short time.

Can it be a little less? In order to handle peak loads without any problems, the hydraulic system of hybrid Netstal injection molding machines is designed for a maximum operating pressure of 250 bar. Depending on the application, a lower value would also be sufficient. This is where we come in with the new system pressure reduction and make our machines even more energy efficient. In automatic mode, the adaptive control system determines the optimum point at any time and adjusts the system pressure accordingly. With the same or even increased productivity, the energy consumption for providing the system pressure is reduced to a minimum. A lower load on the components can also have a positive effect on machine availability, maintenance intervals can be planned more efficiently, and the machine can produce for longer time.

Smaller carbon footprint and higher cash flow

In addition, there are further ecological and economic advantages for Netstal customers. The lower energy consumption of the machine also reduces the user’s ecological footprint. Depending on the regional electricity mix, less CO2 is emitted. In most cases, the small surcharge pays for itself within a few months. The payback period varies depending on the region and electricity costs. In some countries, investments in more energy-efficient and climate-friendly production facilities are subsidized with government grants.

We will be happy to calculate your individual savings potential and show how you can manufacture identical products at a lower cost and with a smaller CO2 footprint. Finally, lower consumption costs and subsidies have a positive effect on the company’s cash flow. The lower load on the equipment helps extend the life of the machine. The acquisition costs per year of use are lower. Likewise, at the end of the targeted useful life, a higher price can be obtained on the used machine market. Netstal machines are already considered to be particularly stable in value. With the new adaptive system pressure reduction, we once again provide you with more added value and increase the distance to our international competition.

Adaptive system pressure reduction is optionally available for all hybrid Netstal injection molding machines running the latest aXos version (release 8.6.0).

Retrofitting of existing machines is possible: Please get in touch with your local service contact or with Soroush ZanjaniPoor.

A perfect pipette tip, please!

Pipette tips are precision articles whose production is complex and technically demanding. In addition to a high-performance, repeatable injection molding machine, high-precision molds, fast robotics with valid part inspection, and automated networking of all components are required to manufacture them with the highest quality and cost-effectiveness. A new, fully coordinated turnkey system combines the specific requirements.

By Wolfgang Zangerle , Head of Business Development at Netstal

Due to the pandemic-related surge in demand, pharmaceutical and medtech manufacturers and suppliers are increasingly considering their own production of pipette tips. However, they often lack the technical background to build these themselves. Pipette tips for in-vitro diagnostics and other laboratory analysis must meet high quality standards and tight production tolerances. Specifically, the defined design tolerances must be met exactly in order to absorb the defined amount of liquid and transfer it without carryover.

In today’s automated liquid handling systems, capacitive liquid sensing is the predominant technology, which requires electrically conductive pipette tips. The perfect pipette tip (Fig. 1) is the result of an optimized production flow in which material, mold and production technology work together seamlessly.

Components of the production system

Complete production cells according to cGMP offer one option. The production centers can be continuously qualified and deliver both quality, production reliability and high volumes. Netstal demonstrated a reference system at K 2022: the all-electric machine of the ELION series has a clamping force of 120 tons in the medical version and works with an injection mold from Männer. The pipettes produced are gently and quickly removed from the mold by means of an automation system from MA micro automation and 100 percent optically inspected and dispensed in trays.

The production cell delivers fully tested “100 μl pipettes” from a 64-cavity mold in a very fast cycle time of 5.3 seconds. The production center requires only 25 m² of production area, which corresponds to a gross capacity of around 43,000 pipettes per hour, i.e. around 1720 pipettes per hour and square meter.

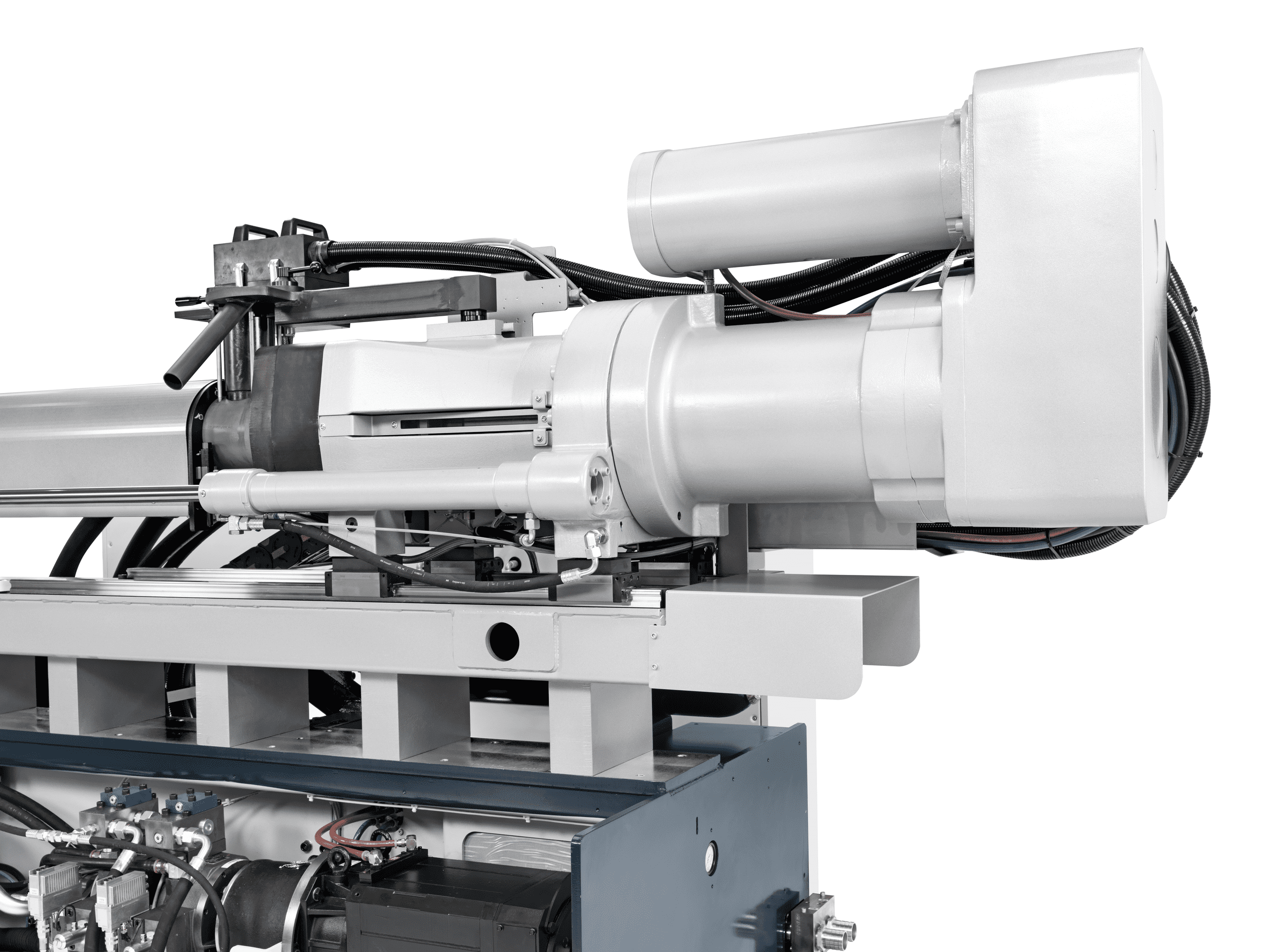

Requirements for the injection molding machine

The injection molding machine must fulfill specific tasks for pipette production. In material preparation, for example, an appropriate plasticization must be selected which does not contaminate the raw material, does not de-homogenize it or even degrades it impermissibly. If one of these factors is not controlled, the pipettes could fail in the automated diagnostic process, necessitate repetition or even lead to incorrect measurements.

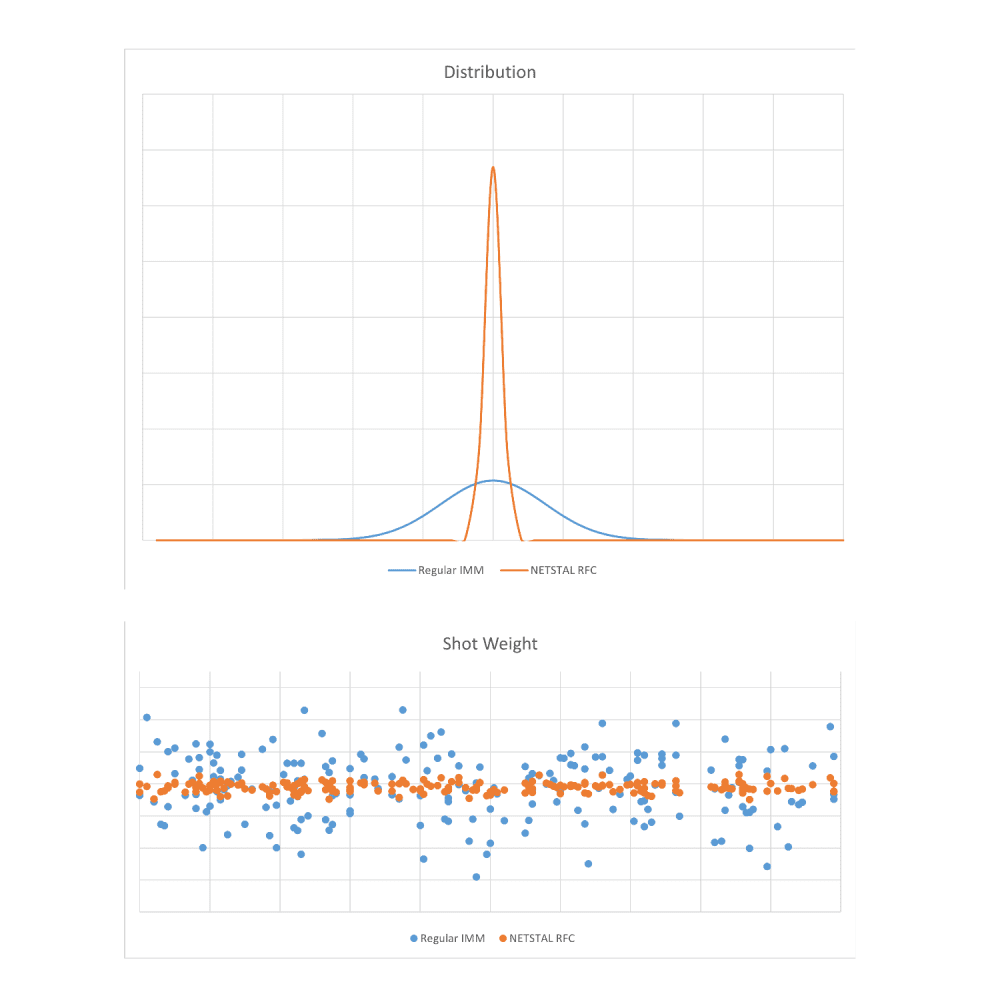

Netstal has devised a proprietary RFC control for accurate production results, which keeps the process of injection into the mold stable to produce high dimensional consistency at the pipettes. Figure 2 shows the difference in shot weight consistency for production with and without RFC control.

Precise mold

In addition to the high precision of Männer’s mold, the hot runner with its 64 nozzles must also be perfectly controlled and balanced in order to achieve symmetrical filling of the cavities and thus identical pipettes. This is ensured, among other things, by temperature sensors at all 64 hot runner nozzle tips, whose signals are passed on to the G24 Gammaflux controller. The controller records the values 20 per second and makes adjustments if they deviate 0.014°C from the setpoint.

HB-Therm temperature control units are used for high-precision temperature control of the entire mold and, in particular, of all 64 cavities. Supply temperature, pressure and flow are controlled. 16 flow sensors monitor the 64 cavities and the return heating. The result is identical caloric conditions for all cavities. Any deviation must be avoided, as dimensional changes on the pipettes lead to rejects during the subsequent optical inspection.

Connected via OPC UA

To ensure that the various components and systems act correctly in the network, they are networked by means of OPC UA interfaces. The operator of the production unit can control all system units via a central panel and be guided by SMART OPERATION, the automated start and stop program from Netstal. The mold is also an important element of production safety. Using predefined sequences, the control system can guide the operator through their operating operations. This is important when producing in a four-shift system.

As soon as the pipette tips have cooled down to removal temperature and the mold moves up, the modular automation system from MA micro automation with its high-speed linear axis goes into action. It removes the 64 pipettes within 1.07 seconds and transfers them on. Now a quality shot can be removed or the parts continue to the camera inspection.

Inspection and clean room

Visual inspection is just one of many inspections developed by MA micro automation for fully automated production lines for the manufacture of pipette tips. The 100% inspection monitors wobble/curvature of each pipette. 100% inspection of the pipette tip (frontal and radial) and the pipette holder (frontal) can be additionally applied in a controlled manner to make absolutely sure that no pipettes are placed in racks that do not exactly meet the defined part accuracy. During the inspection, up to 48 measurements/second are performed, and this in a cGMP qualified state. After successful inspection, the pipettes are filled into appropriate racks, which are injection molded or thermoformed, or into bags, depending on the customer’s desired configuration.

Pipette production is subject to the requirements of a controlled environment, mostly cleanroom ISO 8 and GMP C. A qualification of the turnkey plant according to cGMP and the fulfillment of the corresponding clean room requirements is therefore mandatory, here the calibration of the machine plays a decisive role. Netstal is certified according to ISO 17025 and is also allowed to perform recalibrations on production equipment at the customer’s site to ensure the production consistency and validity of the machine.

First turnkey production

Until now, there has been no completely coordinated turnkey plant for pipette tips on the market. The novel production cell (Fig. 3) is an impressive result for hand-in-hand cooperation between the manufacturer and all suppliers involved. This makes it very easy for the customer to configure his own system. The time-consuming and cost-intensive trial-and-error phase is skipped; after successfully completed acceptance tests, the pipette cell is directly “ready to produce” as a system. In addition to a high level of safety when taking the step into the product segment, the new production island offers maximum efficiency and the highest output in series production.

Highest precision and reproducibility under all conditions

The Netstal brand has always stood for high performance but also for maximum precision and reproducibility. The demands from the industry on the quality and consistency of the produced components are constantly increasing. The unique and highly accurate RFC injection control system from Netstal plays a decisive role precisely in this context. Thanks to stable mechanical construction, highly accurate measurement technology and sophisticated control technology, the injection units from Netstal achieve an extremely high shot weight consistency. This means that the user can fully rely on his production.

In addition to the high demands on precision and reproducibility, productivity is constantly increasing. Cycle times are decreasing and the number of cavities is increasing. An example of this is the production of pipette tips. Today, high-performance systems produce on 64-cavity molds with a cycle time of less than 5s.Netstal already proved at the K show 2016 that 128 cavities are also possible:https://www.youtube.com/watch?v=fZ19sM7-KQw&ab_channel=NetstalIn terms of quality and reproducibility, the control of the injection process plays a central role. Already when filling the cavities, it is decided whether the parts will be within the set tolerance or not.The developers at Netstal are aware of this fact and have always placed a strong focus on injection control. From the machine’s point of view, the control quality of the injection process is based on the following three features:

- Stable design and the most direct power transmission possible from the drive to the screw tip

- Highly sensitive sensors and high sampling rates

- Powerful control algorithms and real-time capable computer systems

Netstal RFC (responsive filling control)

The control of the injection process includes two phases:

- Injection phase

- Holding pressure phase

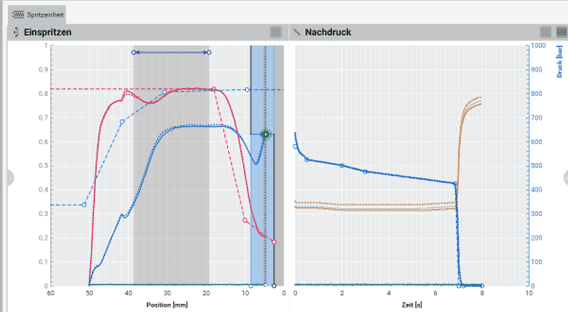

During the injection phase, the injection speed is tracked as the leading controlled variable. During this phase, the specified velocity profile is readjusted as accurately as possible and without delay. This can be seen clearly in the following screenshot in the diagram on the left.

Diagram: Injection phase (left) and holding pressure phase (right)

As soon as the cavities are filled volumetrically, the controller switches to the holding pressure phase and here the injection force is tracked as the leading controlled variable. This can be seen in the right diagram of the screenshot above.

The decisive factor is now how and at which screw position the switchover from speed to pressure control takes place. This is commonly referred to as v/P changeover.

Displacement or pressure dependent?

In practice, changeover is usually position-dependent. This means that the changeover takes place at a certain screw position, irrespective of the current quality of the melt. Due to various external influences, the melt quality can be subject to fluctuations, which are subsequently reflected in a greater scattering of the shot weight and thus of the component quality.

However, pressure-dependent changeover is particularly advantageous, especially for short injection times and fast cycles. Here, the changeover process is determined by the melt pressure. This strategy has the advantage that fluctuations in melt quality are automatically compensated. This leads to a higher shot weight consistency and thus to better quality reproducibility.

The pressure-based v/P switchover RFC detects very precisely when the mold cavities are filled volumetrically and the optimum time for initiating the holding pressure phase has been reached. This leads to a high shot weight consistency by automatically compensating for external environmental influences such as material fluctuations and the closing behavior of the non-return valve.

The role of the non-return valve

As a mechanical element at the screw tip, the non-return valve plays an important role in the injection process. Its correct function is a mandatory prerequisite for a controlled and cleanly controllable injection process. On the one hand, it must be ensured that the non-return valve seals well when closed and that no disturbing leakage losses occur, and on the other hand, the closing behavior is also of great importance. For these reasons, regular inspection and maintenance of the non-return valve is highly recommended.

To positively influence the closing behavior, the highly flexible functionality of the aXos control system can be used. Namely, if the metering process is designed in such a way that the back pressure is maintained at the end of the metering time, the non-return valve is actively closed after metering. The subsequent injection process can then already be started with the non-return valve closed, which further improves shot weight consistency. As of control version aXos 8.5.1, the user is additionally supported in this setting with a new synchronization mechanism, which significantly simplifies the setting process.

The result can be measured.

The precision and reproducibility can be demonstrated using the example of a test series on the “Connector” component.

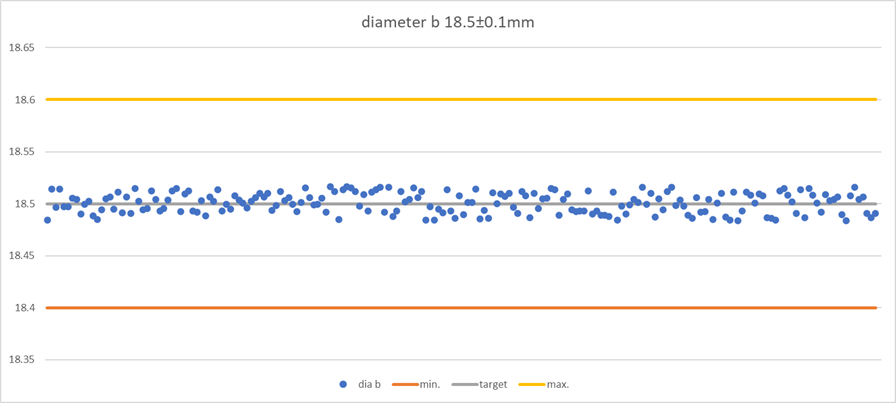

Diagram: Measurement series “Connector”

The diameter b was measured for 200 consecutive cycles. The mean value of the measurements was 18.499mm. The values scattered minimally by 0.008mm which, with the set tolerance of 18.5 +/- 0.0.1 mm, results in an excellent CpK value of 1.96 .

Quality through process reliability

Achieving high and, above all, consistent quality requires that the production process is 100% under control. The production system must be able to compensate for external influencing factors and ensure a sufficiently large process window with the available performance. Netstal machines provide the basic prerequisites for this right from the start: Stable construction, high-precision sensor technology and sophisticated control technology.

So when it comes to high-precision and reproducible production, it pays to choose Netstal.