Netstal PET system solutions offer you premium quality, minimum production costs and an optimal eco balance.

Your benefits

Sustainably increase availability

Our recipe to successfully increase your system availability: Reliable technology that manufactures at maximum speed with peak precision. In the unlikely event of a problem, you can always fall back on our global service network. Being localized, we can provide support either on-site or online.

System solutions

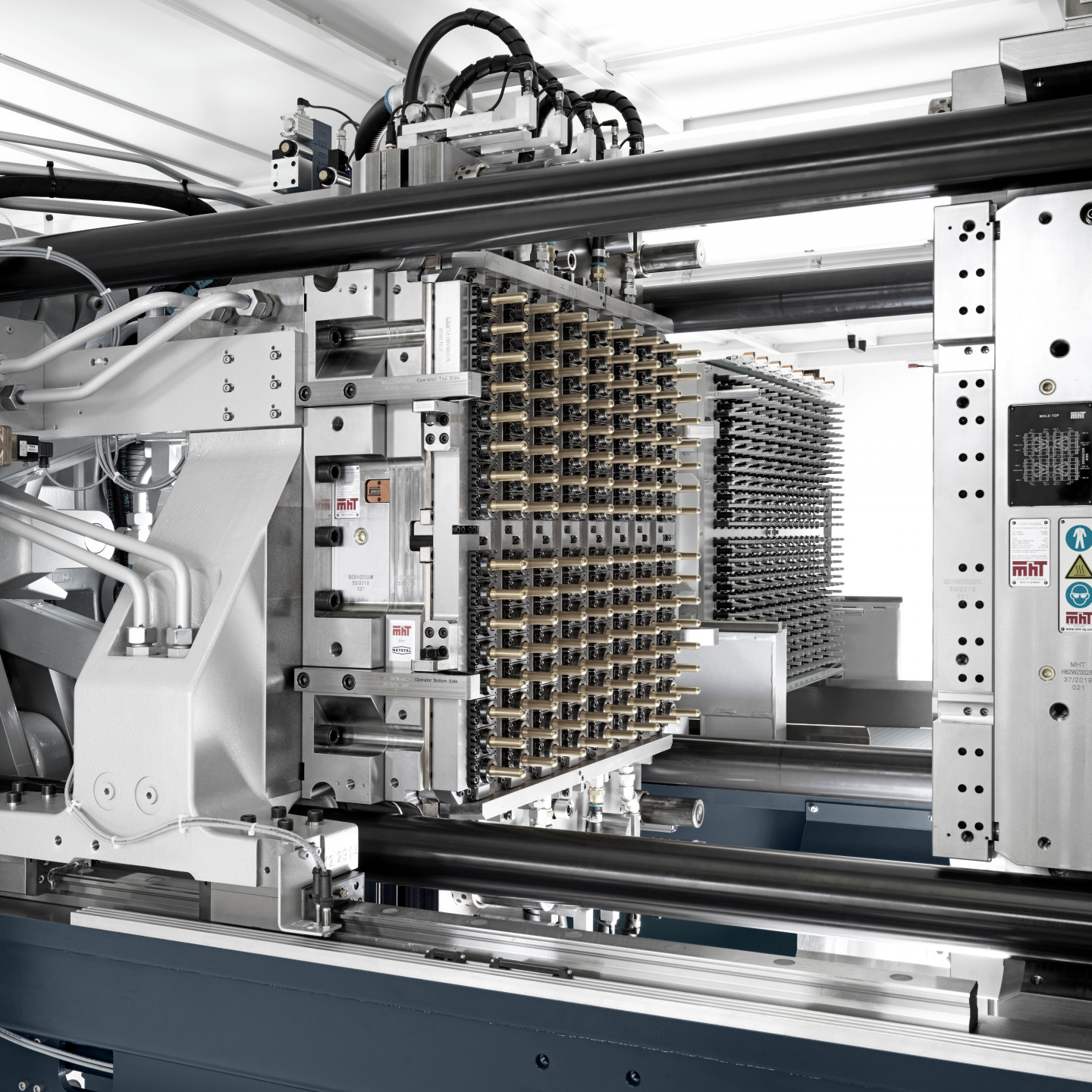

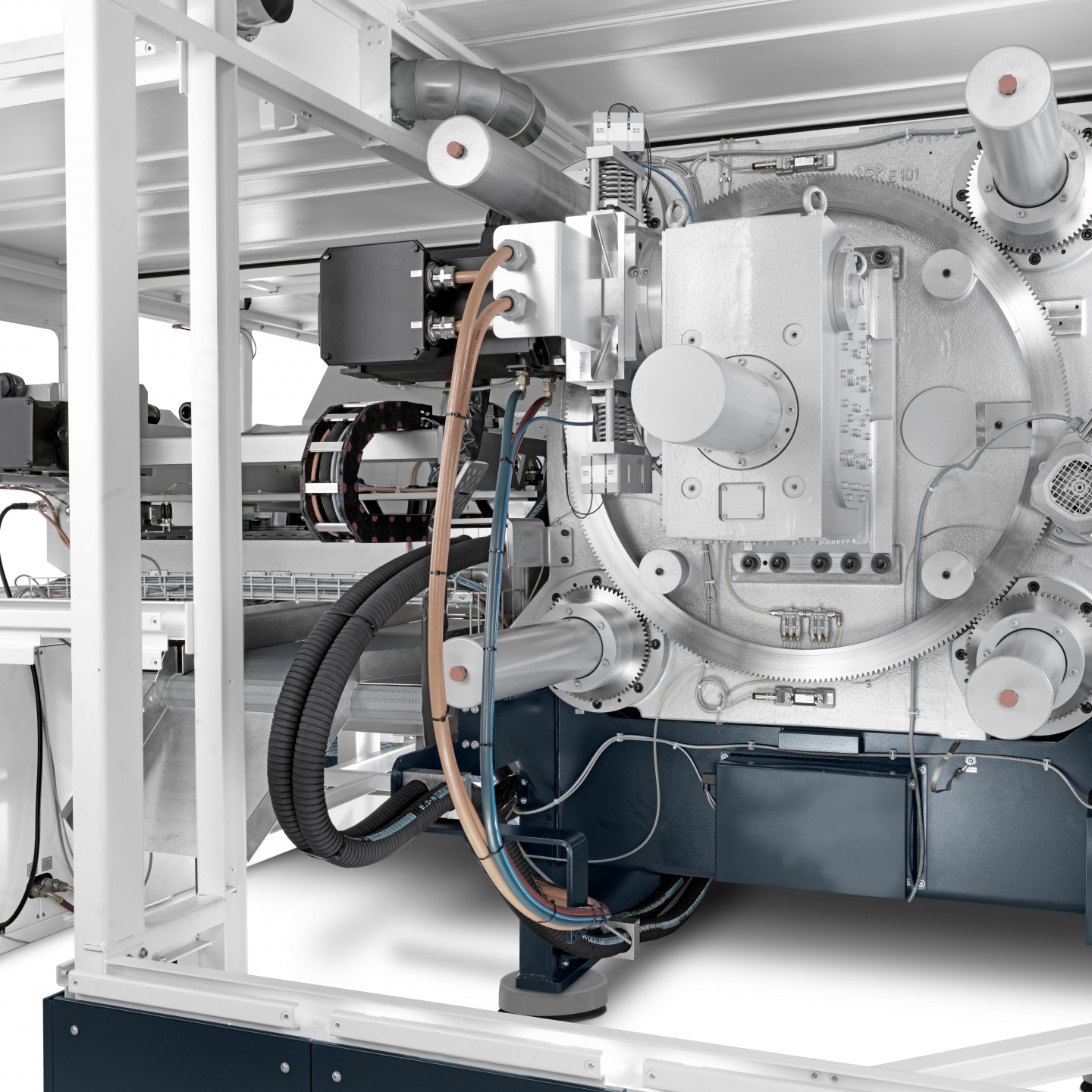

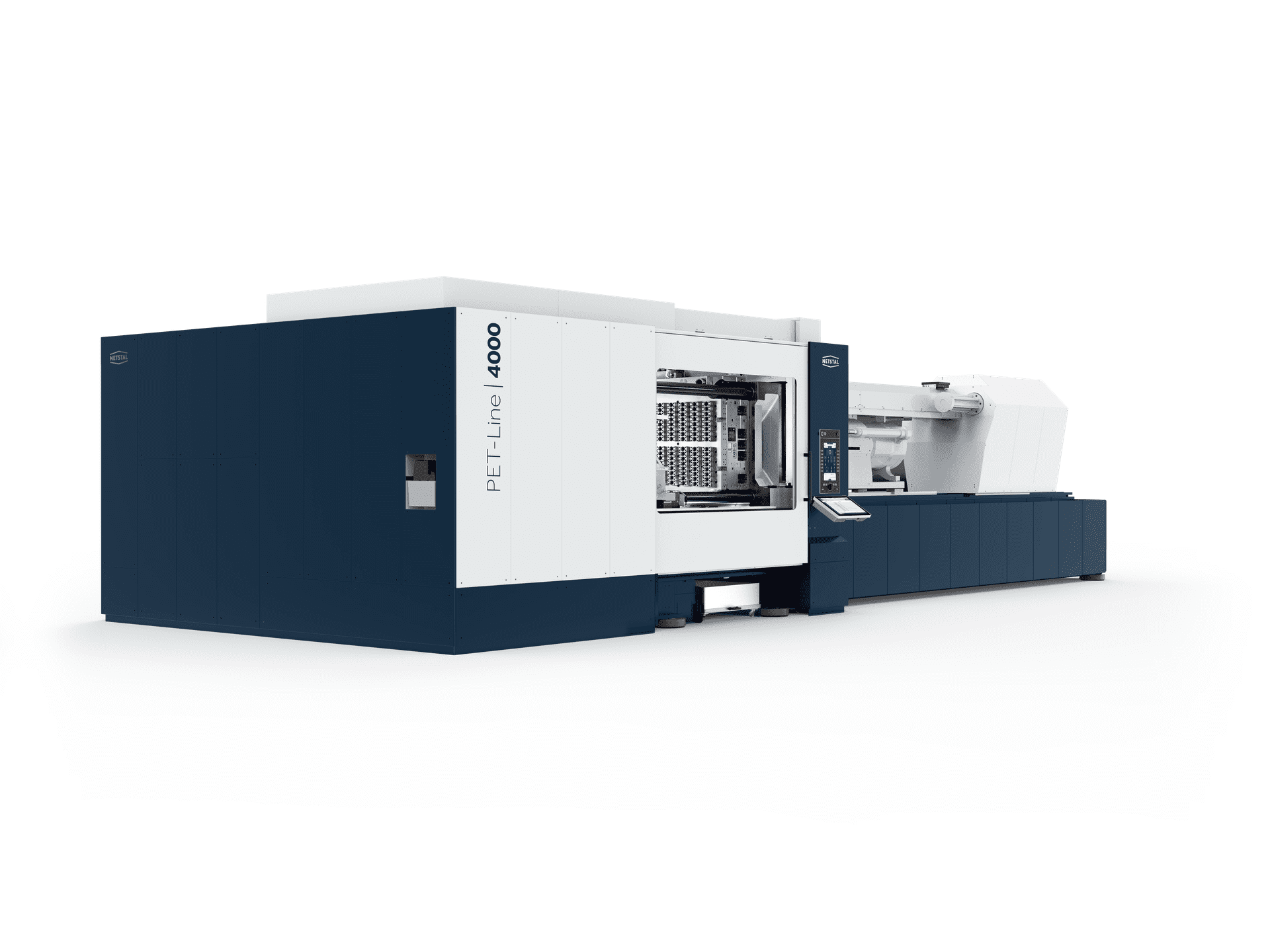

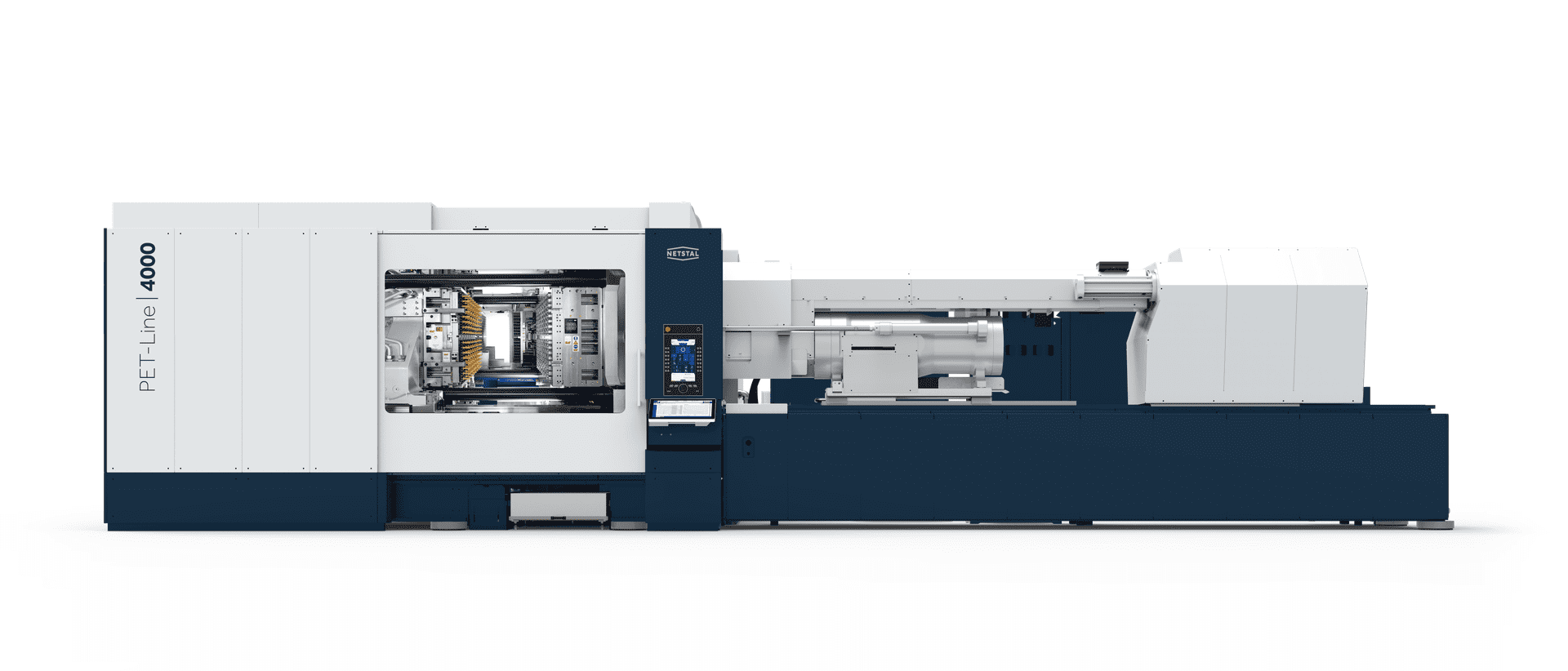

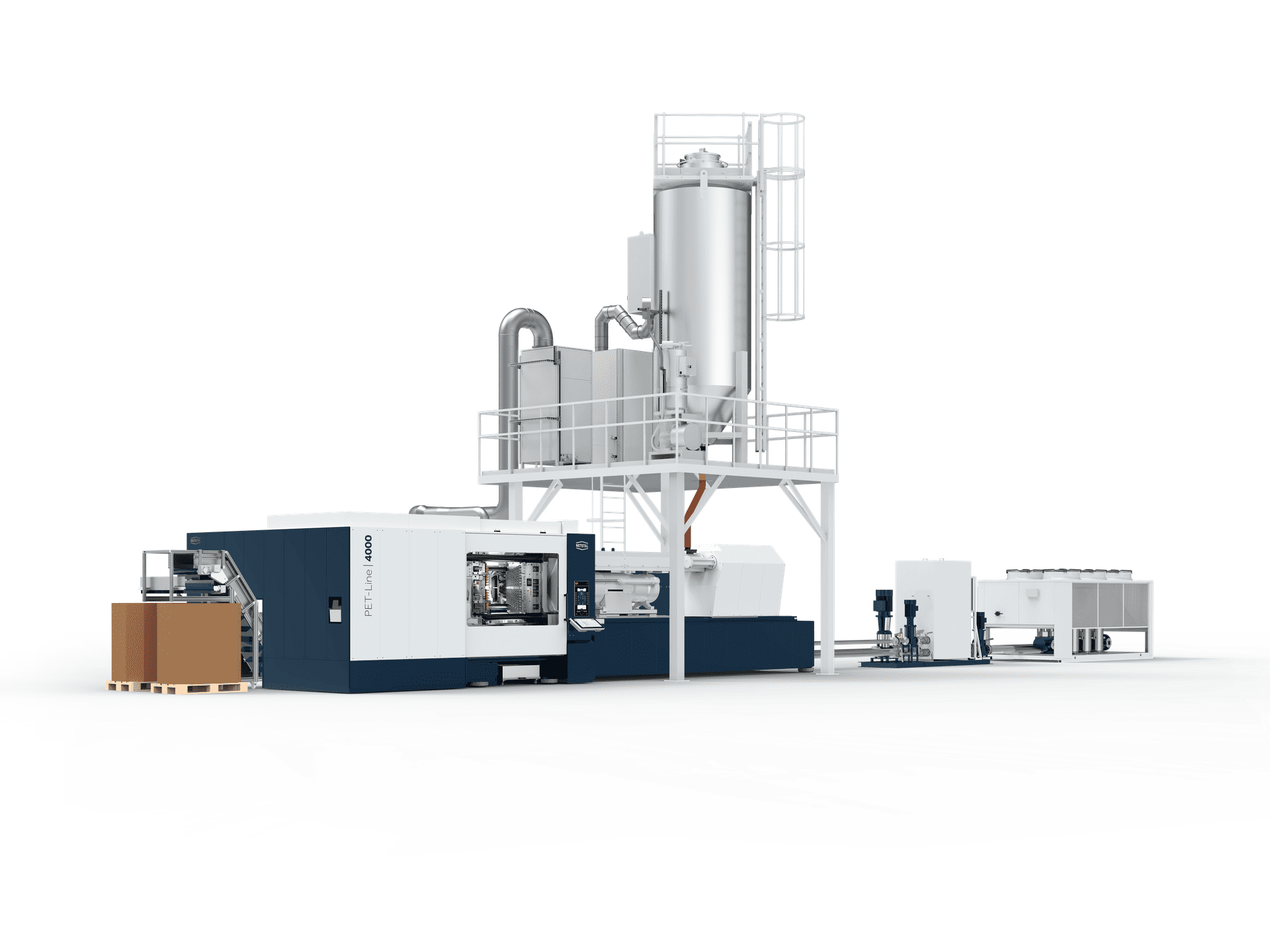

Using the PET-Line as a machine basis, you hold the key to the most highly productive preform systems. When designing a complete turnkey system, we collaborate on your behalf with leading industry and market partners.

Netstal provides you with everything from a single source; the machine, mold, hot runners, post-mold cooling stations, material dryers, dry air curtain units, chillers and other peripheral equipment – not to mention our all encompassing preform expertise. The machines and complete systems are configurable to a maximum of 192 cavities.

Process chain

Project idea

- Product idea (specific idea of molded part)

- Product concept

- Product specification

Concept study

- Parts concept

- Part optimization weight, functionality, design, decoration

- Technology evaluation (process)

- Material evaluation/definition

Project work

- System definition/design

- Machine definition/design

- Tool concept and planning

- Machine supply and infrastructure definition

- Planning of primary periphery (material preparation and supply)

- Planning of secondary periphery (removal and downstream equipment / Q control / packaging station)

- Cost simulation / optimization

Implementation

- Detailed design of all plant components

- Procurement and production

System installation and factory acceptance test (FAT)

- Initial installation

- Function test

- Quality and performance testing

- Initial customer training (all components)

- System acceptance based on contract data

Installation at customer site

- Installation and commissioning

- Training on site

- Handover and production start

Process and production support

- Process optimization with regard to quality, efficiency, cycle time, etc.

- Advice on preventive maintenance

- Follow-up checks of process stability

- Service and maintenance work

- Machine calibration

Process chain

❶ Project idea

- Product idea (specific idea of molded part)

- Product concept

- Product specification

❷ Concept study

- Parts concept

- Part optimization weight, functionality, design, decoration

- Technology evaluation (process)

- Material evaluation/definition

❸ Project work

- System definition/design

- Machine definition/design

- Tool concept and planning

- Machine supply and infrastructure definition

- Planning of primary periphery (material preparation and supply)

- Planning of secondary periphery (removal and downstream equipment / Q control / packaging station)

- Cost simulation / optimization

❹ Implementation

- Detailed design of all plant components

- Procurement and production

❺ System installation and factory acceptance test (FAT)

- Initial installation

- Function test

- Quality and performance testing

- Initial customer training (all components)

- System acceptance based on contract data

❻ Installation at customer site

- Installation and commissioning

- Training on site

- Handover and production start

❼ Process and production support

- Process optimization with regard to quality, efficiency, cycle time, etc.

- Advice on preventive maintenance

- Follow-up checks of process stability

- Service and maintenance work

- Machine calibration

Please accept YouTube cookies to play this video. By accepting you will be accessing content from YouTube, a service provided by an external third party.

If you accept this notice, your choice will be saved and the page will refresh.

Blog posts about Preform injection molding

Life Cycle Services

Life CycleServices

Start-up phase

We provide support from the very outset with machine installation and commissioning all the way through to staff training, even in the project planning stage if required.

An ideal start creates a firm basis for your success. You have our full support from the very beginning. Our engineers guide you from installation right through to successful initial production. We provide support with machine installation and commissioning all the way through to staff training, even in the project planning stage if required.

Installation

Our highly motivated team will ensure the quick and professional installation of your system.

Training

Well-trained operators are the cornerstone of successful system utilization.

Remote Support

Our state-of-the-art remote maintenance solution provides support as early as commissioning and the ramp-up phase.

Commissioning

Our specialists install your system on site, train your operators and carry out trial and acceptance runs with them.

Spare part packages

Even before your system is up and running, we coordinate customized spare parts packages for your specific application.

Training courses

Well-trained operators ensure a high level of production and machine safety. Netstal offers a comprehensive training program at the company training center as well as customized training at your location.

Troubleshooting

A functional fault may result in a loss of capacity, lower product quality and reduced productivity. Our optimally trained technicians and tightly woven global service network enable us to provide fast rectification.

Preventive maintenance

Preventative maintenance largely averts unplanned and expensive downtime.

Remote Support

Our state-of-the-art teleservice allows us to directly access your system for swift troubleshooting and support.

Hotline

If technical problems or machine failures occur, a quick and competent solution is paramount. We support you with our technical know-how and commitment to quickly get your system up and running again.

Machine relocation

During the long service life of a system it may need to be relocated from one production site to another. Our service specialists provide customized services from a single source ranging from internal machine relocation to complex plant relocation.

Spare parts service

Ensuring our customers obtain original spare parts as quickly as possible when needed is the number one priority of our spare parts department. Our proactive spare parts management advises and helps select the requisite spare and wear parts.

Maintenance and repairs

Only a regularly serviced system will enable you to attain a reliable level of production when running at capacity. Regular maintenance preserves the value of the system and prevents expensive machine downtime. Netstal offers you the commensurate maintenance programs.

Inspection

To err on the side of caution, have your system inspected by our specialists. Using the requisite special tools and measuring equipment, we can quickly analyze the condition of your system and promptly carry out any necessary maintenance work. Using a checklist, we examine the system’s electrical, hydraulic and mechanical components as well as its safety technology. The resulting reports provide details of any need for spare parts or further action.

Application consulting

Need support for your applications or processes? Draw on the experience and advice of our process engineers who would be delighted to help.

Warranty

In the case of pending problems or failures, we provide the necessary parts or support quickly and unbureaucratically.

Life CycleServices

Utilization phase

The minute you start using your system, our experienced service team are on hand to provide a broad range of diverse services.

Our fast and extremely competent service ensures production runs smoothly and efficiently. The minute you start using your machine and system, our experienced service team are on hand to provide a broad range of diverse services. As a consequence, the availability of your machines and system are safeguarded throughout the production process.

Life CycleServices

Optimization

So you always efficiently utilize your system and can met new requirements, we offer substantiated specialist know-how ranging from technical consulting and individual component optimization, right through to preventative maintenance measures.

Our aim is to ensure your system and employees remain at the cutting edge of technology. New technologies can be integrated into existing systems, allowing you to keep up with the very latest innovations. Following a qualified technical conversion, we provide your staff with the commensurate further training.

Retrofit work

Retrofitting is often necessary to meet new requirements. In this context, we supply ready-to-install turnkey solutions, including all the commensurate services.

Process consulting

Should requirements change in terms of materials, tools and processes, our experienced process engineers will support you with the implementation of any necessary measures.

Modernization

Newly developed technologies can be integrated to increase the productivity of your system. These include our state-of-the-art controller and newly developed machine components.

Energy consulting

Increasing energy costs make analysis of your system a sensible investment and one we would be delighted to advise you on: Whether that involves optimally adjusting drive motors or thermal insulation of the heater bands.

General overhaul

You are happy with the system and would like to extend its service life. Plan a general overhaul of your system with us and continue to get the best out of it.

Used Machines

We offer cost-effective solutions and comprehensive benefits in terms of purchasing, selling or leasing a used system.

Life CycleServices

Extend the life cycle or phase out?

Has your system seen better days? Not a problem! We can make your system fit for the future through a state-of-the-art upgrade or general overhaul.

After performing admirably for many a year, although your system is past its prime and in need of commensurate repair, you would still like to keep using it. We would be delighted to help with advice on practical measures and investments. With a general overhaul, we can make your system fit for the future.