We think from our customers' perspective

As the world's leading Swiss manufacturer of injection molding machines and system solutions for plastics processing, Netstal Maschinen AG is also intensively engaged with digitalization and sustainability. In this interview, Renzo Davatz explains what this means for the further development of technology and what role leadership plays in volatile times for the future of the company and Switzerland as a manufacturing location.

Mr. Davatz, how has your core business, the manufacture of injection molding machines for plastics, changed in recent years?

The most significant change is probably the pressure from Chinese manufacturers, who have caught up technologically and are pushing into Western markets with highly aggressive pricing. This combination of increasing technical competitiveness and enormous price aggressiveness is also changing the business for Western injection molding machine manufacturers.

Which target markets are particularly important to you?

Europe has historically been an important market for us. We are now well established there. We expect the greatest growth to come from the US, which is a very exciting market. At the same time, we are also active in Asia. For the past two to three years, we have also been very successful in India, which is also developing into an exciting market for us.

The packaging of food and the manufacture of medical consumables are fundamental aspects of our everyday lives. Does that mean we have a special responsibility?

The greatest responsibility that I, or we, feel is to live up to the Netstal brand promise. Netstal is known for maximum performance and optimum production efficiency. We want to live up to this promise not only with performance and quality at delivery or in the first year of operation, but throughout the entire life cycle of a machine. With comprehensive service for spare parts, retrofits, and optimizations, we want to maintain high production efficiency and availability of the systems throughout their entire service life. Of course, there are specific requirements in the food and medical sectors regarding cleanliness, traceability, and documentation, to which we have always been committed.

Are there any new trends in plastics processing that will shape the coming years?

In the areas of application in which we operate, there are not as many new plastic materials as there are in the automotive industry, for example. However, there is a trend towards using PET, the material used to make PET bottles, for other applications as well. For example, caps, which have traditionally been made from HDPE, are now also to be made from PET, even though this poses a major technical challenge. This would further facilitate the recycling of PET bottles, for which a closed loop has already been established in Switzerland and Germany. There are also attempts to produce thin-walled and food packaging from PET. In addition, there are bio-based plastics, which have not yet become widely accepted because they are too expensive in large quantities. Technically, this already works, but it does not yet make economic sense.

"There are product managers, salespeople, and application engineers for each area. And they think strictly within their field of application and work on optimizations for these applications."

To what extent are new developments determined by digitalization and sustainability?

Whereas in the past it was all about the physical product, namely the machine, today it is increasingly about being able to offer customers an integrated, networked, and therefore autonomous production cell. This should be as easy to operate as possible, deliver high output, and offer correspondingly large process windows. When it comes to sustainability, two aspects are now crucial. The machine itself should consume less and less energy. This means that hydraulic axes are increasingly being replaced by electric axes. Secondly, it is important that the machines can process materials such as rPET, which means recycled PET, without any problems.

So you always have to think from the perspective of customers who want to manufacture or package their products even better or more efficiently?

This customer-oriented approach is very important to us. We have four application units: PET preforms, which are preforms for subsequent PET bottles, closures, medical technology applications, and thin-walled packaging, for example, for ice cream, butter, or margarine. There are product managers, sales representatives, and application engineers for each area. They think strictly within their field of application and work on optimizations for these applications.

What sets Netstal apart from its international competitors?

We are very focused on our four areas of application and do nothing else. If you ask me about our USP, I would say that Netstal stands for exceptional production efficiency. Our machines may not be the cheapest to purchase, but they enable you to manufacture your product at the lowest possible cost.

What does leadership mean in the face of global crises, regional sanctions, or regulations?

In my opinion, all the volatility and uncertainty make the job more exciting than ever. I believe the challenge is that a good leader must be able to set a direction even when not all the answers are available. It is important to communicate honestly about what is known and what is not. And to set clear priorities that help the team remain capable of acting despite uncertainties. Good leadership in volatile times means having inner stability while everything around you is in flux.

What makes Netstal stand out as an employer?

I would highlight two points. First, despite, or perhaps even because of, a very challenging environment in the industry, we have a team that has developed a special corporate culture and is enthusiastic about our customers and their products. A genuine Netstal spirit, if I may say so. The second point is our international environment. With a technologically sophisticated product and an export quota of 95 percent, the company can naturally offer exciting and very diverse careers as well as opportunities for further development. It has been exciting from the very beginning. I was able to experience this myself, as I started as an apprentice in this company.

The interview was conducted for the new issue of “20 CEOs. 20 OPINIONS” in Handelszeitung, published on December 24, 2025. We translated it to make it available for our international followers. Click on the following link to view the entire issue (German).

New: Adaptive system pressure reduction in PET applications

With the adaptive system pressure reduction function, users of the Elion and Elios series have already been achieving considerable energy savings since 2023. The option is now also available for PET-Line.

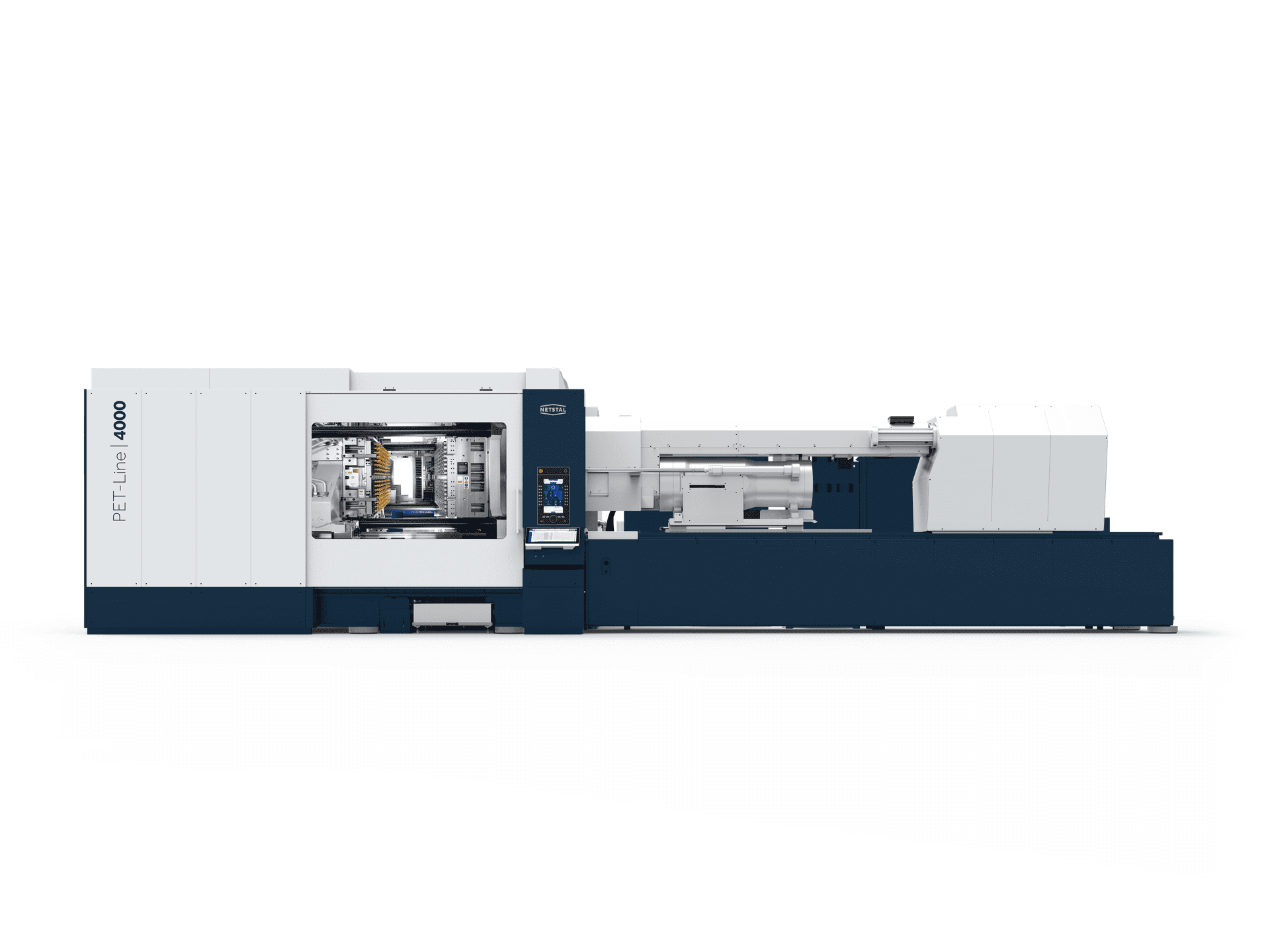

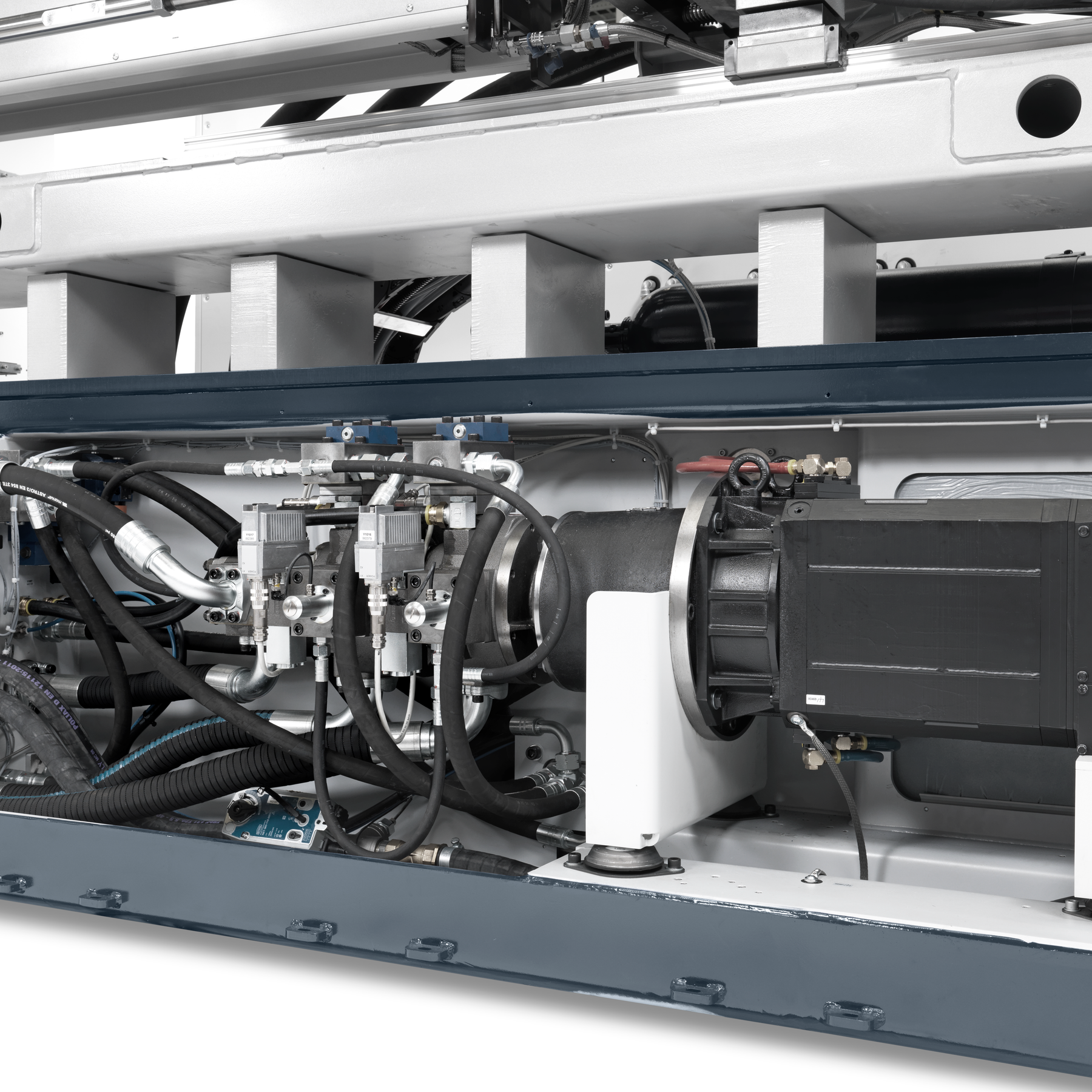

Since its market launch in 2020, the PET Line with side entry has been considered the most modern and energy-efficient preform injection molding system on the market. With the adaptive system pressure reduction, which is now also available for the PET-Line, Netstal is further increasing efficiency. With active system pressure reduction, the hydraulic pressure is lowered to the optimum point. Only as much pressure is generated as is required.

Please accept YouTube cookies to play this video. By accepting you will be accessing content from YouTube, a service provided by an external third party.

If you accept this notice, your choice will be saved and the page will refresh.

The video illustrates how adaptive system pressure reduction works.

Leading energy efficiency at maximum productivity

The potential is enormous: depending on the application profile, you can save five-figure energy costs per year with the system pressure reduction. The significantly reduced consumption also lowers the CO2 footprint of your entire production. Most importantly, the cycle time and injection performance are not affected. The PET-Line produces the same output and consistent quality with lower power consumption.

Find out more at drinktec

At our live exhibit at drinktec, we will be happy to advise you personally on adaptive system pressure reduction and the many other benefits of the PET-Line that will make your day-to-day production easier. At our stand, you can experience a PET-Line 4000 of the latest generation. It produces ultra-light 6.9 g preforms with a 25/22 neck thread. The visit is worthwhile, you will find us from September 15 – 19 at the Munich trade fair, Hall C6, Stand 361.

Fair information and appointments

Visit Netstal at drinktec 2025 and experience the next generation PET-Line

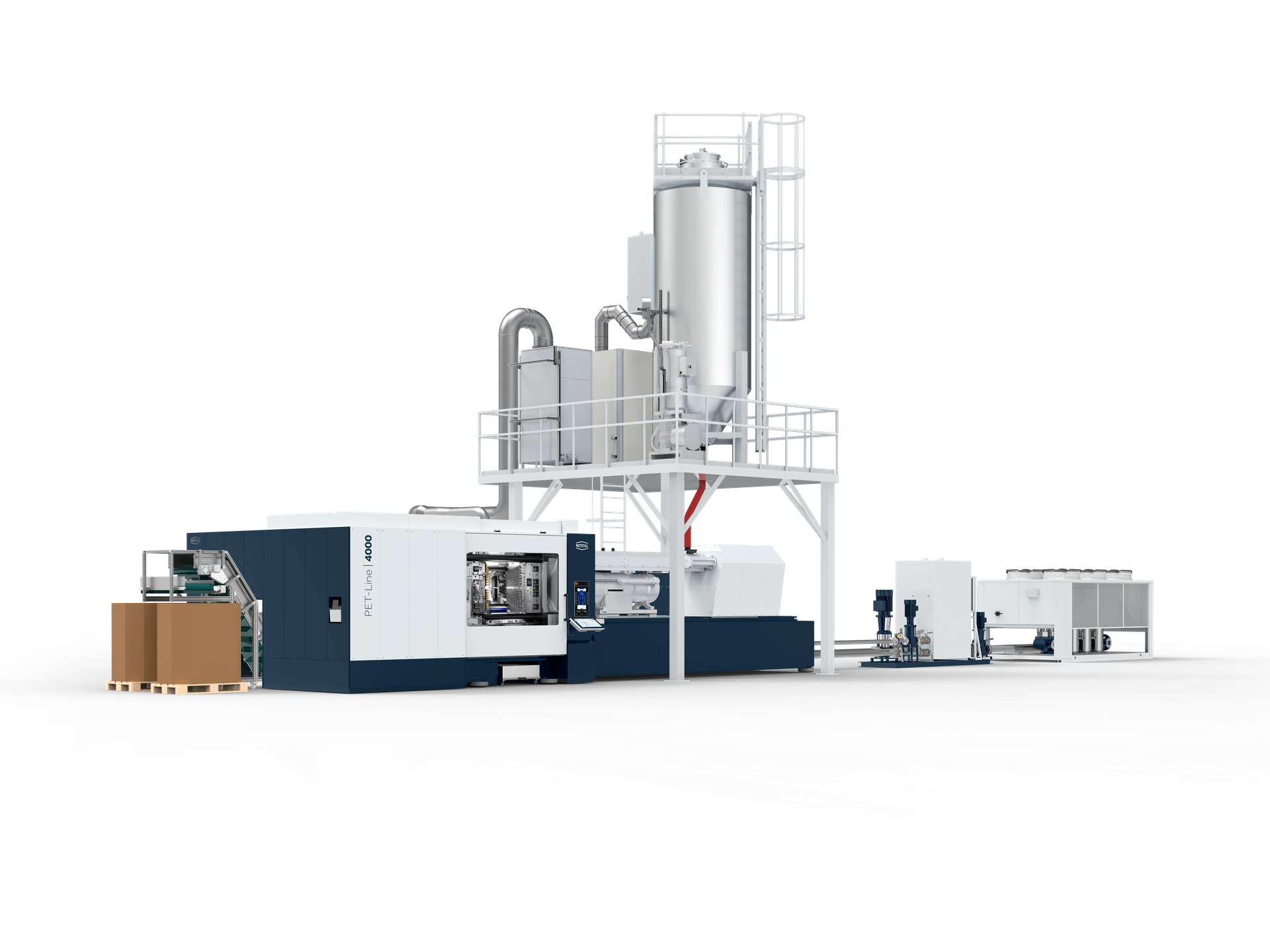

Efficient and resource-saving: Netstal will be presenting a new generation of PET-Line for the first time at drinktec (September 15–19, 2025, in Munich). With smart innovations, the system not only increases production efficiency but also improves user comfort.

At the Netstal booth in Hall C6, a PET Line 4000 is producing ultra-light 6.9 g preforms with 25/22 threads.

Commitment to sustainability: After drinktec, the preforms will not simply be disposed of, but returned to the PET recycling loop.

These highlights await you:

- Maximum performance potential: A 144-cavity mold from MHT with integrated self-cleaning function is used. The fast cycle time of 4.8 seconds produces around 108,000 preforms per hour. A 160-cavity option further increases the potential with a clamping force of 400 tons. The largest PET-Line 5000 is available for maximum output. With a clamping force of 500 tons, molds with up to 192 cavities can be used.

- Leading energy efficiency: The PET line uses kinetic energy recovery in the clamping unit and post-cooling station. With top ratings, the PET line stands out as one of the most energy-efficient PET systems on the market. A new feature is the optional system pressure reduction: It lowers the hydraulic pressure and keeps it at the optimum point. Depending on the application profile, additional annual energy costs in the five-digit range can be saved.

- Focus on the highest quality: The fully integrated Vision Control System checks the preforms in real time, detects possible process errors at an early stage, and documents everything automatically. With the new Quality Shot, random samples of a complete shot can also be taken at the touch of a button.

- Redesigned ease of use: The Smart Operation feature integrated into the Axos control system makes operation during shift work particularly safe and intuitive. With the new Task Quick Mold Change, even low-skilled personnel can now change molds quickly and safely. Tasks are graphically designed application aids that guide users step by step through more complex tasks. Additional tasks are already in the planning stage.

- Connectivity for maximum control: The PET-Line offers all modern interfaces based on OPC-UA for networking with central control systems and various peripheral components.

The PET-Line sets new standards in terms of performance, energy efficiency, quality assurance and user-friendliness. So it’s well worth a visit from September 15–19 at drinktec 2025, Hall C6, Stand 361.

Trade fair information and appointments

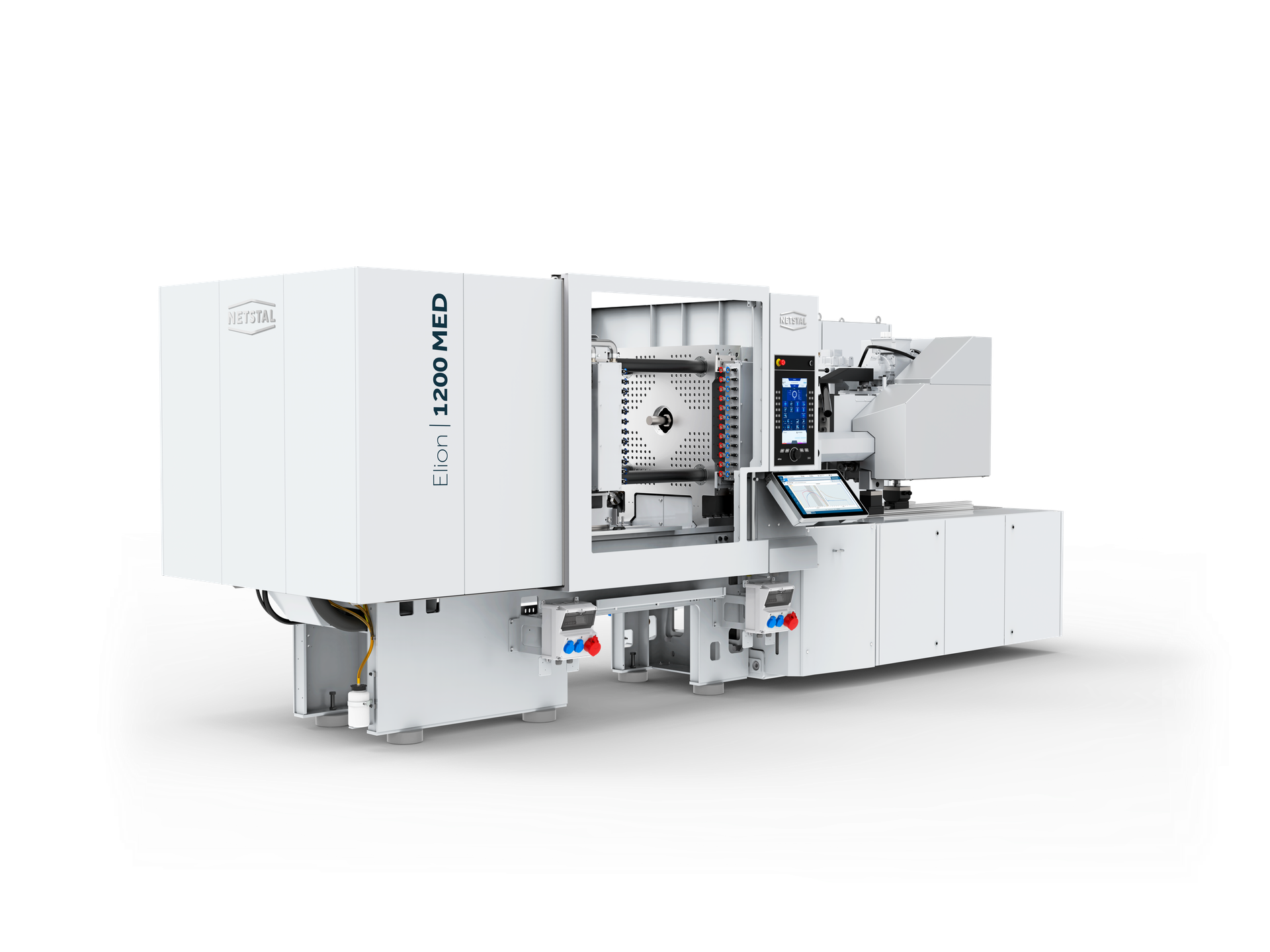

Next machine generation: Experience the new Elion MED at K 2025

Do you manufacture medical technology parts from plastic and are you enthusiastic about innovative injection molding technology? Then you should plan a visit to Netstal at K 2025. In our booth D24 in hall 15, we will be presenting the latest generation of the Elion MED with a shortened design, optimized toggle lever geometry and a new injection gearbox. With the new Elion MED, you can produce on a smaller footprint with increased efficiency. We call this "the evolution of efficiency".

These highlights await you:

- High performance in a small space: We have consistently optimized all modules for a compact footprint. The result is a significantly shorter machine that offers outstanding performance and great flexibility for a wide range of applications with identical clamping force.

- Leading precision: High-precision sensors with an extremely high 2 kHz sampling rate enable unmatched precision and reproducibility. The newly revised quality monitoring system ensures seamless monitoring and assurance of production quality.

- Unmatched reliability: Netstal machines are particularly durable. With the new Elion, we have further developed proven concepts. The machine is extremely solidly engineered. This enables us to meet your high requirements so that you can produce continuously for many years without any loss of performance.

- Maximum efficiency: The servo drives we use offer you the best energy efficiency. With the newly designed servo-hydraulic direct drive for the aggregate movement and the application of the contact force, we have once again significantly increased the energy efficiency of the Elion.

- Clean room compatible: Thanks to fully encapsulated and water-cooled drive motors and hermetically sealed control cabinets, the new Elion operates with virtually no emissions. We have designed the entire machine with its new protective housing for optimal cleaning. The Elion MED can be used in clean rooms up to class 7 as standard. Higher clean room classes are also possible with additional equipment options.

- Open connectivity: The new Elion offers all modern interfaces based on OPC-UA for networking with central control systems and various peripheral components. Thanks to HTML 5 integration, even more complex system components can be easily integrated into the machine control system.

Live production at the Netstal booth:

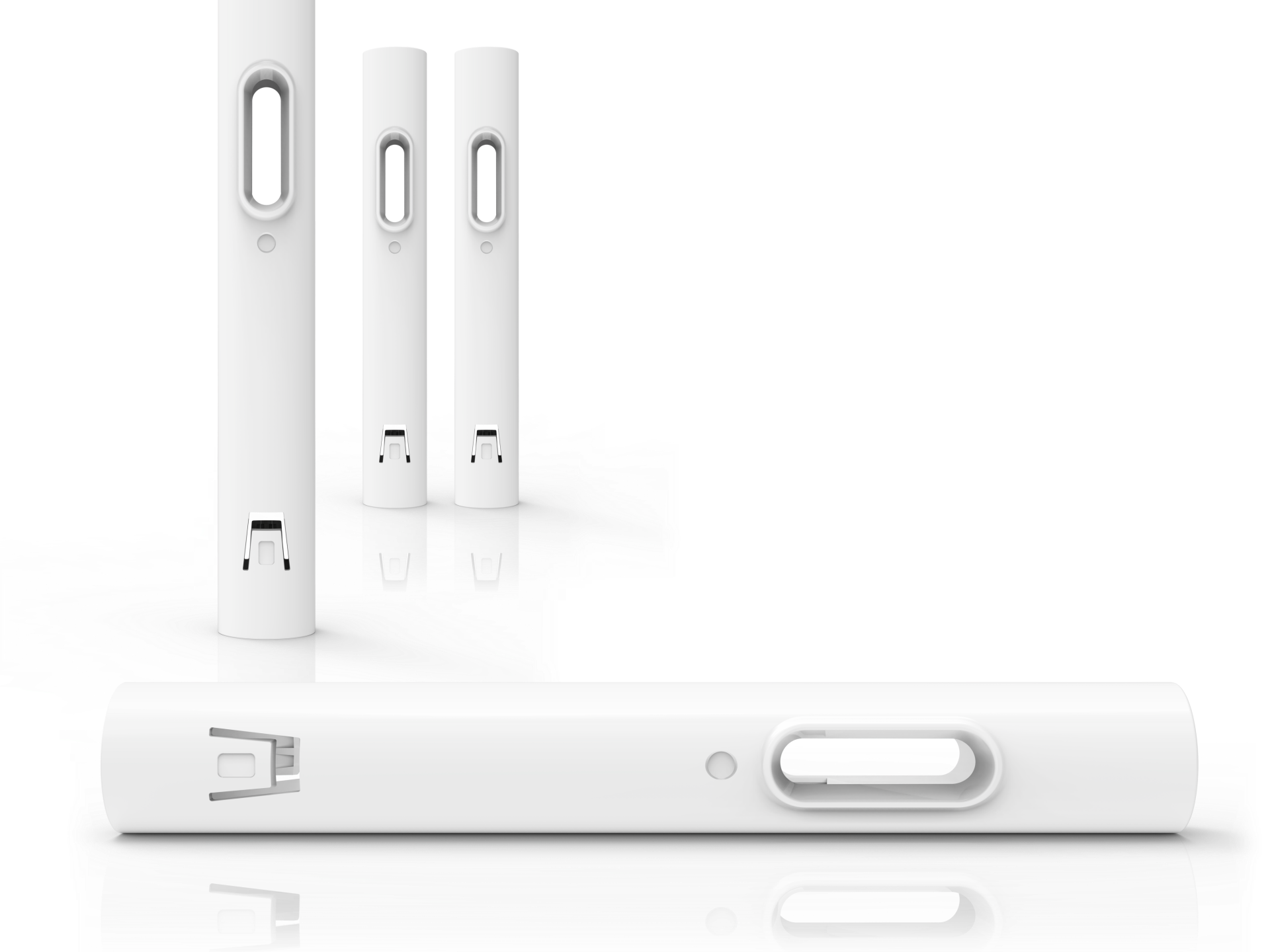

For the market launch, we will be demonstrating the new Elion MED in action at K 2025 in Hall 15: On the 1200 kN machine, which is optimized for clean rooms, an autoinjector housing is produced in a cycle time of approx. 12 seconds, using an innovative 4-cavity mold from Zahoransky.

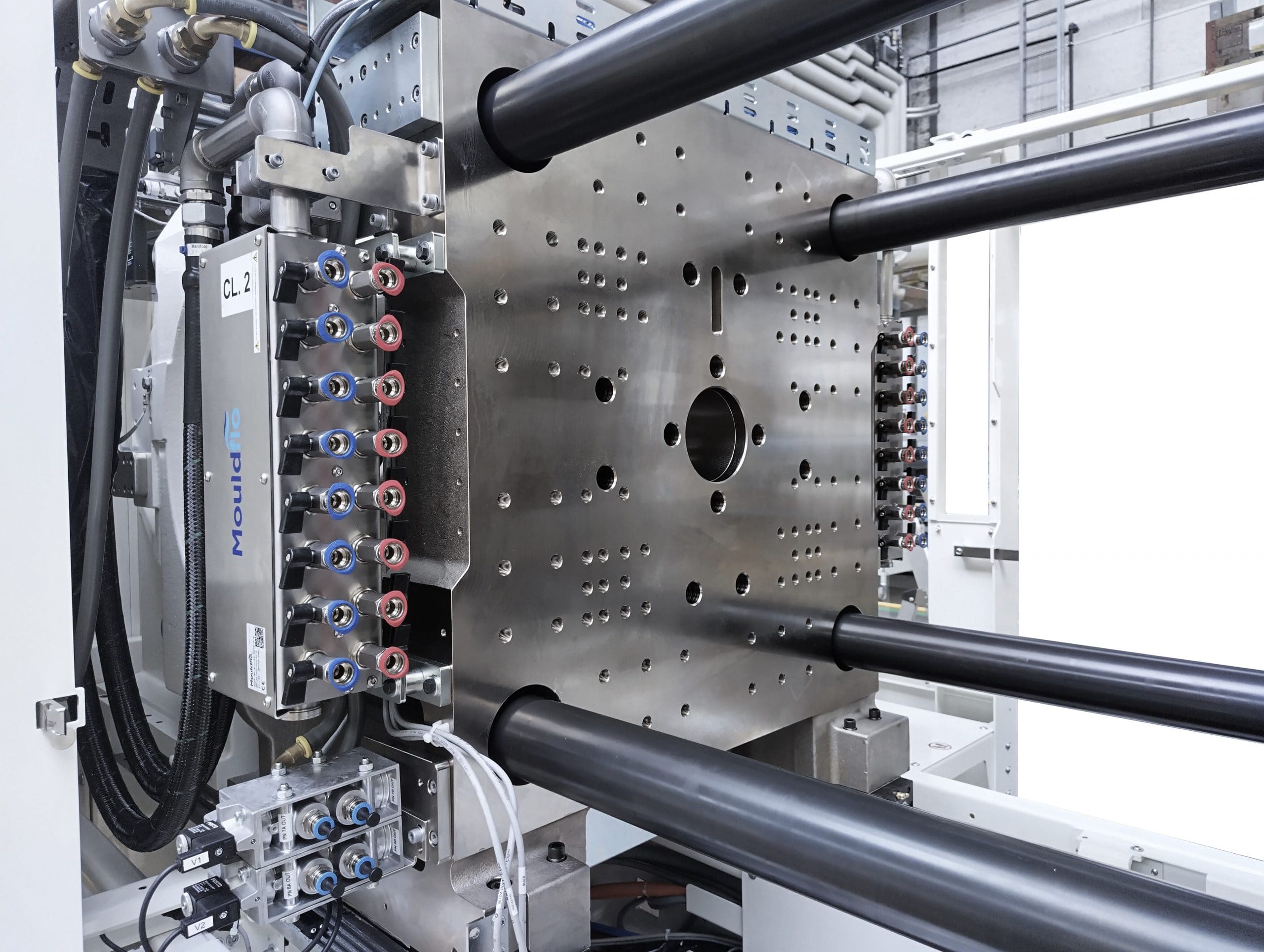

What makes it special is that, thanks to indexing technology with an integrated rotary unit and individually controlled, servo-electric needle shut-off nozzles, the cycle time is significantly reduced compared to conventional tools. Automation is handled by a 6-axis robot that removes the components when the tool is closed. Saxe’s compact solution includes optical quality control and automatic container changeover – fully integrated into the machine’s Axos control system. Tool cooling is also cleverly solved: Mouldflo water distributors integrated into the clamping plate record and monitor temperature differences and flow rates in real time.

Other partners involved in the exhibit are Ewikon (Hot runner technology), Petek (cleanroom technology), HB Therm (temperature control units), Piovan (material feed), Sabic (material), SAX Polymers (masterbatch) and bfa solutions (MES).

Exhibition information and appointment scheduling

Complete overhaul of a 10-year-old Elion 4200

Our revision department has done a great job and recently carried out a complete overhaul of an Elion 4200 injection molding machine.

Long-term compatibility of spare parts is guaranteed

The ten-year-old Elion 4200 shown here was rebuilt according to customer specifications. The machine was also upgraded to the latest software version. This increases system reliability and ensures the long-term compatibility of spare parts.

Ready for shipping

We are proud of the work done by our revision department. Now the machine is being prepared for loading. The machine goes to a packaging customer from Denmark.

Paving the way into the Netstal world with a used machine

With a used machine from Netstal, you can react flexibly to capacity bottlenecks. We offer you a selection of injection molding machines available at short notice for purchase and rental at any time.

Click on “Show used machines” below to go to the used machine marketplace. Gene Ifland will be pleased to advise you.

Frequently asked questions

Order spare parts conveniently via eService

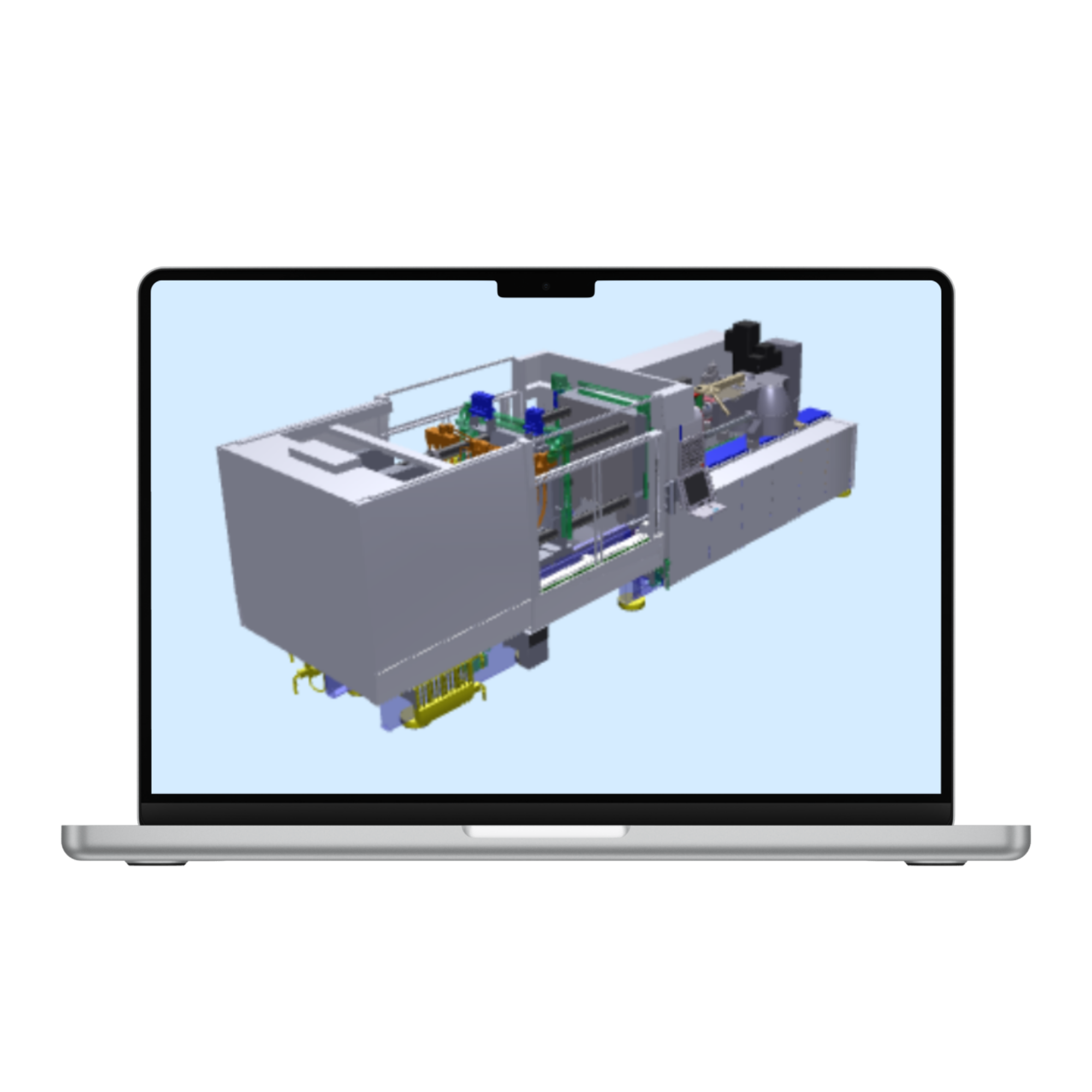

Spare parts for all Netstal injection molding machines can be conveniently ordered via our eService. Machines from 2007 onwards (except SynErgy machines) also benefit from a 3D catalog (see illustration). The 3D catalog makes it particularly easy to find the required spare part.

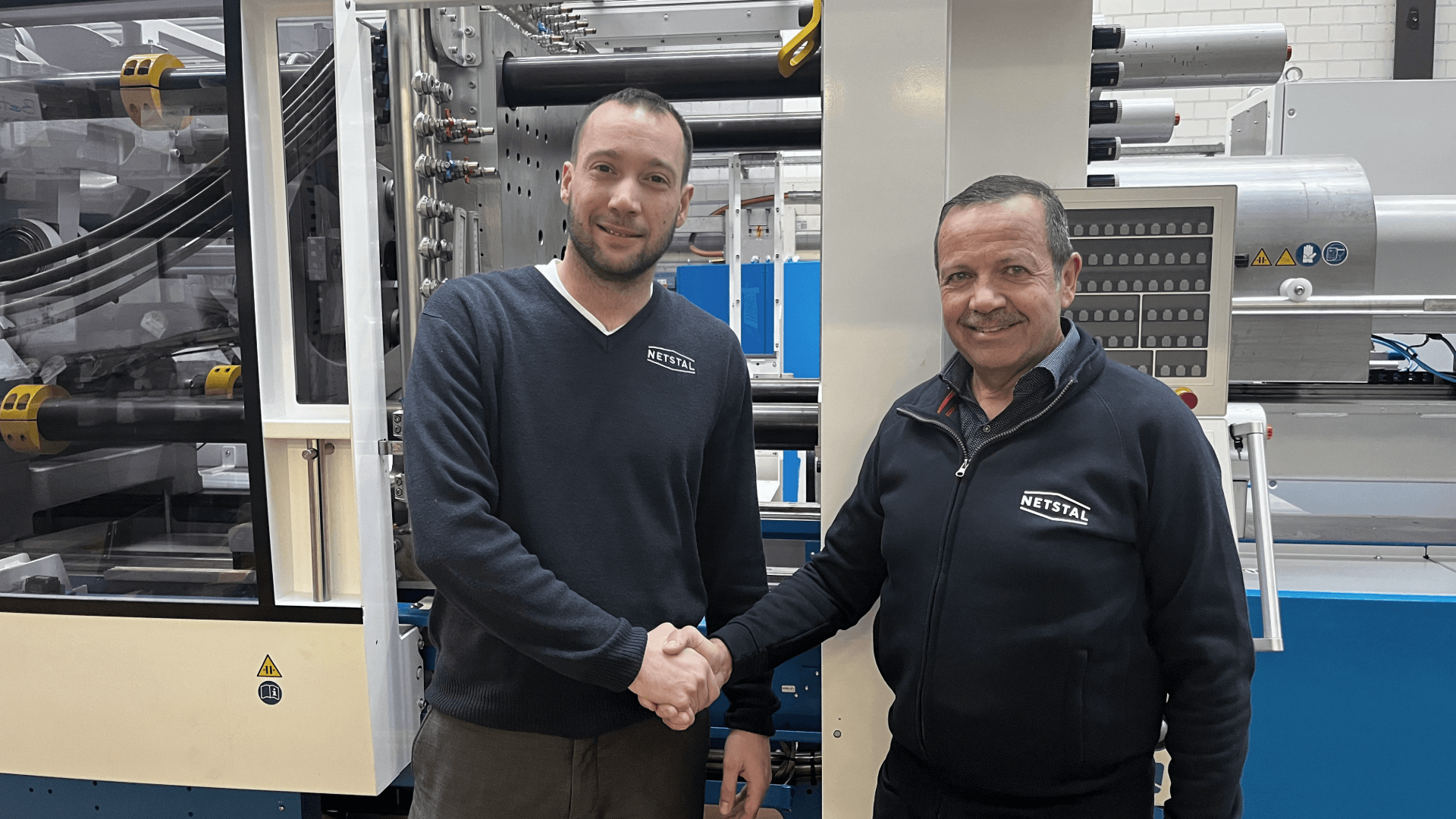

Gene Ifland takes over as Sales Manager Used Machines

After several decades at Netstal, Fritz Beglinger steps down as Sales Manager for used machines. A very competent and experienced successor has been found in Gene Ifland.

Fritz Beglinger has been with Netstal since 1976 and has achieved a great deal within the company. Over the past decades, he has successfully built up the used machine business for Netstal.

Fritz Beglinger and Gene Ifland with the revision team in 2025

Knowledge transfer ensured

Fritz Beglinger will be succeeded by Gene Ifland, who has been working as an application engineer at Netstal since 2011 and has a wealth of experience in working with Netstal machines. As an application expert, Gene Ifland has worked for customers and at trade fairs all over the world. Fritz Beglinger will continue to support Gene Ifland for a while with a reduced workload. A smooth handover and optimum transfer of knowledge are guaranteed.

„I would like to take this opportunity to thank you all for the wonderful and challenging collaboration. I loved my job and will miss all the great contacts and collaboration. Another phase of my life has begun and I will enjoy my free time with many other activities.“

Fritz Beglinger

„It is an honor for me to follow in Fritz Beglinger’s footsteps. I would like to take this opportunity to thank you for the trust you have placed in me. I am very much looking forward to working closely with our customers and the opportunity to use my many years of experience at Netstal to offer them the best possible and sustainable solutions.“

Gene Ifland

Paving the way into the Netstal world with a used machine

With a used machine from Netstal, you can react flexibly to capacity bottlenecks. We offer you a selection of injection molding machines available at short notice for purchase and rental at any time.

Click on “Show used machines” below to go to the used machine marketplace. Gene Ifland will be pleased to advise you.

Experience Netstal at Plástico Brasil

Plástico Brasil will open its doors at the São Paulo Expo from March 24 to 28, 2025. Visit Netstal at booth D078 and find out how we can optimally support you on your journey to maximum production efficiency.

Header image: Feira Plastico Brasil

The demand for high-quality packaging for food and beverages has been rising steadily in South America for several years. The same applies to components for medical devices and diagnostics. Netstal is growing accordingly in the region because more and more plastics processors want to take advantage of our leading injection molding technology and outstanding service support. With Netstal, manufacturers of PET preforms, beverage closures, thin-wall packaging and medical products are able to maximize their production efficiency reliably and sustainably.

Visit us at Plástico Brasil at stand D078 and find out how we can support you:

- Maximize productivity: With technology from Netstal, you produce in higher quantities than ever before. You produce reliably with the shortest cycle times in long-term continuous operation.

- Minimize unit costs: With our highly efficient injection molding systems, you reduce your unit costs and increase your competitiveness in a competitive market environment.

- Reduce energy costs: Thanks to the recuperation of kinetic energy and the optional system pressure reduction, Netstal machines impress with the lowest energy consumption compared to the competition. You save energy costs and reduce your ecological footprint.

- Increase availability: Our recipe for success to increase your system availability. Reliable technology that produces at maximum speed and with maximum precision. If the worst comes to the worst, our service team is there to support you, either on site or online.

- Enable circular economy, optimize sustainability: With Netstal you improve the ecological balance of your products. On our PET-Line, you can easily process up to 100% rPET in a large process window. And for thin-wall packaging, you can achieve additional material savings or process a higher proportion of recycled material with our Elios or Elion.

We look forward to discussing your next project with you and developing a customized injection molding solution for your application.

Schedule an appointment:

We look forward to your inquiry and will get back to you as soon as possible.

Netstal is the official wreath partner of the ESAF 2025 Glarnerland+

From August 29 to 31, Glarnerland+ will be swinging and celebrating: A stone's throw from our headquarters, the Swiss Wrestling and Alpine Festival (ESAF) will take place on the grounds of Mollis Airport. As a company firmly anchored in the region, Netstal supports the organizing committee and is a proud wreath partner of the ESAF 2025 Glarnerland+.

This is Swiss tradition at its best: the Swiss Wrestling and Alpine Festival, or ESAF for short, takes place every three years at different locations and regularly attracts over 400,000 spectators, making it the largest recurring sporting event in Switzerland. At the ESAF, the country’s best wrestlers compete in traditional Swiss wrestling, accompanied by competitions in stone put and a great festival culture with yodelers, flag-wavers and alphorn players. The winner receives the prestigious title of “Schwingerkönig” (wrestling king) as well as a live prize of a full-grown bull, the so-called “Muni”.

Pictures: ESAF 2025 Glarnerland+ / Maya Rhyner

Netstal’s support for the ESAF 2025 Glarnerland+

Holding such a large event is an organizational tour de force for which a good spatial infrastructure is indispensable. The ESAF organizing committee has been using meeting rooms at the Netstal headquarters for meetings and other presentation events since 2021.

A temporary shuttle service will be set up in the region to transport visitors between the more distant train stations, camping and parking areas and the festival grounds. The necessary bus terminal will be set up in the Netstal parking lot. In addition, our area will be used as a disposition point for the large festival parade, which traditionally takes place at the start of the ESAF.

Great sport against a magnificent mountain backdrop. The ESAF 2025 Glarnerland+ will take place on the Mollis airport site. A little further north are the Netstal factory halls (Photo: ESAF 2025 Glarnerland+ / Maya Rhyner)

As official wreath partner, we are looking forward to a fantastic ESAF 2025 Glarnerland+.

The + stands for the Zürichsee-Linth, March Höfe and Sarganserland regions bordering the canton of Glarus, which are also supporting ESAF 2025.

Beverage closures: System pressure reduction achieves 14.6 % energy savings

Reduce energy consumption with the adaptive system pressure reduction from Netstal. With the retrofittable option, you can reduce manufacturing costs and lower your company's CO2 footprint.

Initial situation:

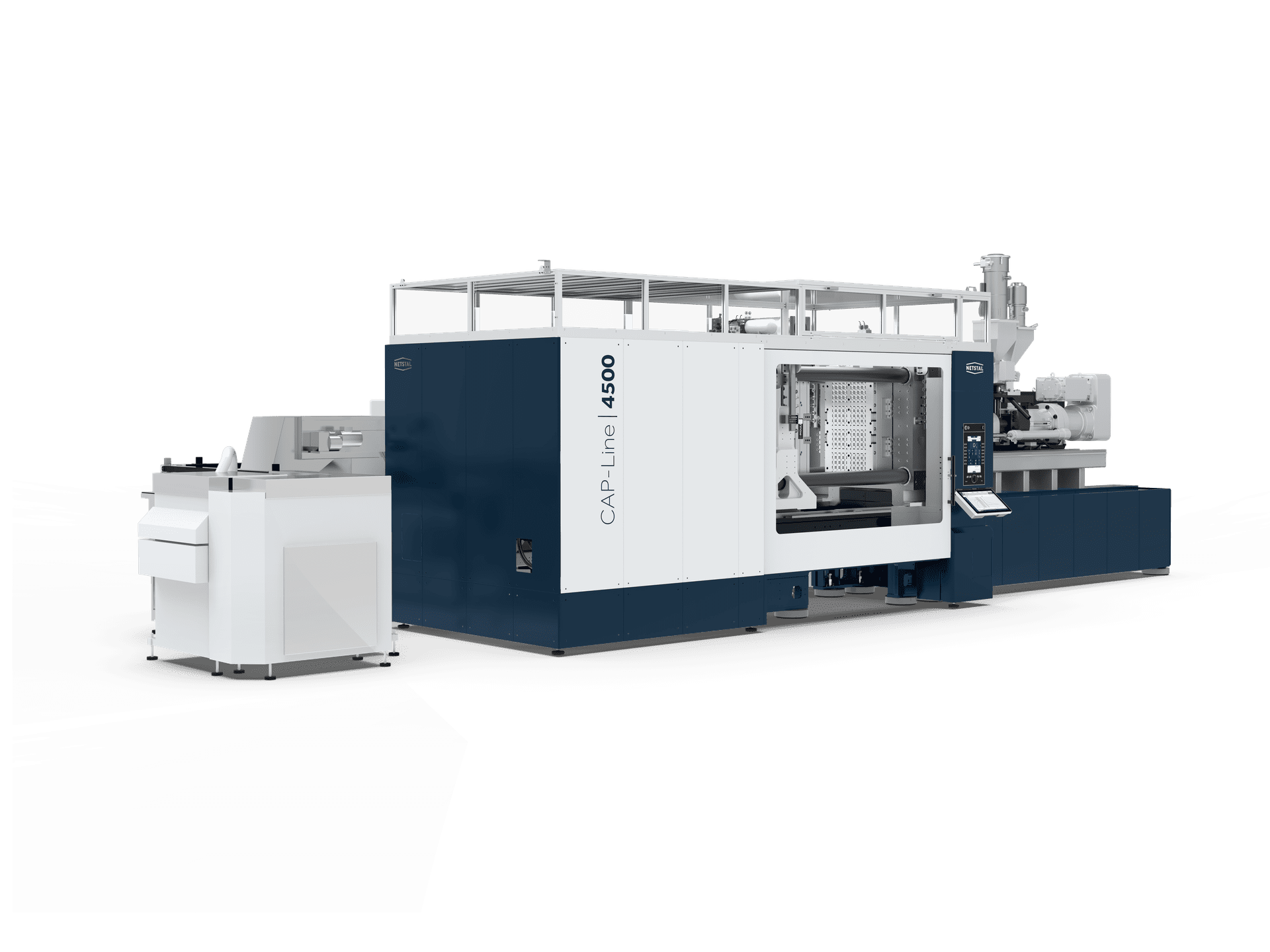

This case study is about a 26/22 cap for carbonated beverages (GME 30.38), which is produced with a 96-cavity mold on an CAP-Line 4500-2900 (Elios). The HDPE cap weighs 1.46 grams and the cycle time is 2.95 seconds.

Solution from Netstal:

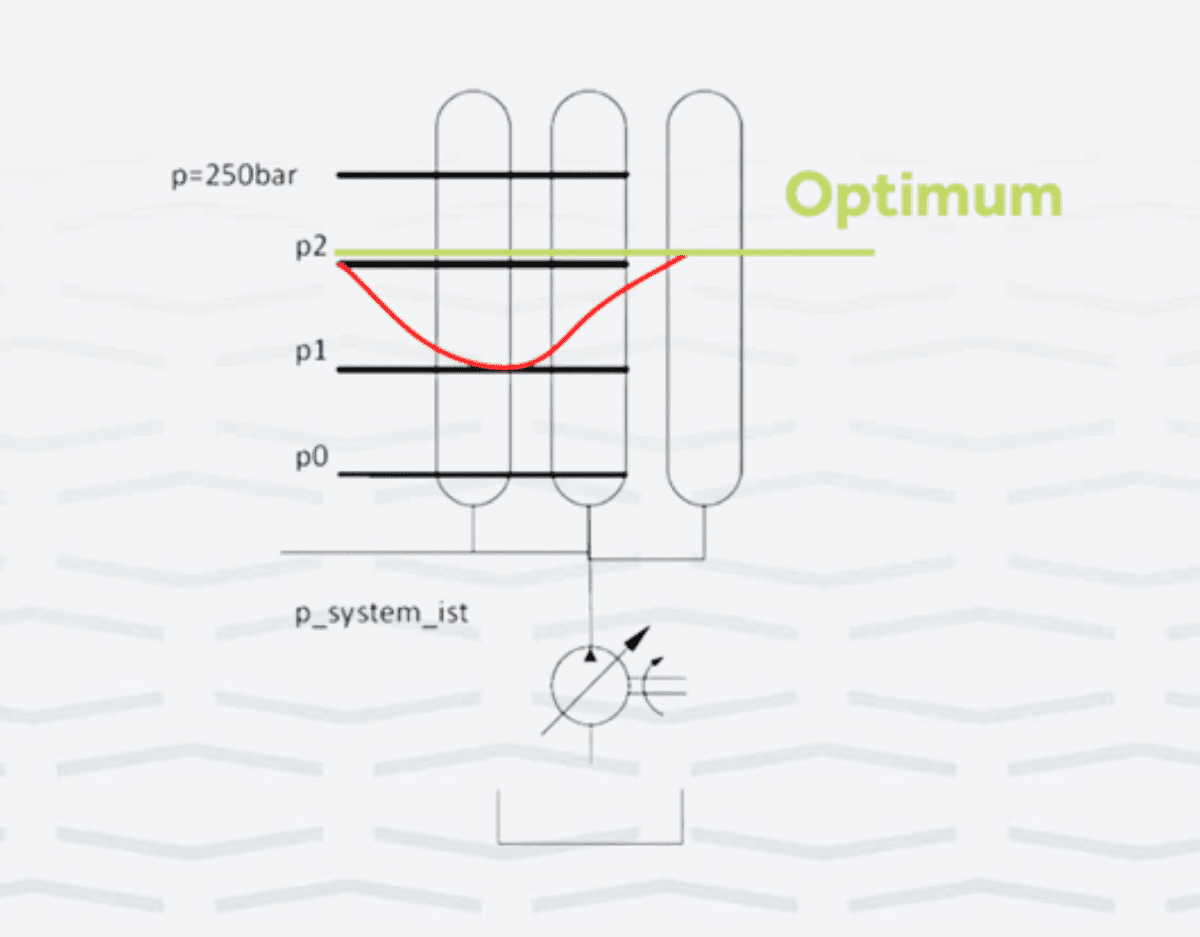

With active system pressure reduction, the energy consumption of the machine was reduced by 14.6 % in our comparative test. Due to the reduced adaptive system pressure, which is always based on the optimum operating point, only as much hydraulic energy is provided as is necessary for the product (see information box below).

In the test run, we were able to impressively demonstrate that production becomes more energy-efficient without any loss of stability and reliability. The system pressure reduction leads to lower operating costs, more sustainable production and is quickly amortized.

Chart legend:

- p2 = upper system pressure (today 250bar)

- p1 = lower working pressure or system pressure

- p0 = precharge pressure

Adaptive system pressure reduction

The hydraulic system of Netstal injection molding machines is designed for a maximum operating pressure of 250 bar in order to be able to cope with peak loads without any problems. Depending on the application requirements, a lower pressure would also be sufficient. In this case, this was an operating pressure of 170 bar, which ensured an optimum effect with the still high basic dynamics of the injection unit. This is where Netstal comes in with the new system pressure reduction and optimizes energy efficiency. In automatic mode, the adaptive control system determines the optimum point at all times and adjusts the system pressure accordingly. The energy consumption for providing the system pressure is reduced to a sensible minimum while maintaining the same level of productivity. This saves electricity costs, improves economy and reduces the CO2 footprint of your production.

Reproducible mold cooling in the production process

The functionality of injection molding machines is constantly evolving, and digitalization (Industry 4.0) in particular is opening up a host of new possibilities for networking and optimizing the production environment of injection molding machines. The basis for these new possibilities is data collected during the injection molding process.

The sophisticated measurement and control technology of modern injection molding machines today allows a deep insight into the manufacturing process. Process-relevant variables such as pressures, speeds and temporal processes can now be recorded, analyzed, evaluated and monitored very precisely. In addition, the correlations with the associated mold-internal processes are known so that the filling and demolding process can be precisely controlled. In contrast, the thermal processes that occur in injection molding are still relatively unknown or at least not easily accessible for more precise analyzes. Thus, mold cooling is an area that still leaves many questions unanswered and in which there is still a lot of potential for optimization.

Recording and monitoring of thermal parameters

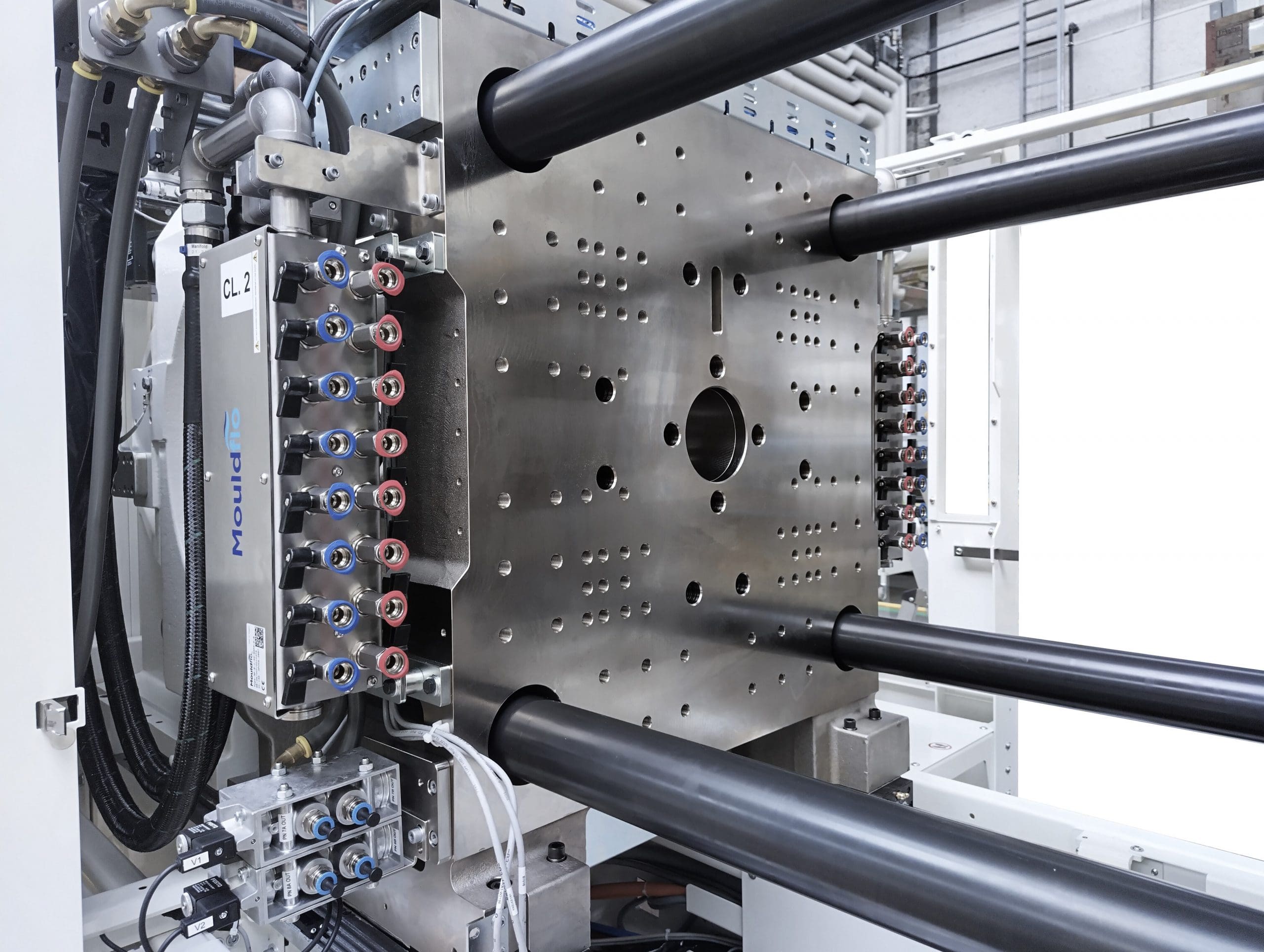

Even today, machines are often equipped with simple cooling water distributors or mechanical water batteries, which, at best, allow the water flow to be visually monitored using a float. With the new cooling water monitoring system, Netstal offers a flexible and powerful solution. At the heart of the monitoring system are the fully integrated and extremely compact measuring manifolds from the Danish industry leader Mouldflo. The cooling water distributors, specially designed for high-performance applications, can be mounted flexibly and as required on all sides of the clamping plates and enable the recording of all relevant measurement data for mold cooling. They are also seamlessly integrated into Netstal’s media supply concept.

The new water distributors from Mouldflo, specially designed for high-performance applications, mounted on a clamping plate

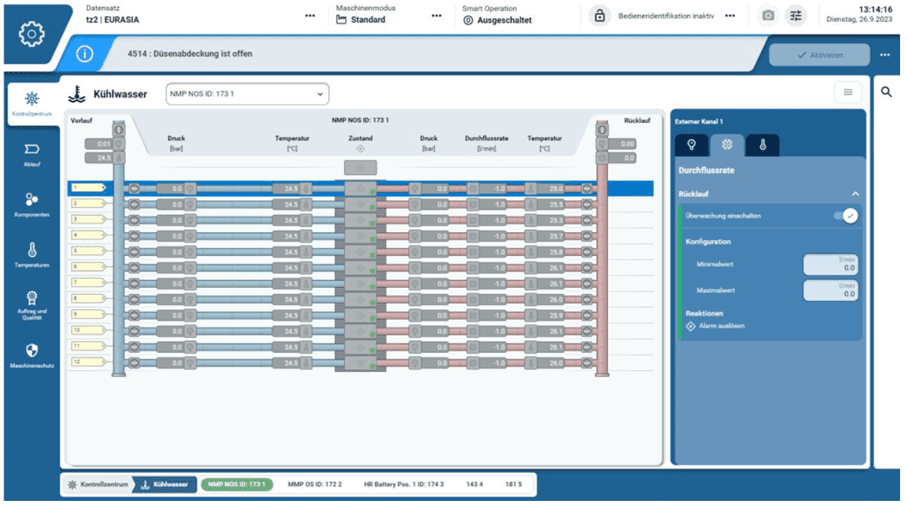

The water flow rates are measured using the so-called vortex principle, which enables flow measurement without moving parts. In addition to the flow rates per cooling water circuit, the inlet and outlet temperatures as well as the inlet and outlet pressure at the manifold are measured as standard. This data enables comprehensive recording and monitoring of the cooling processes in the mold. All measurement data is clearly displayed on one page on the Axos 9 control unit and provides a comprehensive overview of the status of the thermal processes in the injection mold at all times. Of course, all values can be provided with a monitoring tolerance so that the machine can detect immediately if something changes in the cooling conditions.

The overview page provides a complete overview of the current status of the cooling water monitoring system

Production reliability is everything

Together with the new cooling water monitoring system from Netstal, the customer has a complete overview of all quality-relevant process parameters. Using the flexible and application-specific configurable process monitoring module from Axos (Q-page), this data can now be used to effectively monitor the production process. In addition to a detailed statistical evaluation, all data can be provided with a monitoring tolerance. In the event of deviations, the machine can react with an alarm or with a freely programmable procedure. This way ensures that the machine reliably delivers the required quality.

Digital networking via OPC-UA

The network-based communication standard OPC-UA is becoming increasingly established in the plastics industry. Various interfaces are already available between the system components involved, such as the interface to temperature control units provided in accordance with the Euromap 82.1 recommendation. In addition, the host computer interface in accordance with Euromap 77 forms the most important communication platform “to the outside world”, e.g. to overarching control systems. This digital networking means that all data recorded by the machine is available at all times and can be used to track and document the entire production system, including the cooling water monitoring data.

Future potential for increasing efficiency

At the moment, the focus is on ensuring product quality. However, the new possibilities created by the recording of process data and networking also help to optimize processes, reduce energy consumption and further improve efficiency. Netstal is at the forefront here and proves this time and again with innovative solutions. At Netstal we are constantly working on innovative solutions to further maximize the production efficiency of our customers.

So give us a challenge and let you us discuss together how we can support you in optimizing your value chain.

Fakuma 2024

Experience the reproducible Mouldflo mold cooling system in production use at Fakuma 2024. You can find all information about our presentation on our event page.