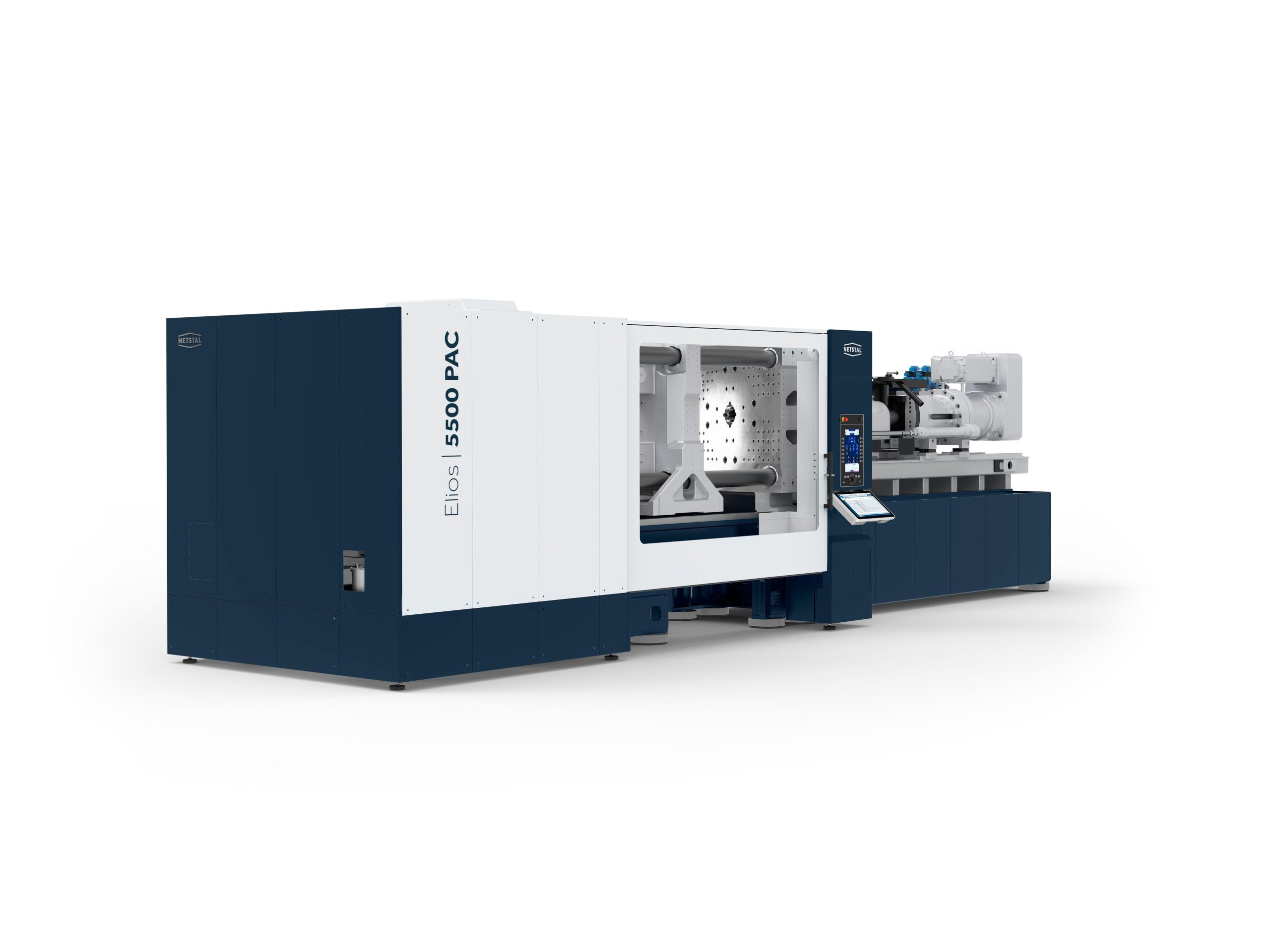

When international experts come together at K 2025 in Düsseldorf, Netstal (Hall 15, Booth D24) will be showcasing a highly efficient system solution to produce 1-liter IML pails. The focus is on the Elios 5500 PAC, which has been optimized for packaging applications and sports a clamping force of 5500 kN. Netstal combines leading energy efficiency with the highest precision and stable process consistency. Users benefit from maximum efficiency and quality.

Plastic pails with IML (In-Mold Labeling) have been a common and widely used form of packaging for yoghurt products with a desired filling volume of 1 liter for many years. This packaging technology offers decisive advantages over other materials such as a high-quality appearance, improved recyclability, high material efficiency and a reduced CO₂ balance. Netstal has played a pioneering role since the advent of IML technology and has played a decisive role in shaping the development of this segment over the past decades. Netstal has always focused on optimizing packaging efficiency: the ability of packaging to fulfil its functions while minimizing material use, costs and environmental impact.

Elios series provides the highest performance for optimum packaging efficiency

For example, the 1-liter IML pail made of polypropylene (PP) produced at K 2025, which is provided by material partner Sabic, shines with an enormously low weight of only 23 grams. By comparison, according to internally documented reference applications, 15 grams more material had to be used for every pail 20 years ago. To be able to reliably fill the channels in the mold for such thin walls and with fast cycle times, the injection molding machine must offer particularly high injection performance and dynamics. Netstal’s Elios series offers the necessary performance characteristics and has been the benchmark for thin-wall packaging since its market launch in 2016. The Elios 5500 PAC with a clamping force of 5500 kN will be used at K 2025. The hybrid injection unit with two-valve technology offers an injection speed of up to 1100 mm/s in “High Power” mode and a maximum injection pressure of 2400 bar. The high-precision RFC injection control system with its dynamic control resolution in the millisecond range ensures constant part weight within tight tolerances.

Powerful and energy-efficient: The Elios 5500 PAC produces a thin-walled IML pails at K 2025

Recycling optimized IML packaging

The best conditions for the efficient production of the 1-liter IML pail with a wall thickness of only 0.35 mm in a 4-cavity mold from the Dutch system partner and IML expert Brink. Brink also provides an integrated side-entry handling system. The high-speed automation inserts the labels into the cavities of the mold and removes the finished pails, subjects them to a camera inspection and finally stacks them on a conveyor belt. The NextCycle IML labels from partner MCC Global are optimized for recycling and approved accordingly by the Recyclass organization. The PP label is completely detached in the mechanical recycling process and therefore does not affect the polypropylene value stream.

The 1-liter yoghurt pail weighs just 23 grams

Powerful and energy-efficient clamping unit

With a cycle time of 3.8 seconds, around 3800 parts per hour are produced. The robustly designed and dynamic clamping unit with 5-point double toggle lever ensures long-term stability for harmonious and mold-gentle driving movements under high loads. The dry cycle time of the 5500 kN machine is a fast 1.7 seconds. With its tie bar distance of 920 mm x 920 mm and 901 mm opening stroke, the Elios 5500 PAC also accommodates larger molds without any problems. With its hybrid drive concept and energy recuperation, the machine offers a leading energy efficiency. The kinetic energy generated during braking flows into the electric motor of the main drive, where it is converted into hydraulic energy and stored. Even under full load, customers save up to 50% electricity compared to a fully hydraulic machine.

With the optionally selectable system pressure reduction, energy efficiency can be further increased while maintaining productivity. With this option, the maximum system pressure in the hydraulic system is permanently adjusted at the optimum point. This reduces energy consumption and lowers also the load on technology, which can have a positive effect on availability. The benefit of system pressure reduction depends primarily on the difference between the maximum system pressure of the machine and the actual pressure required in the application in question.

Intuitive machine operation and digital solutions

With the Axos 9 control system, users can operate the fully integrated production cell particularly intuitively and thus exploit the maximum performance potential of the machine. The needs-based operation offers situation-specific and optimal user experience both for the operating personnel in the production environment and for the programming of the applications. The optionally available four-button Smart Operation feature also enables simplified and safe machine control in the production environment. Digital additions such as the free Netstal eService and the fee-based Netstal Remote Control round off the product range. To enable standardized data exchange and integration into its own infrastructure, Netstal equips all current machines with the common Euromap interfaces based on OPC-UA. Digital partner bfa solutions will showcase efficient integration by connecting both injection molding machines on display at the Netstal booth to its own MES solution.

The material feeder from Piovan and the chiller from ef cooling complete the attractive and highly efficient exhibit.