The Evolution of EfficiencyThe New Elion MED

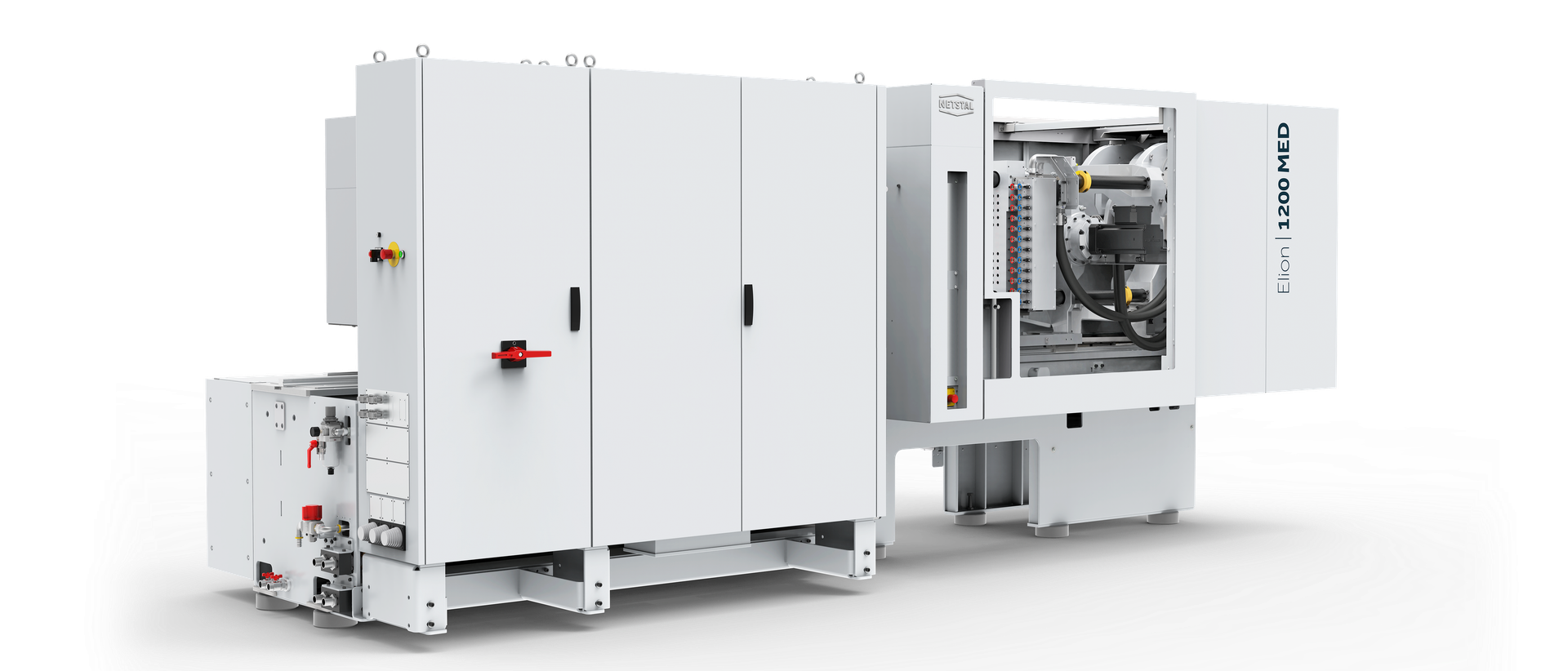

The new Elion MED impresses with its shortened design, optimized toggle lever geometry and a new injection gearbox. This allows you to produce with maximum efficiency on a smaller footprint.

Please accept YouTube cookies to play this video. By accepting you will be accessing content from YouTube, a service provided by an external third party.

If you accept this notice, your choice will be saved and the page will refresh.

Highlights

- Clamping force: 1200 kN, 1750 kN (target portfolio: 800 – 4200 kN)

- Compact, much shorter design compared to the predecessor model

- Complies with cleanroom class ISO 7 as standard (higher classes can be configured individually)

- Optimized toggle lever geometry with double connecting rod for improved force distribution

- Modified protective cover for optimum accessibility

- Optimized media supply and integration of Mouldflo measuring manifolds

- New and particularly energy-efficient direct drive for unit movement and the application of nozzle contact pressure

- RFC injection control for leading shot-to-shot consistency

- Optimized quality monitoring

- Robust design for maximum reliability and availability

- Optimum energy efficiency thanks to recuperation of kinetic energy

Your Benefits

High performance on a small footprint

We have consistently optimized all modules for a compact footprint. The result is a significantly shortened machine that offers an outstanding level of performance and a great deal of flexibility for a wide range of applications with identical clamping force.

Leading Precision

High-precision sensors with an extremely high 2 kHz sampling rate enable unrivaled precision and reproducibility. The newly revised quality monitoring system ensures seamless monitoring and assurance of production quality.

Maximum Reliability

Netstal machines are particularly durable. With the new Elion, we have further developed proven concepts. The machine has an extremely solid design. This enables us to meet your high requirements so that you can produce continuously for many years without any loss of performance.

Maximum Efficiency

The servo drives we use offer you the best energy efficiency. With the newly designed servo-hydraulic direct drive for unit movement and the application of contact pressure, we have once again significantly increased the energy efficiency of the Elion.

Highest level of cleanliness

Thanks to fully encapsulated and water-cooled drive motors and hermetically sealed control cabinets, the new Elion is virtually emission-free. We have designed the entire machine with a new protective cover for optimum cleaning. As standard, you can use the Elion MED in cleanrooms up to class 7. Higher cleanroom classes are also possible with additional equipment options.

Open and connected

The new Elion offers all modern interfaces based on OPC-UA for connectivity with central control systems and the various peripheral components. Thanks to HTML 5 integration, even more complex system components can be easily integrated into the machine control system.

Please accept YouTube cookies to play this video. By accepting you will be accessing content from YouTube, a service provided by an external third party.

If you accept this notice, your choice will be saved and the page will refresh.

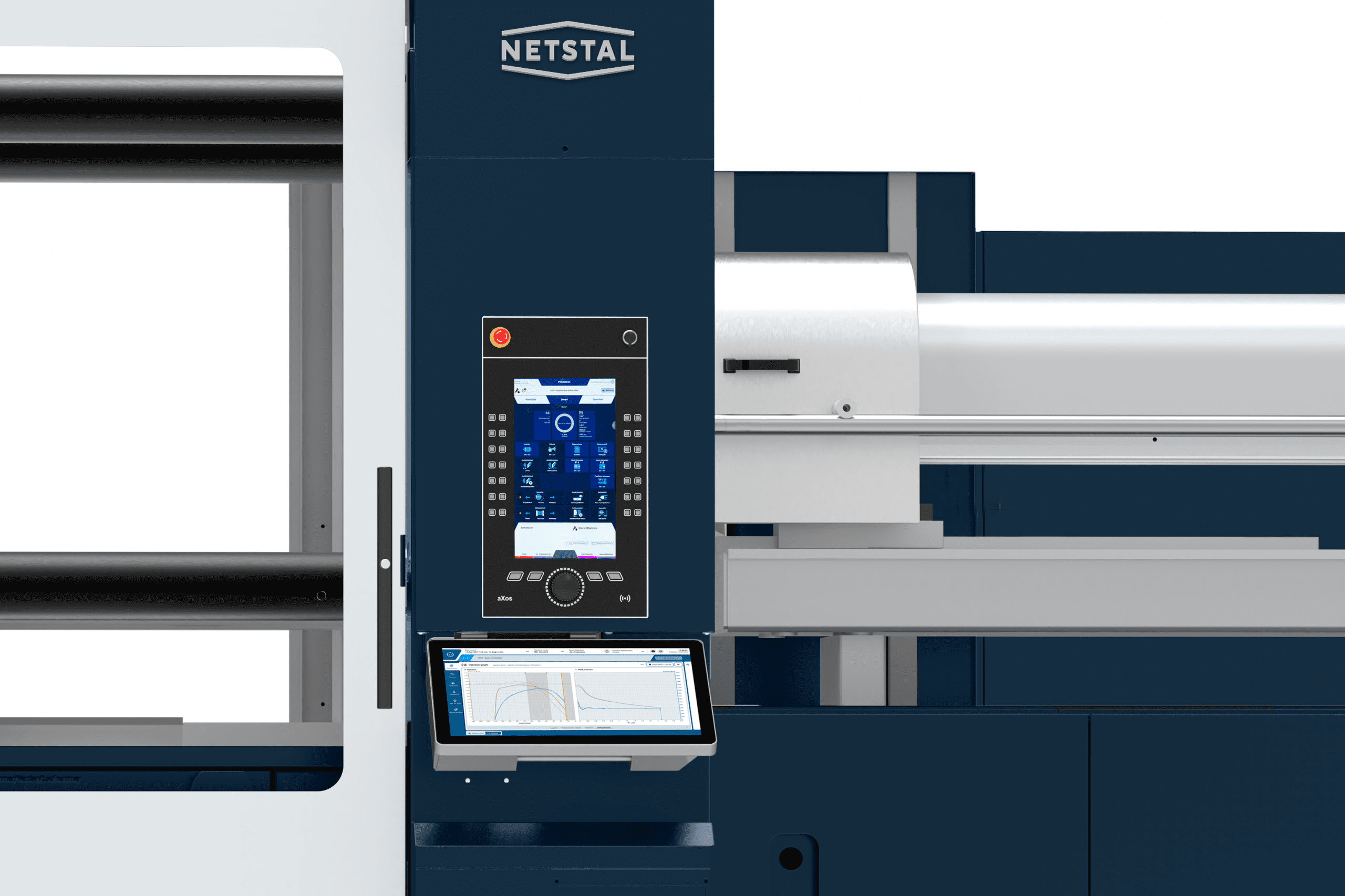

Axos controller

Our Axos 9 controller allows you to get the most out of your Netstal machine.

We developed the controller to meet the increasingly complex requirements of contemporary and future applications. Numerous innovative functions support straightforward, fast and faultfree operation within the production environment.

Need-based operation provides an optimal and settingspecific user experience for operators within the product environment as well as in application programing.

Thanks to the advanced hardware combination and new temperature control, we achieve the highest quality in terms of production parts as well as a concurrent reduction in energy.

The integrated Four-key Smart Operation control panel enables simple and safe machine control within the production environment. Operating errors are reliably avoided. Smart Operation lastingly increases the overall equipment efficiency of your injection molding production.

Applications

Digital solutions

Netstal eService

Maintain peak production efficiency with our free eService. All machine specific documentation is provided here. Quickly identify and order the required spare parts with the 3D spare parts catalog. Use the ticketing system to directly request our support if required.

Netstal Remote Control

Access your machine controls at any time with Netstal Remote Control (NRC). Even complex application process settings can be adjusted remotely. Machine checks at change of shift can be carried out from the office to save the walk through the machine park. Use the collaborative potential to make internal technical assistance available oncall 24/7 and across all locations to support other plants.

Standardized data exchange

The Euromap 77 standard specifies the interface between injection molding machines and the overriding production control system. Systems (MES, ERP, QM, etc.). The basis for Euromap 77 and other Euromap interfaces for integrating periphery systems, such as Euromap 82.1 for temperature control devices and Euromap 82.2 for hot runner control devices, is OPC UA, one of the most widely used Industry 4.0 protocols. OPC UA enables standardized, manufacturerindependent and efficient data exchange between machines, devices and other systems within the industrial environment.